DiskFlo Control Valves

3

Quick Check:

Before starting, the control valve should be checked as per the

these steps given below :

Full stroke needs to be checked by making the appropriate

instrument signal change. The disc position indicator plate

mounted which is mounted on the transfer case should be

observed for this. The change in the position of the disc must

be in a rotary fashion and smooth.

All the air connections should be checked for leaks and in

case of leaking lines, tighten or replace.

The packing nuts are to be tightened evenly by little over

finger-tight force.

CAUTION :

The packing should not be over tightened. The

over tightening may cause excessive packing wear and

high shaft friction, that can adversely affect the rotation of

the shaft.

The packing nuts need to be inspected after some time of

operation of the valve to make sure that they are just over

finger-tight and not more. Readjustment should be done if

needed. The packing nuts should be tightened just enough to

stop leakage in case of the leaking in the packing box.

For observing the valve failure mode when air failure occurs,

the valve needs to be positioned to mid-stroke and the air

supply needs to be shut off or the instrument signal needs to

be disconnected. On observation of the indicator plate, the

disc should either fail open or closed. Please refer "Reversing

the Actuator" section in the appropriate Actuator Maintenance

Instructions if incorrect.

PREVENTIVE MAINTENANCE

The preventive maintenance steps presented below need to be

followed and at least once every six months, proper operation

should be checked. These steps are easy and can be performed

while the valve is in line and, in some cases, without interrupting

service. Refer to the "Dis-assembly and Reassembly" section if an

internal problem is suspected.

Check for any signs of gasket leakage through body and line

flanges. Tightening of flange bolting should be done if

needed.

Pay attention to any corrosive fumes or process drippings that

are likely to cause damage to the valve.

For any areas of severe oxidation, cleaning of the valve needs

to be done, followed by painting.

For proper tightness, inspect the packing box bolting. The

tightness of the Packing nuts should be slightly over finger-

tight. To prevent stem leakage, tighten as necessary.

CAUTION : Never overtighten the packing.

In case of valve supplied with a lubricator, lubricant supply

needs to be checked and adding of lubricant if necessary

should be done.

When possible, stroke valve and verify functioning for

smooth, full-stroke operation by seeing the disc position

indicator plate that is on the transfer case. An internal valve

problem is indicated by unsteady movement of the disc (In

case when Grafoil packing is used, jerky motion is normal).

By observing the gauges and the disc position indicator plate,

check the positioner calibration. Ensuring calibration of the

positioner to the correct range is important.

Ensure that the positioner linkage and internal actuator parts

are securely fastened by removing transfer case cover plate.

Using a soap solution, check for air leaks through actuator

stem seal.

CAUTION :

Without the cover plate installed, air should

not be applied to the actuator because there is a possibility

of the unsup-ported shaft getting damaged.

Ensure secure fastening of all accessories, brackets and

bolting.

For correct fail-safe action, remove air supply and observe

stroke plate if possible.

To check for air leaks through the O-rings, spray soap

solution around the cylinder retaining ring and the adjusting

screw.

The ex-posed portion of the shaft should be free from dirt or

other foreign material.

In the air filter, check and replace cartridge if needed.

DISASSEMBLY AND REASSEMBLY

Removal of Valve from Line

When disassembly is required on a suspected internal

problem with the valve, the valve needs to be removed from

the line. The procedure for the same is as follows:

WARNING :

Bring the line to atmospheric pres-sure and

drain all process fluids. In case of presence of caustic or

hazardous materials, decontaminate the valve. Possibility

of injur is eliminated by decontamination.

1.

2.

3.

4.

1.

2.

3.

4.

5.

7.

6.

8.

9.

10.

11.

12.

13.

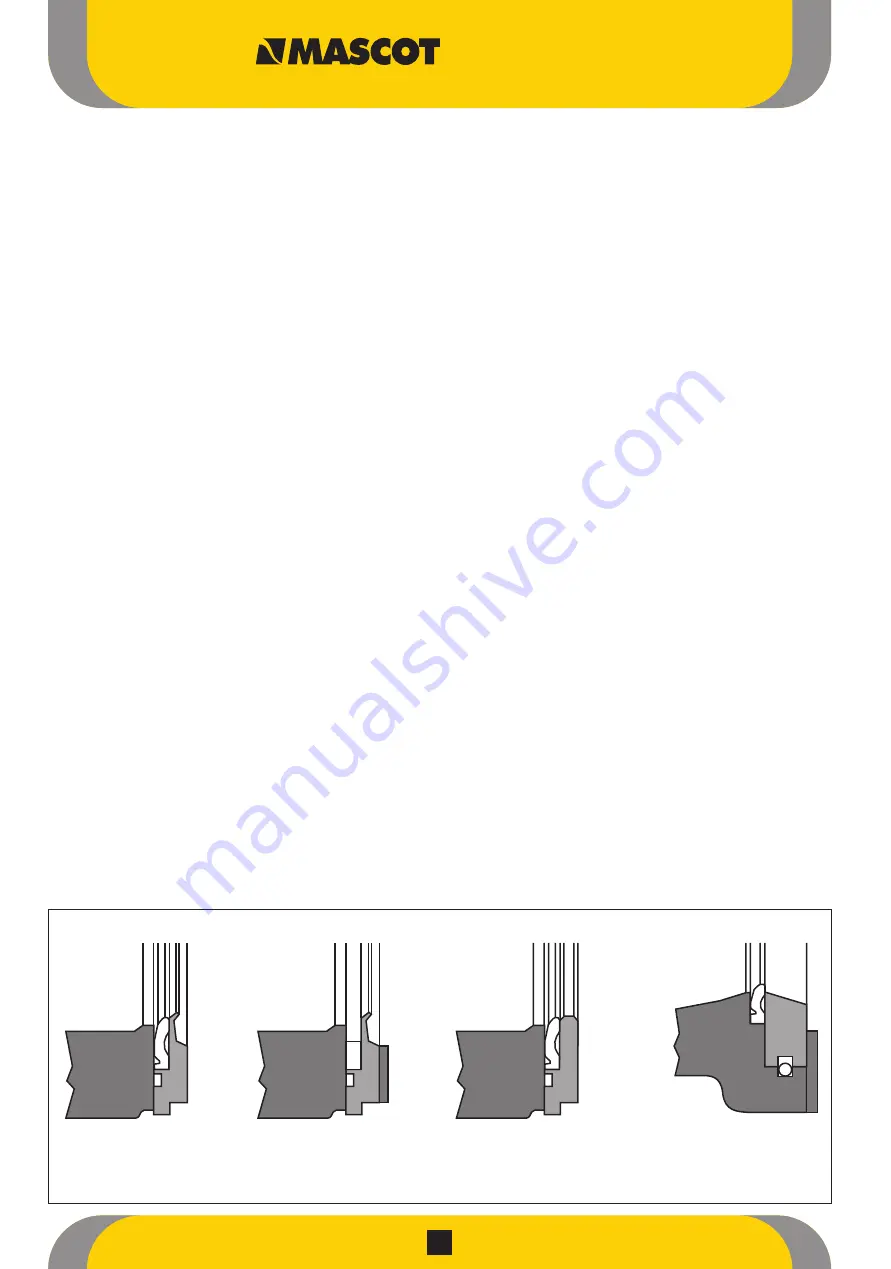

Figure 1: Seat Retainer Configurations

A Dual Seat

B Metal Seat

C Soft Seat

D Seat Insert /

Snap-ring