6000XL Series Service and Installation Manual

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

18

Delfield

™

®

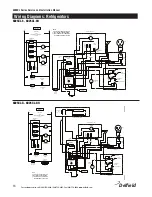

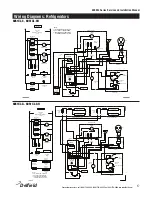

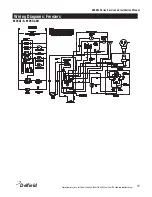

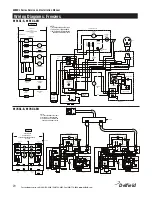

Wiring Diagrams: Refrigerators

6076XL-S, 6076XL-SH

6076XL-G, 6076XL-GH

REVISIONS

LOCATION

DIMENSIONS ARE IN INCHES

TOLERANCES

ALL PARTS TO BE DEBURRED AND EDGES

UNLESS OTHERWISE SPECIFIED

THIRD ANGLE

PROJECTION

The contents of this document are

PROPRIETARY TO THE DELFIELD COMPANY

and are not to be disclosed to others

intended without the written approval

or used for purposes other than

of The Delfield Company.

MATERIAL

PROPRIETARY

BROKEN .010 MAXIMUM.

ANG. ±

.XXX ±

.XX ±

.X ±

.010

.03

1

.1

C

DO NOT SCALE DRAWING

SCALE

SIGNATURE

PURCH:

MFG:

QA:

L ENNIS

CHECKED:

DRAWN:

05-MAY-2011

DATE

SIZE

DESCRIPTION

1

REV

DESCRIPTION

REV.

COVINGTON, TN

ENODIS

3

SHEET

OF

1

1

DWG. NO.

Reach-in Divison

DATE

APPROVED

PLUG

RECEPTICAL BOX

9294477

LED DISPLAY

CONDENSOR FAN

EVAPORATOR FAN

ENERGY SAVER

DOOR

SWITCHES

SWITCH

1.1,2,3 2.1,2,3 3.1,2,3

COMPRESSOR

RELAY

CONTROL

TEMPERATURE

LED DISPLA

Y

(IF USED

)

L

EV

AP C

OIL

SENSOR

SENSOR

CABINE

T AIR

1

C

FAN RELAY

CIRCUIT

CONTROL

6

F

5

N

INCANDESCENT

DOOR FRAME

LIGHT

HEATERS

HINGE

SWITCHES

DOOR

RED

BLK

DOOR FRAME HEATERS

L

3

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

1 2

C L

5

4

H N

6

F

W

W

W

(IF USED)

COMPRESSOR

M

M

M

CONTROL

BOX

P

SWITCH

ENERGY SAVER

GREY

BLUE

CABINE

T AIR

CONDENSER

FAN

BLK

BLK

M

GROUND

MOTOR PROTECTOR

COMPRESSOR

COMPRESSOR

WINDING

WINDINGRUN

14

12

STAR

10

13

11

CAPACITOR

START RELAY

START

EVAP FAN

WITH BLUE

STRIPES

W

W

BRN

BLK

W

M

MOTOR

EV

AP C

OIL

SENSOR

SENSOR

Y

W

W

INCANDESCENT

LIGHT

W

EVAPORATOR HOUSING

POWER BOX

SPLICE

WIRE

NUT

LED DISPLAY

HINGE

SWITCH

DOOR

BLK

FRAME HEATERS

L

3

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

1 2

C L

5

4

H N

6

F

W

W

W

(IF USED)

P

CONTROL

BOX

SWITCH

ENERGY SAVER

GREY

BLUE

CABINE

T AIR

12

WINDING

BLK

BLK

CONDENSER

M

FAN

GROUND

MOTOR PROTECTOR

COMPRESSOR

WINDING

COMPRESSOR

STAR

T

RUN

14

13

CAPACITOR

EVAP FAN

BLK

BRN

WITH BLUE

STRIPES

W

W

W

M

MOTOR

EV

AP C

OIL

SENSOR

SENSOR

Y

W

INCANDESCENT

LIGHT

W

EVAPORATOR HOUSING

START RELAY

POWER BOX

SPLICE

10

11

WIRE

NUT

START

LINE VOLTAGE

115/60/1

SEE NAMEPLATE FOR MAXIMUM

FUSE SIZE

DOOR

SWITCH

ENERGY SAVER

SWITCH

INCANDESCENT

LIGHT

DOOR FRAME

HEATER

HEATER

LED DISPLA

Y

(IF USED

)

EV

AP C

OIL

SENSOR

SENSOR

CABINE

T AIR

1.1,2,3 2.1,2,3 3.1,2,3

RELAY

COMPRESSOR

1

C

CONDENSOR FAN

M

COMPRESSOR

M

FAN RELAY

6

F

CONTROL

CIRCUIT

CONTROL

TEMPERATURE

L

2/3

N

5

M

EVAPORATOR FAN

9294477

L1

N

11"

8

1

2

"

L ENNIS

02-MAY-2011

INITIAL RELEASE

LABEL,WIRING,3DR,REF,

6000XL,ESTAR

RUNNING AND DOORS CLOSED

1) USE COPPER CONDUCTORS ONLY

2) THIS UNIT MUST BE GROUNDED

3) UNIT SHOWN WITH COMPRESSOR

NOTES:

NOTES:

1. STRIP-TAC ADHESIVE BACKING

2. BLACK PRINT ON WHITE PAPER

RED

H

4

RELAY

2/3

RELAY

HEATER

4

H

L ENNIS

17-MAY-2011

2

ADDED L-2/3 DESIGNATION & H-4 FOR HEATER TERMINAL

26-MAY-2011

L ENNIS

BROWN COMPRESSOR WIRE WAS BLACK (ON DIAGRAM ONLY)

3

REVISIONS

LOCATION

DIMENSIONS ARE IN INCHES

TOLERANCES

ALL PARTS TO BE DEBURRED AND EDGES

UNLESS OTHERWISE SPECIFIED

THIRD ANGLE

PROJECTION

The contents of this document are

PROPRIETARY TO THE DELFIELD COMPANY

and are not to be disclosed to others

intended without the written approval

or used for purposes other than

of The Delfield Company.

MATERIAL

PROPRIETARY

BROKEN .010 MAXIMUM.

ANG. ±

.XXX ±

.XX ±

.X ±

.010

.03

1

.1

C

DO NOT SCALE DRAWING

SCALE

SIGNATURE

PURCH:

MFG:

QA:

L ENNIS

CHECKED:

DRAWN:

05-MAY-2011

DATE

SIZE

DESCRIPTION

1

REV

DESCRIPTION

REV.

COVINGTON, TN

ENODIS

3

SHEET

OF

1

1

DWG. NO.

Reach-in Divison

DATE

APPROVED

RECEPTICAL BOX

9294478

11"

8

1

2

"

L ENNIS

02-MAY-2011

INITIAL RELEASE

LABEL,WIRING,3DR,REF,GL DR,

6000XL,ESTAR

CABINE

T AIR

SENSOR

SENSOR

(IF USED

)

LED DISPLA

Y

EV

AP C

OIL

LAMP SWITCH

FLUORESCENT

LAMP

ENERGY SAVER

FLUORESCENT

SWITCH

DOOR FRAME

FLUORESCENT

LAMP BALLAST

HEATER

M

RELAY

COMPRESSOR

1.1,2,3 2.1,2,3 3.1,2,3

1

FAN RELAY

HEATER

C

6

COMPRESSOR

CONDENSOR FAN

M

EVAPORATOR FAN

M

9294478

LINE VOLTAGE

115/60/1

SEE NAMEPLATE FOR MAXIMUM

FUSE SIZE

CONTROL

TEMPERATURE

CONTROL

CIRCUIT

L

2/3

N

5

F

L1

N

LAMP

LAMP

COMPRESSOR

DOOR FRAME

EVAPORATOR FAN

CONDENSOR FAN

LAMP BALLAST

FLUORESCENT

FLUORESCENT

FLUORESCENT

LAMP BALLAST

FLUORESCENT

SENSOR

SENSOR

EV

AP C

OIL

CABINE

T AIR

LAMP SWITCHES

FLUORESCENT

SWITCH

ENERGY SAVER

COMPRESSOR

1.1,2,3 2.1,2,3 3.1,2,3

LED DISPLA

Y

(IF USED

)

RELAY

FAN RELAY

C

1

F

6

CONTROL

CIRCUIT

TEMPERATURE

CONTROL

L

5

N

HEATERS

M

M

M

NOTES:

1. STRIP-TAC ADHESIVE BACKING

2. BLACK PRINT ON WHITE PAPER

1) USE COPPER CONDUCTORS ONLY

2) THIS UNIT MUST BE GROUNDED

NOTES:

3) UNIT SHOWN WITH COMPRESSOR

PLUG

RUNNING AND DOORS CLOSED

ENERGY SAVER

SWITCH

H

4

1.1,2,3 2.1,2,3 3.1,2,3

CONTROL

TEMPERATURE

BLK

L

C

2

1

3

L

GREY

BOX

CONTROL

P

POWER BOX

COMPRESSOR

(IF USED)

LED DISPLAY

W

BLK

WITH BLUE

F

6

N

5

W

W

M

W

W

STRIPES

FAN

CONDENSER

BLK

RUN

WINDING

14

12

11

10

13

STAR

T

WINDING

W

BRN

BLK

W

SPLICE

GROUND

MOTOR PROTECTOR

START

CAPACITOR

COMPRESSOR

START RELAY

NUT

WIRE

EVAPORATOR HOUSING

EVAP FAN

BLUE

SENSOR

SENSOR

EV

AP C

OIL

CABINE

T AIR

Y

M

MOTOR

W

W

BLK

FLUORESCENT LAMP ASSEMBLY

RED

RED

LAMP

SWITCH

FLUORESCENT

BLK

BLK

W

SWITCH

LAMP

FLUORESCENT

BLK

FLUORESCENT LAMP

FLUORESCENT LIGHT

FLUORESCENT LAMP

BALLAST

BLUE

W

FLUORESCENT LIGHT

BALLAST

BLUE

P

BLK

DOOR FRAME HEATERS

BLK

GREY

1.1,2,3 2.1,2,3 3.1,2,3

ENERGY SAVER

P

CONTROL

BLK

BOX

P

FLUORESCENT

SWITCH

LAMP

BLK

W

CABINE

T AIR

EV

AP C

OIL

WINDING

STAR

T

14

DOOR FRAME HEATER

BLK

W

TEMPERATURE

5

3

1 2

CONTROL

4

6

LED DISPLAY

(IF USED)

W

BLK

CONDENSER

M

FAN

WINDINGRUN

N

L

C L

H

F

W

SWITCH

W

BLUE

SENSOR

BRN

BLK

W

BLK

10

12

STRIPES

W

WITH BLUE

SENSOR

W

W

13

MOTOR PROTECTOR

COMPRESSOR

COMPRESSOR

GROUND

START RELAY

CAPACITOR

START

11

POWER BOX

SPLICE

WIRE

NUT

BLUE

EVAPORATOR HOUSING

FLUORESCENT LAMP ASSEMBLY

Y

FLUORESCENT LIGHT

FLUORESCENT LAMP

RED

BALLAST

MOTOR

M

EVAP FAN

ADDED HEATER RELAY TO CONTROL & L-2/3 DESIGNATION

2

17-MAY-2011

L ENNIS

RELAY

H

4

RELAY

HEATER

4

H

2/3

L ENNIS

26-MAY-2011

BROWN COMPRESSOR WIRE WAS BLACK (ON DIAGRAM ONLY)

3