Page 14

Page 13

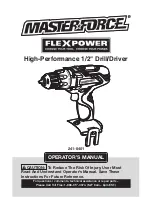

OPERATION

1. Check the direction-of-rotation selector

for the correct setting (forward or

reverse).

2. Use a vise or clamps to secure the

material to be drilled to keep it from

turning as the drill bit rotates.

3. Hold the cordless drill/driver firmly, and

place the bit at the point to be drilled.

4. Depress the trigger switch to start the

cordless drill.

5. Move the drill bit into the workpiece,

applying only enough pressure to keep

the bit cutting.

6. Do not force the cordless drill/driver or

apply sideways pressure to elongate a

hole. Allow the tool to do the work.

7. When drilling hard, smooth surfaces,

use a center punch to mark the desired

location of the hole. This will prevent the

drill bit from slipping off-center when

the hole is started.

8. When drilling metal, use light oil on the

drill bit to prevent it from overheating.

The oil will prolong the life of the bit and

will increase the drilling efficiency.

9. If the bit jams in the workpiece or if

the drill/driver stalls, stop the tool

immediately. Reverse the direction of

rotation and gently squeeze the trigger

to remove the bit from the workpiece.

Investigate and correct the cause of

jamming before resuming work.

WARNING:

Be prepared for binding

when the bit breaks through the workpiece,

because the drill/driver has a tendency

to grab and kick opposite to the direction

of rotation, which could cause a loss of

control. If the operator is not prepared, this

loss of control could result in serious injury.

REMOVING A bIT (FIG. 11b)

1. Lock the trigger switch by placing the

direction-of rotation selector in the OFF

(center) position.

2. Open the jaws of the chuck (rotate in the

“OPEN” direction.)

3. Remove the drill bit.

GENERAL DRILLING (FIG. 12)

WARNING:

Always wear safety

goggles or safety glasses with side shields

during power tool operation or when

blowing dust. If the operation is dusty, also

wear a dust mask.

17 19 21 23

FIG.11b

17 19 21 23

FIG.12

OPERATION

DRILLING MODE OPERATION

For drilling in wood, use twist bits, spade

bits, power auger bits or hole saws.

1. When drilling “through” holes, place a

block of wood behind the workpiece to

prevent ragged or splintered edges on

the back side of the hole.

2. Select the desired speed to match the

planned operation.

3. Begin drilling at a very low speed to

prevent the bit from slipping off the

starting point, and then increase the

speed as the drill bit bites into the

material.

4. If the drill/driver stalls, it is usually

because it is being overloaded. Release

the trigger switch immediately, remove

the drill bit from the work, and determine

the cause of stalling.

5. Keep the motor running when pulling

the bit back out of the drilled hole. This

will prevent jamming.

For drilling in metal, use high-speed steel

twist drill bits.

1. Use light oil on the drill bit to keep it

from overheating; the oil will prolong the

life of the bit and increase the drilling

action.

2. When drilling a large hole, first use a

smaller bit to drill a small pilot hole to

prevent the larger bit from slipping.

3. Select the desired speed to match the

planned operation.

4. Begin drilling at a very low speed to

prevent the bit from slipping off the

starting point. Maintain a speed and

pressure that allows cutting without

overheating the bit.

5. If the drill/driver stalls, it is usually

because it is being overloaded. Release

the trigger switch immediately, remove

the drill bit from the work, and determine

the cause of stalling.

6. Keep the motor running when pulling

the bit back out of the drilled hole. This

will prevent jamming.

SCREWDRIVER OPERATION

1. Select the desired speed/torque range

to match the planned operation.

2. Attach the desired fastener accessory

into the chuck.

3. Make a few practice runs in a scrap

piece before working.

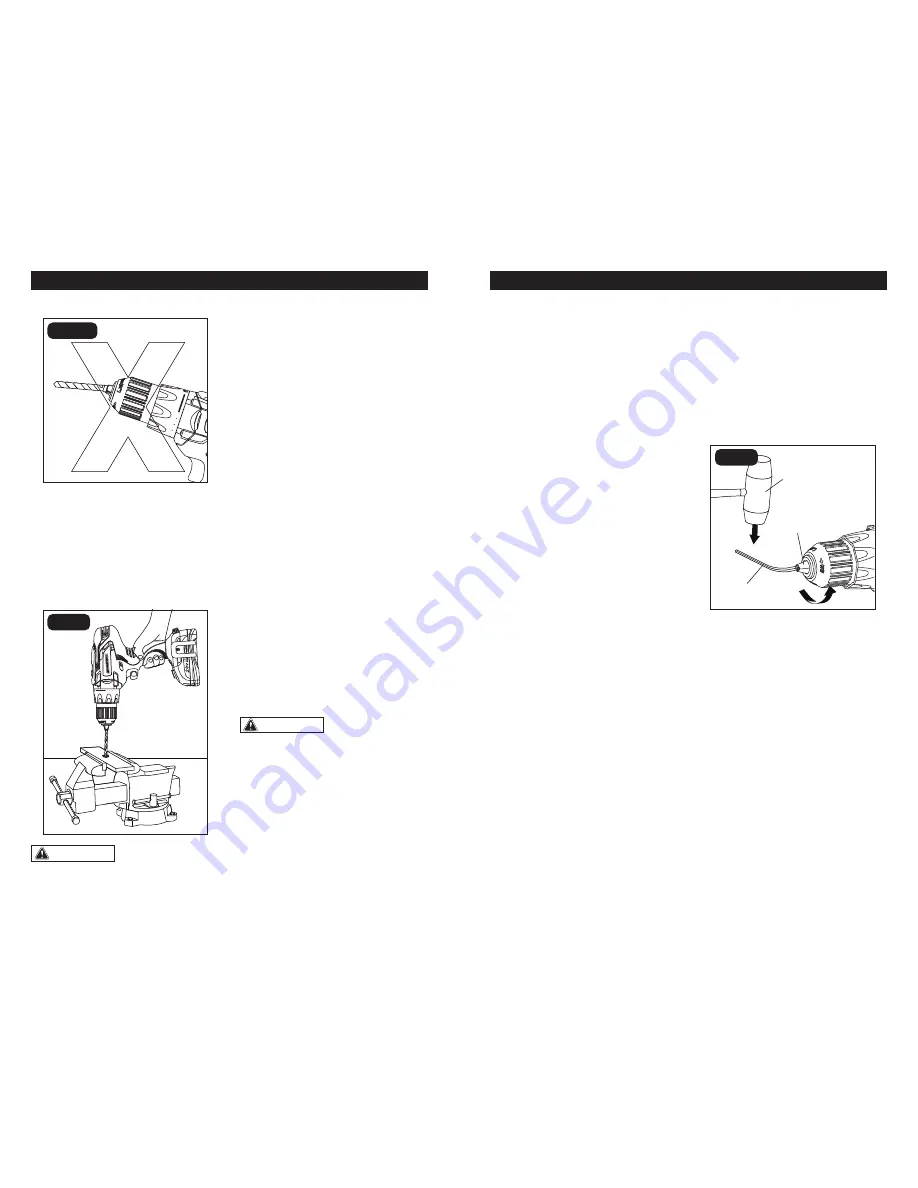

CHUCk REMOVAL (FIG. 13)

The chuck can be removed and replaced

with a new one.

1. Remove the battery.

2. Lock the trigger switch by placing the

direction-of-rotation selector in the

center position.

3. Open the chuck jaws. Using a

screwdriver, remove the chuck screw by

turning it clockwise,

4. Insert a 5/16-in. or larger hex key into

the chuck of the drill/driver and tighten

the chuck jaws securely.

5. Tap the hex key sharply with a mallet in

a counter-clockwise direction. This will

loosen the chuck for easy removal.

6. Attach a new chuck to the spindle and

tighten the chuck screw.

FIG.13

Hex wrench

Chuck jaws

Mallet