33 of 68

4.4

ENVIRONMENTAL CONDITIONS

The device must be used while being

protected from the weather conditions. The

environments of operation should be well

ventilated and in compliance with current

legislation on hygiene and safety at work.

!

CAUTION

●

Do not approach the machine to

open flames or other similar

sources.

●

Do not use the machine in

places where there is a risk of

explosion and fire: the machine

is not in compliance with the

directive ATEX (ex-2014/34/EU).

●

Exhaust fumes include carbon

monoxide a dangerous and

deadly gas. Never run the

engine indoors or in poorly

ventilated premises.

4.5

STARTING THE WORK CYCLE

After performing the preliminary checks at

startup described in the previous paragraph

(PAR. 4.3) you can start the machine by

following the instructions below:

To start the trowel the operator must:

1. Settle himself into the driver's seat

after having carefully adjusted its

position, placing his feet on the

appropriate foot rest.

2. Make sure that the steering control is

in the neutral position.

3. Close the choke lever (CHOKE).

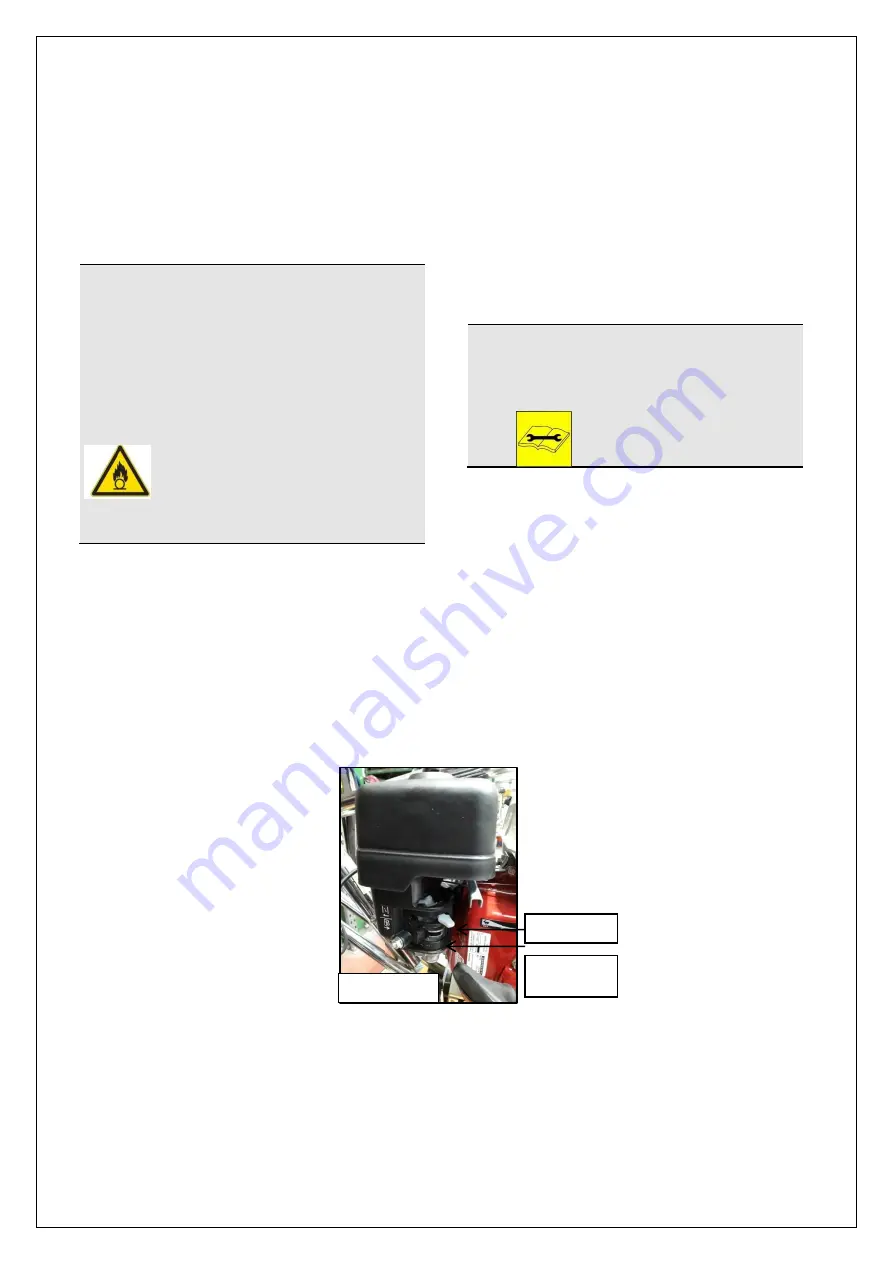

4. Make sure that the petrol tap (Figure

4.9) is in the open position.

5. Move the throttle lever by hand to the

minimum position.

6. Turn the key to start the machine.

7. (For petrol engines only) After start-up

open the choke lever (CHOKE).

IMPORTANT!

For more detailed information on

start-up procedures refer to the

engine’s instruction manual

●

The engine’s start-up occurs at low

revs, the clutch has not yet triggered

and rotors don't turn yet (the clutch

triggers at 1500 rpm). To avoid

skidding which would lead to a high

clutch wear bring the accelerator to a

value of up to 2500 revolutions per

minute.

Figure 4.9

CHOKE

PETROL

TAP

Summary of Contents for MK8-75

Page 19: ...19 of 68...

Page 20: ...20 of 68...

Page 21: ...21 of 68...

Page 22: ...22 of 68...

Page 23: ...23 of 68...

Page 38: ...38 of 68 5 5 LAYOUT OF CONTROLS...

Page 50: ...50 of 68 ATTACHED WIRING DIAGRAM...

Page 51: ...51 of 68 6 5 PARTS LIST...

Page 52: ...52 of 68...

Page 53: ...53 of 68...

Page 54: ...54 of 68...

Page 55: ...55 of 68...

Page 56: ...56 of 68...

Page 57: ...57 of 68...

Page 58: ...58 of 68...

Page 59: ...59 of 68...

Page 60: ...60 of 68...

Page 61: ...61 of 68...

Page 62: ...62 of 68...

Page 63: ...63 of 68...

Page 64: ...64 of 68...

Page 65: ...65 of 68...

Page 66: ...66 of 68...

Page 67: ...67 of 68...