15

tools etc in accordance with these instruc-

tions. Take the working conditions and the

tasks to be completed into account.The use of

electrical tools for tasks other than the one they

are intended for can lead to dangerous situations.

1.3 Service

• Only have your electrical tools repaired by

qualified specialists and with original replacement

parts.This ensures that the safety of the electrical

tool is maintained.

• Before conducting any maintenance, make sure

the device is unplugged (disconnect the

power supply) and wait until the blade shaft is

at a complete standstill. Allow the device to cool

down before doing anything.

• Only those maintenance and fault elimination

tasks described here, may be carried out. Any

other tasks must be completed by a specialist.

• Check all screws regularly to ensure that they sit

tight.

• Conversions, independent modifications and the

use of non-approved parts are not permitted.

• Only use original replacement parts. Only these

replacement parts are designed and suitable

for the device. Other replacement parts will not

only lead to an invalidation of the guarantee,

they may also endanger you and your

environment. Always store the device in a dry

location.

• If the machine is switched off for the purpose of

maintenance, storage or to replace an acces-

sory, ensure that the plug has been pulled from

the socket. Ensure that all of the moving parts

have come to a standstill and, if there is a key,

remove it. Allow the machine to cool down

before carrying out maintenance, adjustment

work etc.

• Always allow the machine to cool down before

storing.

• Never transport the unit with the engine

running. Protect the device from becoming

damaged during transportation.

2. PREPARATION

1. Before starting the machine, look into the

feeding chamber to make certain, that it is empry.

2. Keep proper balance and footing at all times.

Do not over reach. Never stand at a higher level

than the base of the machine, when feeding

material into it.

3. Always stand clear of the discharge zone when

operating this machine.

4. When feeding material into the machine be

extremely careful that pieces of metal, rocks,

bottles,cans or other foreign objects are not

included.

5. If the cutting machanism strikes any foreign

objects or if the machine should start making any

unusual noise or vibration, shut off the power

source and allow the machine to stop, dicconnect

the plug(electric unti disconnect from supply)and

take the following steps :

a) Inspect for damage.

b) Check for and tighten any loose parts

c) Have any damaged parts replaced or repaired

with parts having equivalent specifications.

6. Do not allow processed material to build up

in the discharge zone ; this may prevent proper

discharge anc can result kickback of material

through the feed intake opening.

7. Keep all guards and deflectors in place and in

good working condition.

8. Do not transport this machine while the power

source is running.

9. Shut off the power source and disconnect

the plug(electric unti disconnect from supply)

whenever you leave the work area.

10. Do not tilt the machine while the power

source in running.

11. Motor should be kept clean of debris and

other accumulations.

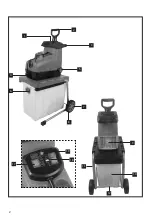

Description of symbols

Read the uesr manual fefore using the

machine.