12

Main Power Inlet Connection

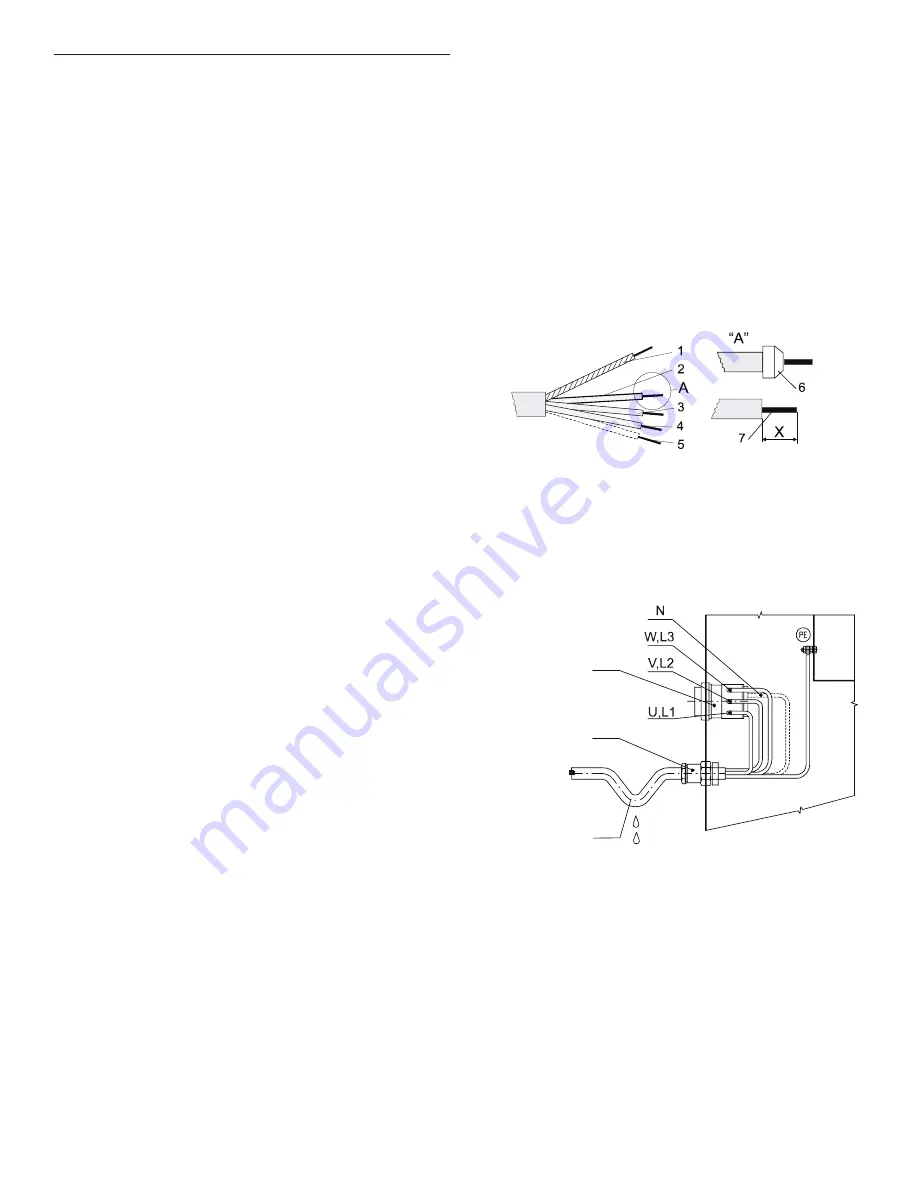

Adaptation of Conductor Ends of Supply Cable

1. Protective conductor

(ground)

2. Phase conductor

3. Phase conductor

4. Phase conductor

5. Neutral conductor

6. Wire-end tube

7. The stripped length

of conductors

Residual Current Device (RCD)

In some locations an RCD is known as an “earth leakage trip,”

“Ground Fault Circuit Interrupter” (GFCI), “Appliance Leakage

Current Interrupter” (ALCI), or “earth (ground) leakage current

breaker.”

Specifications:

■

Tripping current: 100mA (if locally not available use a 30mA trip

current, preferably selective type with small time delay set).

■

Install a maximum of two (2) washers on each RCD (for 30mA,

only one (1) washer)

■

Type B. There are components inside the washer which use

DC-voltages, making a “Type B” RCD necessary.

When locally allowed, an RCD must always be installed. In some

electrical network earthing systems (IT, TN-C,…), an RCD might not

be allowed (see also IEC 60364).

The washer control circuits are mostly supplied by a separating

transformer. Therefore, the RCD may not detect faults in the control

circuits (but the fuse(s) of the separating transformer will).

Supply Protection Device

A supply protection device keeps the washer and wiring from

experiencing overloads and short circuits. As a supply protection

device, you can use either glow-wire fuses or automatic circuit

breakers. See “Technical Specifications” for the rating of the nominal

current and other specifications of the supply protection device.

This table specifies that protection must be the “slow” type, curve D

for circuit breakers. Although not recommended, if you cannot use

a “slow” type, select the protection device with one (1) step higher

nominal current rating to avoid disconnecting during start-up.

Supply Cable

The supply cable is not delivered with the washer.

Specifications:

■

Use conductors with copper cores.

■

Stranded conductors (flexible wiring) are strongly recommended

to avoid conductor breaking due to vibration.

■

The cross section depends on the used supply protection

device. See “Manufacturer’s Recommended Minimal Conductor

Section” in “Electrical Requirements” for the minimal cross

section.

■

The cable should be as short as possible, directly across from

the supply protection device to the washer without branching off.

■

Do not use a plug or extension cords; the washer is intended to

be permanently connected to the electrical network.

Connection:

■

Insert the cable through the hole on the rear panel.

Use a strain relief to secure the supply cable.

■

Strip the conductor ends according to “Adaptation of Conductor

Ends of Supply Cable” illustration on the right.

■

The protective conductor must be longer to ensure it is the last

one disconnected if the cable is pulled out unintentionally.

■

With stranded conductors, it is recommended to use “wire-end

tubes” with an insulated sleeve (6) for L1/U, (L2/V), (L3/W), (N)

conductors. Make sure there cannot be unintentional contact,

since the supply cable stays under voltage even when the main

switch is off.

■

Crimp a ring terminal (eyelet) to the protective conductor

(ground) for good connection to the PE terminal.

■

Connect the supply cable conductors to the terminals

(main switch [1]) marked with L1/U, (L2/V), (L3/W), (N),

and the terminal (copper screw) marked with PE.

See “Main Power Inlet Connection” illustration below.

■

Provide a sag in the cable, in front of the cable strain relief.

This will stop condensed water from entering the washer.

See “Main Power Inlet Connection” illustration below.

1. Main switch

2. Strain relief

3. Sag of inlet cable

1

2

3

Electrical Connection (cont.)