6

McQuay IM 777-1

Installation Guidelines

3

Seal the double-wall panel on each side with an industrial/

commercial grade silicone sealant or duct seal compound.

It is extremely important to seal each panel hole or

penetration securely so it is airtight and watertight and

there is NO EXPOSED FOAM INSULATION.

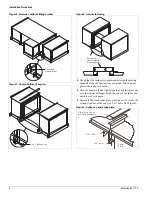

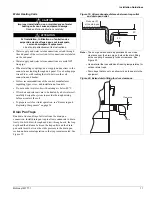

Figure 11: Cutting and sealing injected-foam insulated panels

Field Mounting Junction Boxes and Other

Components

For field mounting 4" × 4" or smaller junction boxes to the

standard panel exterior, use a minimum quantity of 4, 3/16"

diameter pop rivets.

Do NOT use self-tapping drill screws.

They will not tighten nor secure properly and panel

damage can occur.

If larger, heavier components require mounting on unit panels,

use through-bolts with flat washers through both outer and

inner panels. To maintain panel integrity, seal both ends with

an industrial/commercial grade silicone sealant or duct seal

compound.

The unit frame channel is another excellent location for

securing heavier components; self-tapping screws are not

acceptable. Ensure that the location permits the full operation

of all access doors and panels and does not interfere with other

vital components.

Duct Connections

Use flexible connectors on the outlet and inlet duct connections

of all units. Do not position down flow fans over air ducts that

are routed down into the building. Use a discharge plenum

when bottom connections are necessary. See Figure 12

.

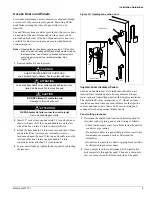

Figure 12: Discharge plenum

If the unit has a top mixing box or economizer damper or a top

duct connection, field fabricate and install flashing to divert

moisture from the connection. The flashing must lap over the

standing seams of the top panels. The flashing also must lap

over the side edges of the unit. See Figure 13

.

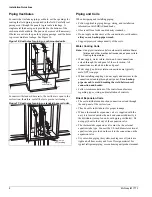

Figure 13: Flashing over top panels and sides of units

WARNING

Flame and smoke can cause equipment

damage, severe personal injury, or

death.

Before operating unit, seal all piping and

wiring holes on both inner and outer panels

with an industrial grade silicone sealant or

duct seal compound.

Do not use a cutting

torch or expose panel to fire

. Panel

damage can occur.

WARNING

La fumée et les flammes peuvent

endommager le matériel et causesr des

blessures graves ou la mort.

Avant d’utiliser le dispositif, obturer tous les

trous de passage de tubulures et de fils

ménagés dans les panneaux intérieurs et

extérieurs au moyen d’une pâte à base de

silicone ou d’un mastic d’étanchéite â

conduits de qualité industrielle.

Ne pas se servir d’un chalumeau coupeur ni

exposer les pannequx à une flamme nue

pour ne pas risquer de les endommager.

Cut hole from both sides of panel

Seal completely with silicone

sealant or duct seal compound

Prop 65—Substances in fuel or from fuel combustion can cause personal injury or death,

and are known to the State of California to cause cancer, birth defects or other reproductive harm.

D i s c h a r g e

P l e n u m

F l a s h i n g

D u c t

F l a s h i n g

U n i t t o p

p a n e l

F l a s h i n g

D u c t

F l a s h i n g

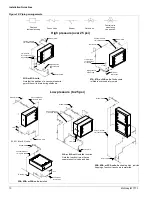

Summary of Contents for Skyline IM 777-1

Page 32: ...30 McQuay IM 777 1...

Page 33: ...McQuay IM 777 1 31...

Page 34: ...32 McQuay IM 777 1...

Page 35: ......