Installation and Operational Instructions for

EAS

®

-smartic

®

s

ynchronous clutch Type 48_._ _5._

Sizes 01

– 2

(B.4.17.1.GB)

25/11/2011 TK/NU/SU

Chr. Mayr GmbH + Co. KG

Tel.: +49 8341 804-0

Eichenstraße 1

Fax: +49 8341 804-421

D-87665 Mauerstetten

http://www.mayr.com

Page 12 of 18

Germany

E-Mail:

Torque Adjustment

In order to guarantee low-wear clutch operation, it is essential to

adjust the torque to a sufficiently high service factor (overload

torque to operating torque). Our experience has shown that an

adjustment factor of 1,3 to 3 gives good results.

For very high load changes, high accelerations and uneven

operation, please set the adjustment factor higher.

The respective torque adjustment range is printed on the

Adjustment Table (11). Torque adjustment is carried out by

turning the adjusting nut (5/20). The installed cup springs (10)

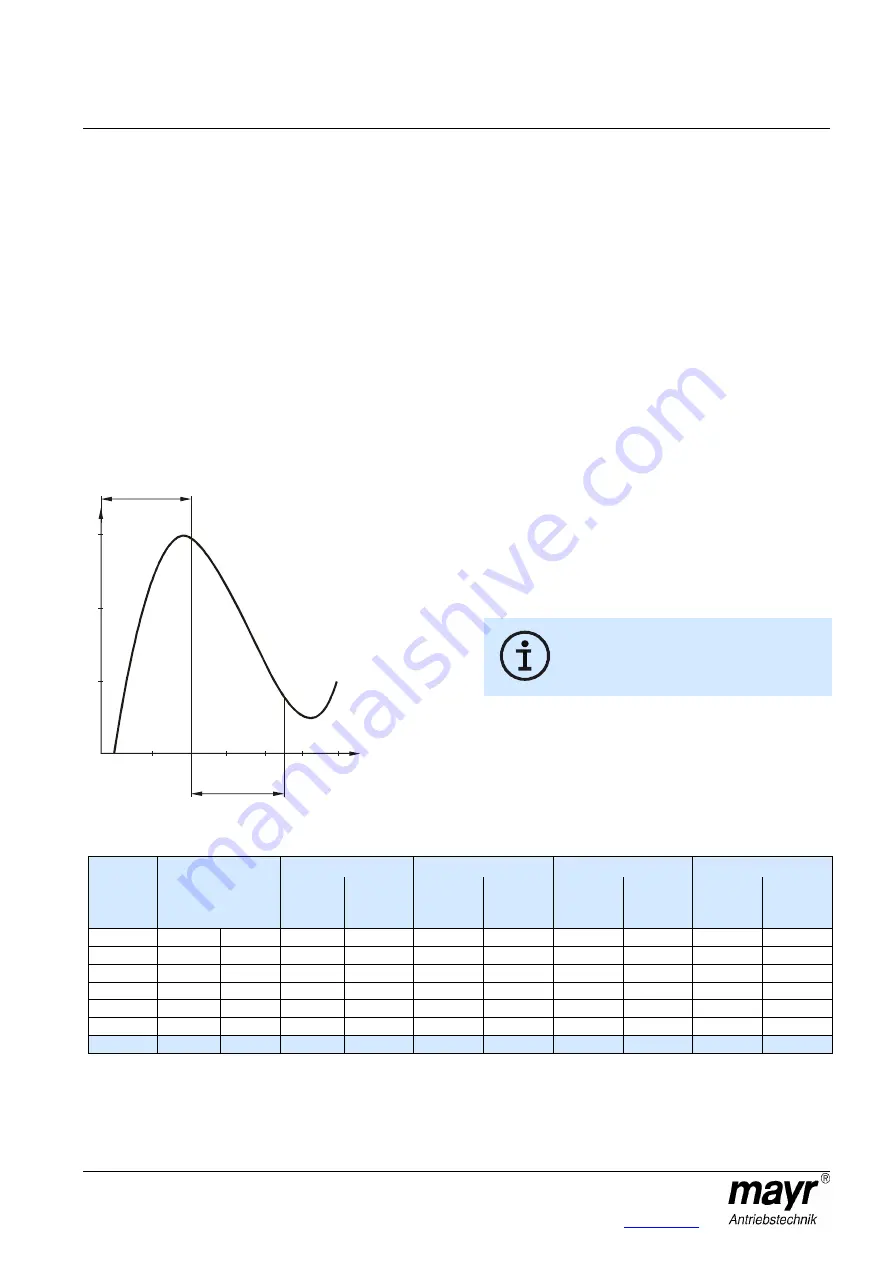

are operated in the negative range of the characteristic curve

(see Fig. 14). This means that tightening the adjusting nut

(5/20) causes the spring force to decrease, and loosening the

adjusting nut (5/20) causes the spring force to increase.

If no torque is specified on order, the clutch is pre-set to

approx. 80 % of the maximum torque. The reference marking

and the torque specification show the set value directly.

If no changes to the pre-set clutch torque are required

customer-side, the hexagon head screws (6/22) must

nevertheless be screwed out, painted with Loctite 243 and

screwed back in again by the customer.

Fig. 14

Cup Spring Layering

Correct cup spring layering is a prerequisite for problem-free

clutch function and torque adjustment.

On all Sizes, 7 torque ranges (see Table 3) are possible.

Changing the Torque

On clamping ring hub designs

Type 48_._35._

and Type 48_._45._

In order to adjust the torque to a different value, simply

1. loosen and unscrew the hexagon head screw (6),

2. adjust the adjusting nut (5) using a hook wrench until the

reference marking shows the required torque value,

3. if necessary, correct the adjusting nut (5) position slightly

until the marking notches between the clamping ring hub

(1/1.1) and the adjusting nut (5) align, and

4. paint the hexagon head screw (6) with Loctite 243 before

screwing it back in again.

On key design Type 48_._25._

In order to adjust the torque to a different value, simply

1. loosen and unscrew the hexagon head screw (22),

2. adjust the adjusting nut (20) using a hook wrench until the

reference marking shows the required torque value,

3. if necessary, correct the adjusting nut (20) position slightly

until the marking notches between the locking ring (21) and

the adjusting nut (20) align, and

4. paint the hexagon head screw (22) with Loctite 243 before

screwing it back in again.

Adjusting the adjusting nut (5/20) or distorting

the cup springs (10) outside of the cup spring

characteristic curve (see Fig. 14) stops the

clutch functioning.

Table 3: Cup Spring Layering and Torque Ranges

Size 01

Size 0

Size 1

Size 2

Type

Cup spring

layering

3)

[Nm]

Graduation

lines for

M = 80 %

[Nm]

Graduation

lines for

M = 80 %

[Nm]

Graduation

lines for

M = 80 %

[Nm]

Graduation

lines for

M = 80 %

48_.2_5._

1x1 times 1 \ /////// 7

2,7

– 5

19

5

– 10

21

10

– 20

16

20

– 40

25

48_.3_5._

1x2 times 2 \\ ////// 6

5

– 10

19

10

– 20

22

20

– 40

17

40

– 80

26

48_.4_5._

1x3 times 3 \\\ ///// 5

8

– 15

20

15

– 30

23

30

– 60

19

60

– 120

28

48_.5_5._

1x4 times 4 \\\\ //// 4

11

– 20

20

20

– 40

23

40

– 80

19

80

– 160

28

48_.6_5._

1x6 times 6 \\\\\\ // 2

18

– 33

20

35

– 65

24

70

– 125

20

140

– 250

30

48_.7_5._

1x8 times 8 \\\\\\\\ 0

32

– 40

21

60

– 80

27

120

– 160

25

240

– 320

32

48_.8_5._

4)

1x8 times 8 \\\\\\\\ 0

35

– 60

24

70

– 120

31

150

– 240

25

300

– 500

35

3)

Example:

On Type 481.425.0, the cup spring layering is 1x3 times, which means that three cup springs are engaged thrust washer-side

and five cup springs are not engaged (adjusting nut-side) => 3 \\\ ///// 5.

4)

Types 48_.8_5._ require a special pressure flange as well as a special thrust washer.

Path to

operating range

F

o

rc

e

F

Graph of

spring characteristic

curve

Operating

range

Spring path S