Model

5CKWS20AR

5CKWS25AR

5CKWS30AR

5CKWS40AR

5CKWS50AR

Coupling Unit

5WSS16AR

5WSS20AR

5WSS25AR

5WSS30AR

5WSS40AR

5WSS50AR

Nominal Cooling Capacity

Btu/hr

16000

20000

25000

30000

38500

51500

kW

4.68

5.86

7.32

8.78

11.27

15.08

Nominal Heating Capacity

Btu/hr

16500

20500

25500

31000

41500

54500

kW

4.83

6.03

7.47

9.08

12.15

15.96

Unit Nett Weight

kg

31 + 4

32 + 4

35 + 4

38 + 4

40 + 4

Fan Motor

6 Poles x 35W

6 Poles x 50W

6 Poles x 65W

6 Poles x 85W

6 Poles x 120W

Fan Blower

Air flow rate (high speed)

m

3

/min

20.9

22.1

24.9

28.0

29.5

Refrigerant Circuit

Liquid valve connection

inches

1/4

1/4

3/8

3/8

3/8

Gas valve connection

inches

1/2

5/8

5/8

5/8

5/8

Drain Pipe Connection

inches

3/4

3/4

3/4

3/4

3/4

Air Filter

WASHABLE SARANET FILTER

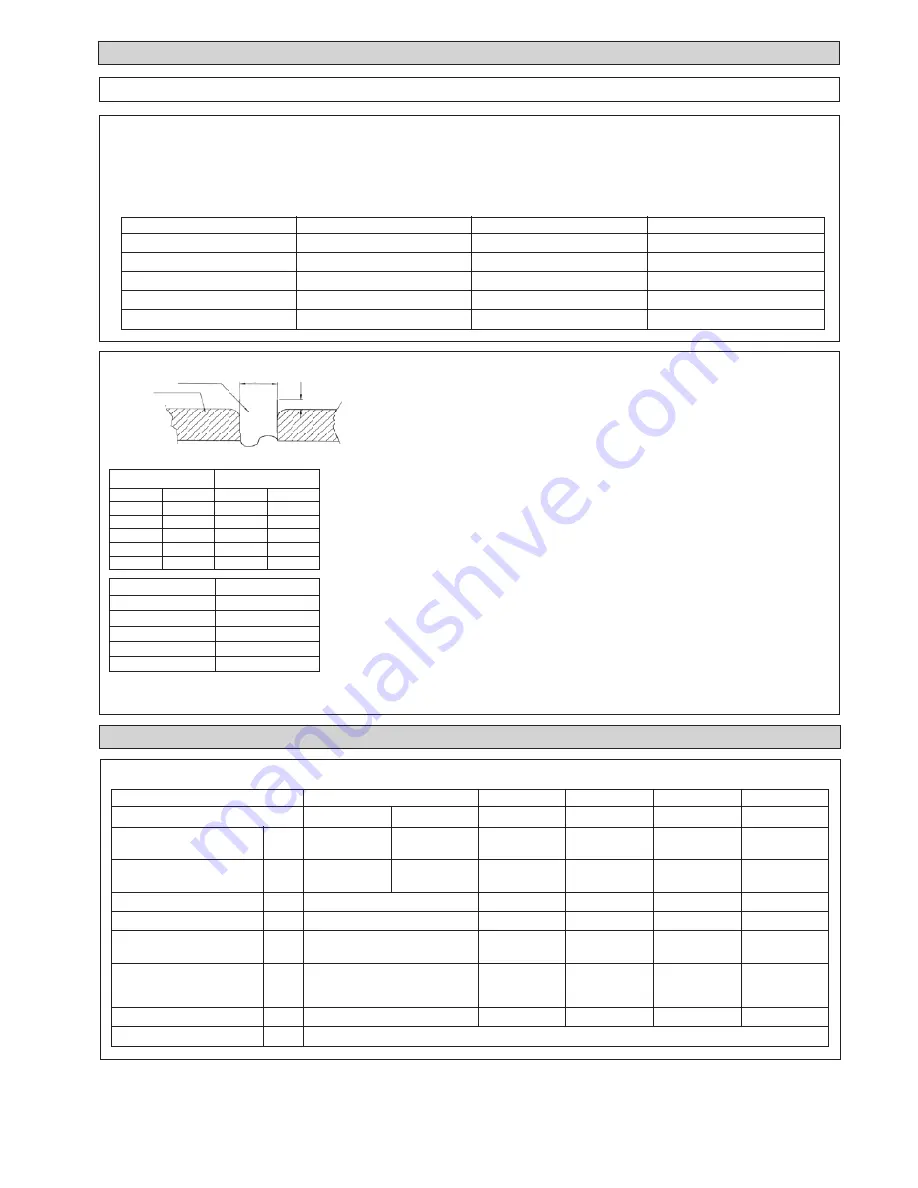

Ø Tube, D

A (mm)

Inch

mm

Imperial

Rigid

1/4"

6.35

1.3

0.7

3/8"

9.52

1.6

1.0

1/2"

12.70

1.9

1.3

5/8"

15.88

2.2

1.7

3/4"

19.05

2.5

2.0

REFRIGERANT PIPING WORK

Refrigerant piping is important in particular. Refrigerant cycle of the split air conditioner is realized by the perfect piping work.

1. Piping Length And Elevation

•

If the piping is too long, both the capacity and reliability of unit will drop.

• As the number of bends increase, resistance to flow of refrigerant system increases, thus lowering cooling capacity and as a

result the compressor may become defective.

• Always choose the shortest path and follow the recommendation as tabulated below.

Model

5CKWS20AR

5CKWS25AR

5CKWS30/40/50AR

Maximum Length (m)

15

15

35

Maximum Elevation (m)

8

8

10

Maximum No. of Bends

10

10

10

Liquid Pipe Size

1/4”

1/4”

3/8”

Gas Pipe Size

1/2”

5/8”

5/8”

Copper tube

Swaging block

Pipe Size mm / (in)

Torque Nm / (ft - lb)

6.35 (1/4)

18 (13.3)

9.53 (3/8)

42 (31.0)

12.7 (1/2)

55 (40.6)

15.88 (5/8)

65 (48.0)

19.05 (3/4)

78 (57.6)

2. Piping Connection

•

Do not use contaminated or damaged copper tubing. If any piping, evaporator

or condenser had been exposed or had been opened for 15 seconds or more,

then vacuum and purge with field supplied refrigerant. Generally, do not re-

move plastic, rubber plugs and brass nuts from the valves, fittings, tubing and

coils until it is ready to connect suction or liquid line into valves or fittings.

•

If any brazing work is required, ensure that nitrogen gas is passed through coil

and joints while the brazing work is being done. This will eliminate soot forma-

tion on the inside wall of copper tubings.

•

Cut the pipe stages by stages, advancing the blade of pipe cutter slowly. Extra

force and a deep cut will cause more distortion of pipe and therefore extra burr.

•

Remove burrs from cut edges of pipes with a remover. This will avoid uneven-

ness on the flare face which will cause gas leak.

•

Flare the pipe with extra length above the flaring tool as shown in the table

beside.

•

The flared edge must be even and not cracked or scratched.

•

Align the center of the piping and sufficiently tighten the flare nut with fingers.

Finally, tighten the flare nut with torque wrench until the wrench clicks.

•

Be sure to execute heat insulation. (Polyurethane form with thickness more

than 15mm)

•

Except the water source heat pump unit which is pre-charge with refrigerant,

the fan coil unit and the refrigerant connection pipes must be purged because

the air that contain moisture remaining in the refrigerant cycle may cause mal-

function to the compressor.

PHYSICAL DATA

R410A – Heat Pump

D

A