7

WARNING:

Know your cordless impact

driver. Do not plug in the charger or install

the battery in the tool until you have read

and understand this Instruction Manual.

Learn the tool’s applications and limitations,

as well as the specific potential hazards

related to this tool.

Following this rule will

reduce the risk of electric shock, fire, or serious

injury.

Always wear eye protection. Any

power tool can throw foreign

objects into your eyes and cause

permanent eye damage.

ALWAYS wear safety goggles (not glasses) that

comply with ANSI safety standard Z87.1.

Everyday glasses have only impact resistant

lenses. They ARE NOT safety glasses.

WARNING:

Glasses or goggles not in

compliance with ANSI Z87.1 could cause

serious injury when they break.

Always use hearing protection when operating

the impact driver.

Use only impact sockets and accessories that

are designed for use with an impact driver. Do

not use chrome plated sockets and accessories.

Chrome plated sockets and accessories are

designed for hand use only and MUST NOT be

used with an impact driver. They may shatter

and possibly cause serious injury.

Before each use, check the impact sockets and

accessories for excessive wear or cracks. Worn

or damaged sockets or accessories may shatter

and possibly cause serious injury. Worn

accessories may allow the socket to come off

during operation of the impact driver.

After installing any accessory in the hex drive,

pull outward on the accessory to ensure it is

properly installed and cannot be pulled out of

the hex drive.

Never use the impact driver as a torque wrench.

Always use a torque wrench to adjust the

fastener to the specified torque.

Keep the impact driver handle and body clean

and free of oil and grease. Always use a clean

dry cloth when cleaning. Do not use solvents,

brake fluid, gasoline or other petroleum products

to clean the tool. They will damage the tool.

Do not wear neckties or loose clothing.

When wearing gloves, they must be tight fitting

and slip resistant type. Leather gloves offer the

best protection.

Always use two hands when operating the

impact driver. Use one hand on the handle and

the other on the front of the tool body.

Never place your hand so it is touching the

socket or accessory when the tool is turned ON.

Your hand could be seriously injured.

Always remove the battery from the tool before

installing or removing any socket or accessory.

Be ready for components to shift when removing

any fastener. The speed of the fastener removal

could cause unexpected shifting of the

components.

SPECIFIC SAFETY RULES

!

!

Summary of Contents for 054-3167-8

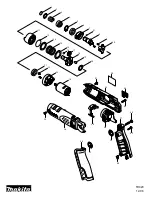

Page 19: ...19 EXPLODED VIEW...