Page 16

Page 15

MAINTENANCE

WARNING:

To avoid serious

personal injury, always disconnect

the plug from the power source when

cleaning or performing any maintenance.

Contact a qualified service technician for

ALL repairs.

WARNING:

Avoid using solvents

when cleaning plastic parts. Most plastics

are susceptible to damage from various

types of commercial solvents and may be

damaged by their use. Use clean cloths to

remove dirt, dust, oil, grease, etc.

WARNING:

If the supply cord

is damaged, it must be replaced by a

specially prepared cord available through

the service organization.

WARNING:

When servicing, use

only identical replacement parts. Use

of any other parts may create a hazard

or cause product damage. To ensure

safety and reliability, all repairs should

be performed by a qualified service

technician.

Periodic maintenance of your shear allows

for long life and trouble-free operation.

A cleaning, lubrication and maintenance

schedule should be maintained.

As a common-sense and preventive

maintenance practice, follow these

recommended steps:

1. Inspect the shear and accessories;

check them for wear or damage.

2. Keep the ventilation slots clean to

prevent overheating of the motor.

3. The shear maybe cleaned most

effectively with compressed dry air.

Always wear safety goggles when

cleaning tools with compressed air.

4. Use a soft, clean, damp cloth to wipe

the tool housing. A mild detergent can

be used but nothing like alcohol, petrol

or other cleaning agent. Never use

caustic agents to clean plastic parts.

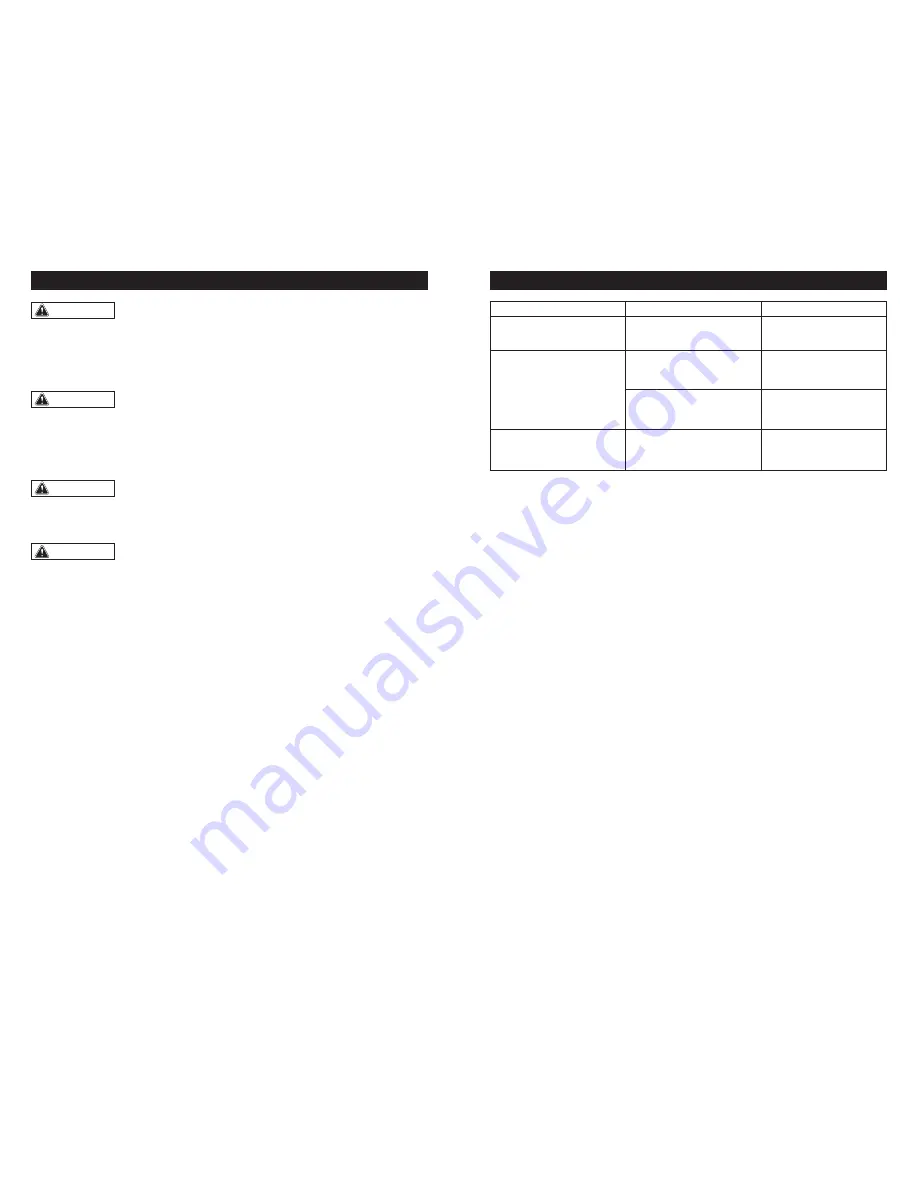

TROUbLESHOOTING

PRObLEM

CAUSE

SOLUTION

The drill/driver does not work Battery is depleted

Charge the battery

Bit cannot be installed

Chuck is not opened

Open the chuck

Bit does not fit the chuck

Use suitable bit

Motor overheating

Be sure cooling vents are

free from dust and obstacles

Clean, clear vents. Do not

cover with hand during

operation