Installation and Operational Instructions for

EAS

®

-smartic

®

s

ynchronous clutch Type 48_._ _5._

Sizes 01

– 2

(B.4.17.1.GB)

25/11/2011 TK/NU/SU

Chr. Mayr GmbH + Co. KG

Tel.: +49 8341 804-0

Eichenstraße 1

Fax: +49 8341 804-421

D-87665 Mauerstetten

http://www.mayr.com

Page 7 of 18

Germany

E-Mail:

Design

The EAS

®

-smartic

®

clutch is designed as a mechanical

disengaging overload clutch according to the ball detent

principle.

State of Delivery

The EAS

®

-smartic

®

clutch is manufacturer-assembled ready for

installation.

If no particular torque adjustment is requested customer-side,

the EAS

®

-smartic

®

clutch will always be pre-set to approximately

80 % of the maximum torque.

The reference marking on the adjusting nut (5) or on the locking

ring (21) and the torque specification on the Adjustment Table

(11) directly show the set value.

The hexagon head screw (6/22) is not secured with Loctite on a

pre-set clutch.

Before initial operation of the clutch, please secure the locking

screw (6/22) with Loctite 243.

Please check the state of delivery immediately according to the

Parts List!

mayr

®

will take no responsibility for belated complaints.

Please report transport damage immediately to the deliverer.

Please report incomplete delivery and obvious defects to the

manufacturer.

Function

Function in Normal Operation

The EAS

®

-smartic

®

clutch Type 481. transmits the torque from

the input shaft onto the output element, which can be mounted

onto the ball bearing supported pressure flange (3) of the clutch.

The torque is transmitted backlash-free over the entire service

lifetime of the clutch.

The EAS

®

-smartic

®

Types 484. and 486. connect two shafts and

compensate for shaft misalignments.

Function on Overload

If the set limit torque is exceeded, the clutch disengages. The

torque drops immediately.

The residual torque is approx. 5 - 20 % of the set torque (at

approx. 1500 rpm).

Therefore, the EAS

®

-smartic

®

clutch is not load-holding.

An installed limit switch (Item 18 / not included in delivery)

registers the disengagement movement and switches off the

drive.

Once the cause of malfunction has been removed, the clutch is

automatically ready for operation after having reached the

synchronous position:

Re-engagement after 360°.

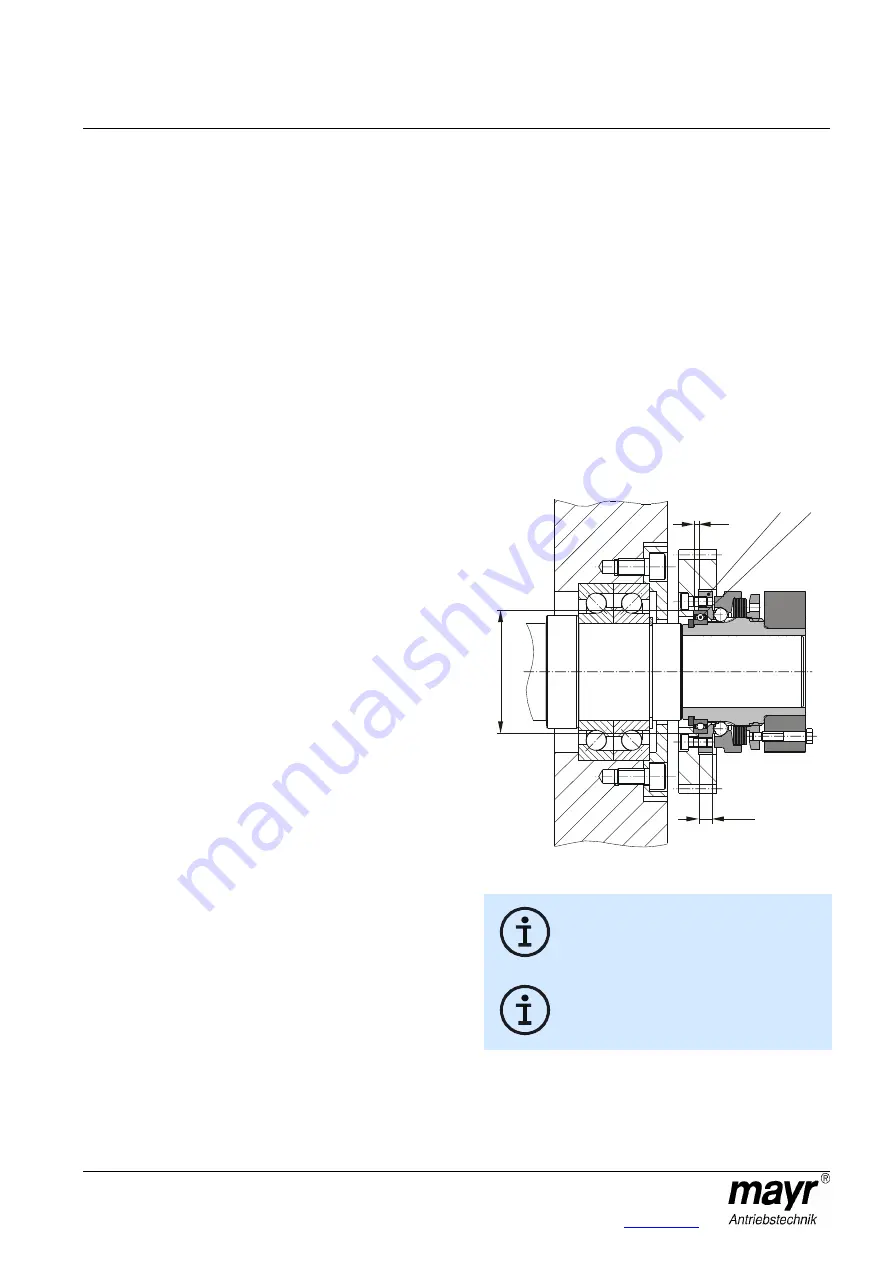

Installation of the Output Elements (Fig. 4)

The output elements are centred on the deep groove ball

bearing (7) (tolerance H7/h5) and screwed together with the

pressure flange (3).

Please use

screws with a strength class of 12.9

with the

corresponding tightening torques acc. Table 1 (tightening

torque Item 14) for screwing onto the pressure flange (3).

The output element must be made of a material with a

minimum tensile strength of approx. 600 N/mm

2

.

Please contact the manufacturers if this is not the case.

If the resulting radial force from the output element is anywhere

near the centre of the ball bearing, an additional bearing for the

output element is not necessary.

No appreciable axial forces should be transmitted from the

output element onto the clutch pressure flange (3).

Output elements with a very small diameter can be screwed

together with the clutch pressure flange (3) via a customer-side

intermediate flange.

Ball bearings, needle bearings or bearing bushings are suitable

as bearings for the output element, depending on the

installation situation and the installation space.

Please make sure that the output element bearing is designed

as a location bearing (Fig. 4).

Fig. 4

The radial forces, axial forces or transverse

force torques, which are introduced into the

clutch bearing must not exceed the permitted

values acc. Table 1.

Please observe the connection dimensions "a"

and "e" for the output elements as well as the

maximum permitted screw-in depth "b

max.

" in

the pressure flange (3); see Fig. 4 and Table 1

on page 5.

7

3

a

Ø

e

b

max.