Mass Combi Ultra, Mass Combi Pro

– Installation Manual Multiple Units

Parallel configuration with DIP switches

11

4 PARALLEL CONFIGURATION WITH DIP SWITHES

Two units can be set in parallel with DIP-switches. This can be two identical MCU or MCP units. Provided that they use the

same DC voltage, this can also be one MCU and one MCP.

4.1

Materials needed

Description

Quantity

Two units

2

Temperature sensor with cable and plug (included)

MasterBus Terminator (included but not always needed)

MasterBus cables between units (product code e.g. 3 meter: 77040300)

1

Sync cables to interconnect all units (product code e.g. 3 meter: 6502000030) 1

DC + cable with fuse

2

DC

– cable

2

AC cable to connect the AC input of the unit to an external power source

2

AC cable to connect the external load to

OUTPUT

1

2

AC cable to connect the external load to

OUTPUT

2

2

4.2

Preparation

-

Make sure that all power sources (AC and DC) are switched off.

4.3

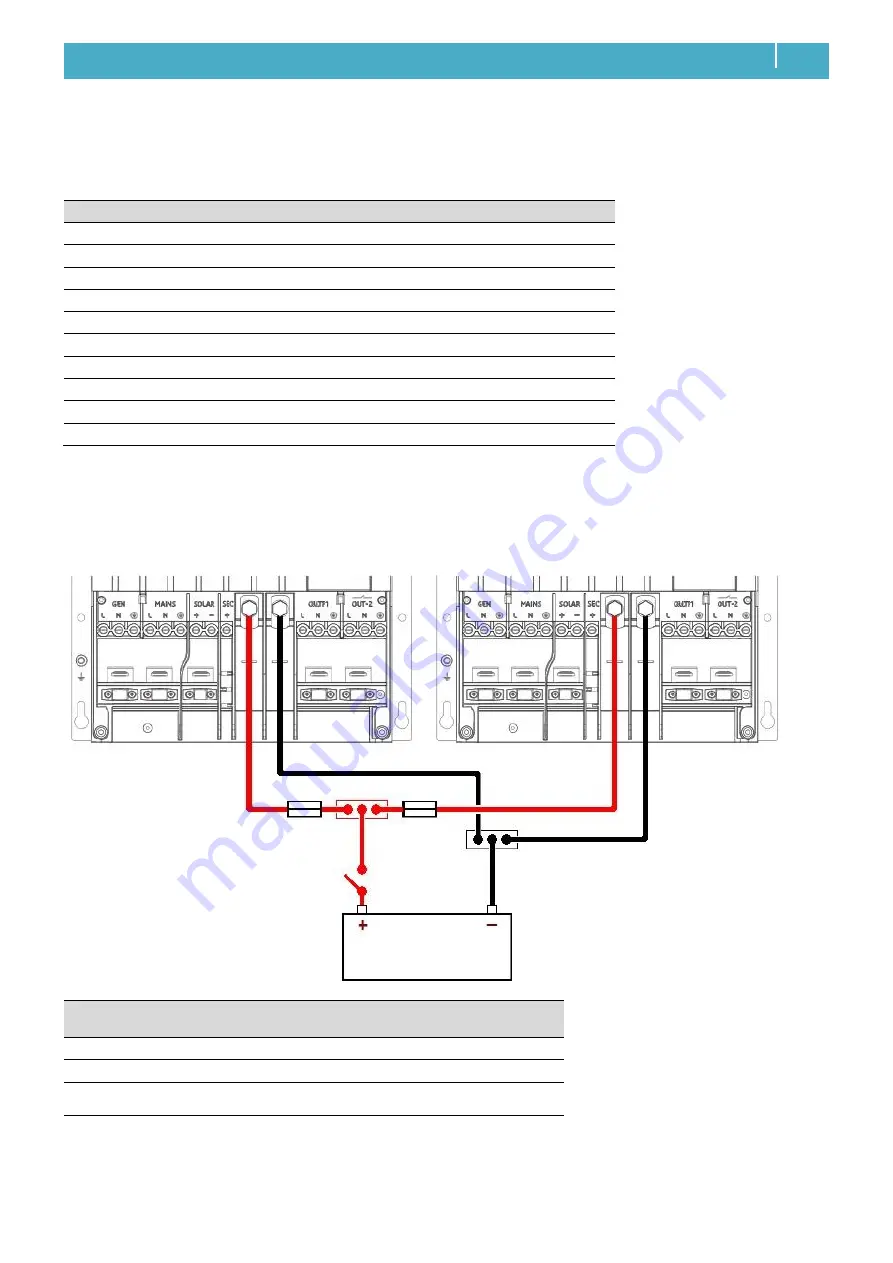

DC wiring of parallel units

Note:

Always use the same length positive and negative cables! Be aware that to keep the drawings in this chapter clear and

easy to read, the cable lengths have not been drawn in proportion to each other.

Power system

DC cable cross

section

Inline fuse

Recommended

battery bank

Indicated cable sizes are for cables from

unit to busbar and shorter than 3m. Cables

from busbar to battery bank should be

twice the diameter. When cables are

longer than 3m, the size should be

increased to compensate for cable losses.

12V

95 mm

2

350 A

800 Ah

24V

50 mm

2

175 A

400 Ah

48V

35 mm

2

80 A

200 Ah

FUSE

FUSE

BUSBAR

BATTERY

SWITCH

BATTERY BANK