22

McQuay IM 987

Mechanical Installation

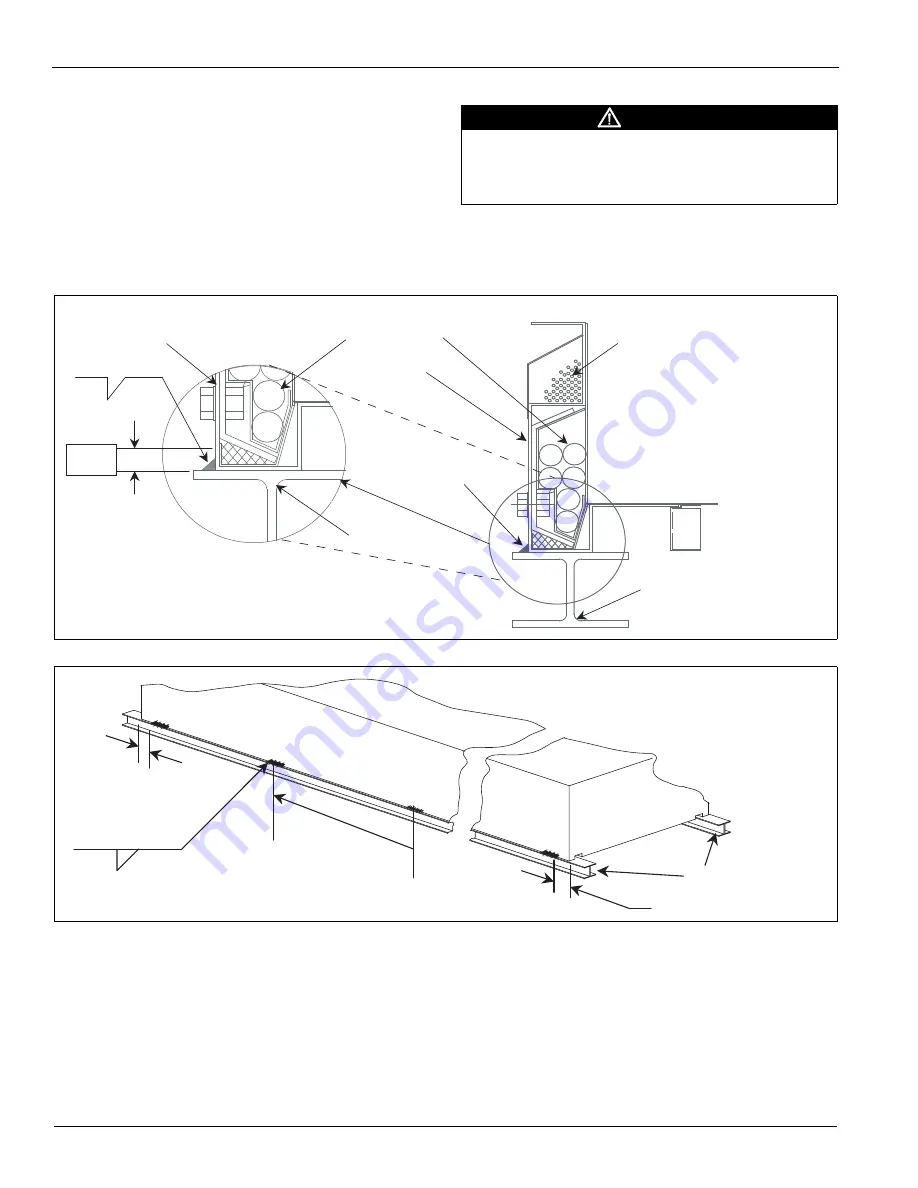

Post and Rail Arrangement

1

Set the rooftop unit on the rails. The rails should run

lengthwise and support the entire unit base.

2

Weld both sides of the unit directly to each rail as shown

in

Figure 24

and

Figure 25

. The total number of welds

required is dependent on the length of the unit.

a

Make the fillet welds 2 inches long, spaced 48 inches

apart on centers.

b

Place the end welds 6 to 12 inches from the unit edge.

Note:

High temperature insulation is installed at the factory to

allow for field welding along the lower front edge region

of the unit base.

Figure 24: Welding of Unit To Rail—Unit Base, Cross-Sectional View

Figure 25: Weld Locations for Rail Arrangement

CAUTION

When welding unit to the curb, do not damage wiring (control

panel side). Weld ONLY in the specified zone in the acceptable

weld zone (see

Figure 24

). Welding must comply with weld

fillet size, etc. as indicated in

Figure 24

.

2–48

Rail

.25

Unit power wiring

(by factory)

Unit control wiring

(by factory)

High temp

insulation

Rail

Acceptable weld zone

Field attachment

weld

Weld

zone

.50"

Unit base

Unit base

6–12"

2–48

Rooftop unit

.25

Weld every 48"

6–12"

Rails