3

INSTALLATION REQUIREMENTS

Tools, Parts, and Equipment

Read and follow the instructions provided with any tools listed

here.

Tools Needed

Washers must be installed by professional installers, who

should have a full compliment of standard SAE and metric hand

tools, and specialized tools as required. Gather the required

tools and parts before starting installation.

Additional Materials

Additional materials may be required for this type of installation

and the customer is responsible for supplying additional

hardware and adapters as necessary.

Parts Supplied

Remove parts bag from washer drum. Check that all parts were

included. The number of parts supplied varies with model.

■

Molded rubber drain hose and band clamp (2 each)

■

Rubber washers for the hoses (4)

■

Water supply hoses (2)

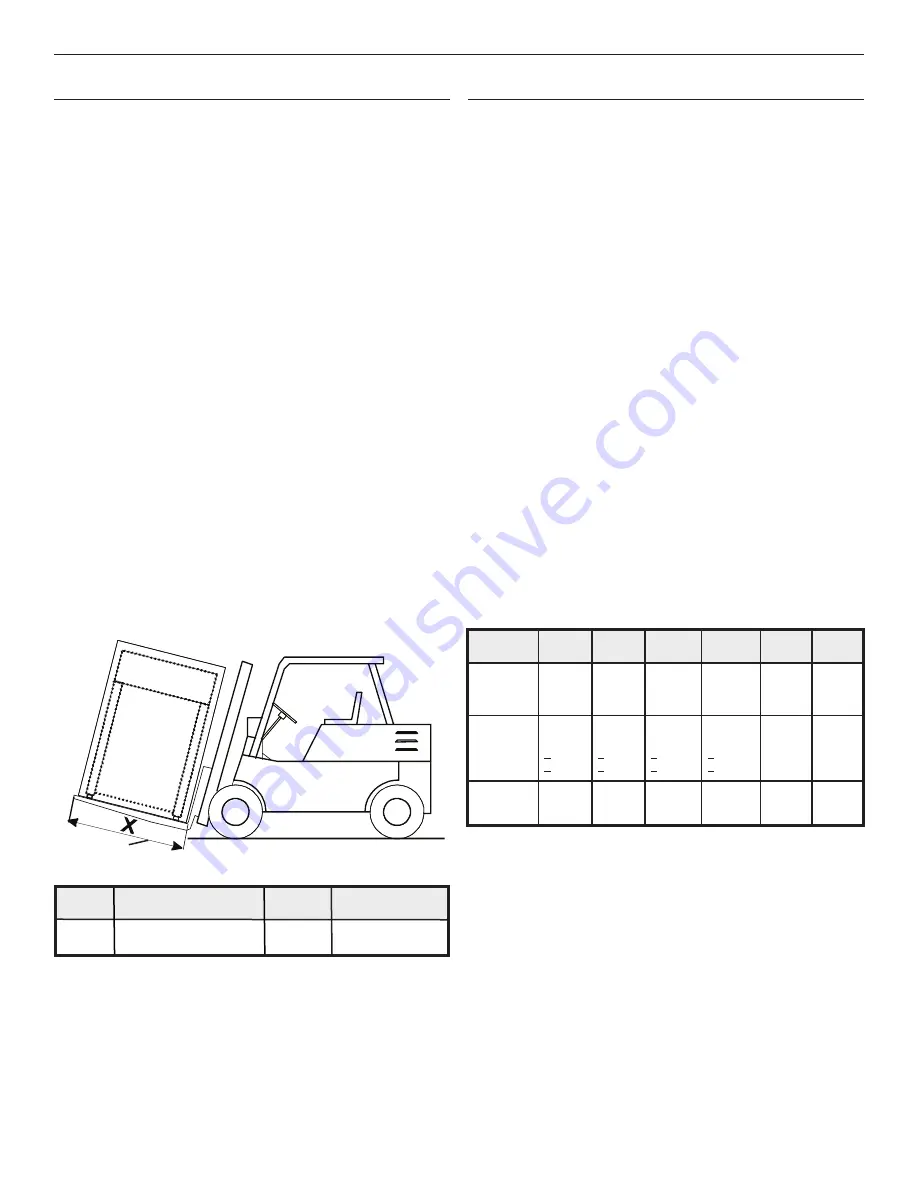

Equipment for Handling, Transport, and Storage

Use a lift truck or a manual skid cart for handling the washer

when it still is in the packaging material.

■

The lift truck forks must be at least 4" (100 mm) longer

than the length of the washer frame.

Location Requirements

Washers must be installed on a level concrete floor on the

ground level of a building. Washers should not be installed on a

floor other than the ground floor, or in a room with a basement

or on a floor with rooms below without approval of a structural

engineer.

Proper installation is your responsibility and must meet all

governing codes and ordinances.

Working Conditions

■

Washers should not be installed within reach of spraying

water.

■

Do not install washer where it will be exposed to weather or

excessive humidity. Do not allow water or condensation to

run over walls or floor under washer. Ambient temperature

for storage or transportation must be between -13 and 131°F

(-25 and 55°C).

Floor

Space requirements for installations are determined by

the number of washers being installed. See “Technical

Specifications” and “Installation Instructions” for more detailed

information.

■

Installation must be on a solid concrete floor or slab capable

of withstanding the weight and vibration produced by the

washer. The maximum slope of the floor is 1° under the

washer. A rough, uncovered concrete surface is preferable

to a smooth or covered surface.

Required Fork Length Chart

X - fork length

59"

71"

79"

1500 mm

1800 mm

2000 mm

80 lbs/100 lbs/125 lbs 180 lbs

230 lbs/275 lbs

(33 kg/40 kg/55 kg)

(80 kg)

(104 kg/125 kg)

Fork

Length

■

If possible, leave the washer in the packaging or on wooden

skid until foundation is prepared for installation. Washer is

attached to skid by four (4) M-16 bolts.

■

See “Moving to Final Location” for more information on

moving washer to its final location.

X

■

A hot water heater set at 158°F (70°C).

■

1" (25 mm) inlet valves for hot and cold water. Determine

water hardness levels. Hard or medium levels may require

a water softener.

■

A dedicated, GFCI-equipped circuit for each washer

(see “Electrical Requirements”).

Water and Electric

■

Washer must be secured with four (4) M16 x 160 mm

anchoring bolts. Install all four anchors before final

installation of the washer. Apply a torque of 210 Nm/

155 ft. lbs.

■

Washer will be firmly secured to the floor and all four (4)

footings must touch the floor.

■

Allow for adequate sanitary sewer drainage, located

behind the washers.

Weight of Washers

Weight on

floor

80 lbs

33 kg

100 lbs

40 kg

125 lbs

55 kg

180 lbs

80 kg

230 lbs

104 kg

275 lbs

125 kg

Maximum

static load

(with linen and

water)

3239 lbs

1469 kg

4083 lbs

1852 kg

4400 lbs

1996 kg

7144 lbs

3241 kg

–

–

Maximum

dynamic

load

(alt.

stress when

extracting)

2855 lbs

1295 kg

+616 lbs

+279 kg

3615 lbs

1640 kg

+661 lbs

+300 kg

3835 lbs

1740 kg

+704 lbs

+319 kg

6176 lbs

2801 kg

+1511 lbs

+685 kg

–

–

Dynamic

load

frequency

14.0 Hz 14.0 Hz 14.0 Hz

12.5 Hz

–

–