2

GENERAL INFORMATION

The guidelines below will help you in un-packing, installing and

doing maintenance of DiskFlo rotary valves. It is advised that the

relevant personnel should review this bulletin thoroughly before

proceeding to install, operate, or perform maintenance on the

DiskFlo rotary valves. Instructions for maintenance of

accessories, fail-safe systems, etc. are given separately.

Installing, maintaining, troubleshooting, calibrating, and

operating Mascot actuators or positioners is not covered in this

publication. You need to refer the right Mascot Installation,

Operation, Maintenance guidelines when the information is

needed.

It is strongly advised to stick to the WARNING and CAUTION

notes for preventing any possible injury or damage to personnel

or valve parts. Modifying, substituting nonfactory parts, or using

maintenance procedures other than mentioned in this manual

not only will adversely affect performance and can be dangerous

to the operators and equipment but also will void the warranties.

WARNING :

Please follow the standard industry safety practices

when working on every process control product. Use of personal

protection and proper lifting is advised.

Note :

The onus of selecting the right fastener material is on the

customer. The supplier cannot know about the valve service

conditions or environment that may be existing. The standard

body bolting material of Mascot's is B7/2H. There is an option

for B8 (stainless steel) when temperatures are above 800 °F and

with alloy body or stainless steel valves. The onus of considering

material's re-sistance to stress corrosion cracking in addition to

general corrosion lies on the customer. Periodic inspection and

maintenance is required, as with all the mechanical equipments.

In case more details are needed about fastener materials, please

contact the local Mascot factory, office or representative.

Unpacking :

During the unpacking of valve, the packing list received with

the materials needs to be checked. Detailed description of the

valve and accessories are included in the lists in each

shipping container.

Proper attention is to be paid during the positioning of lifting

straps. This will avoid damage to tubing and mounted

accessories while lifting the valve from the shipping container.

The actuator lifting ring is advised to be used for lifting

Valves up through 14-inch. Use lifting straps or hook through

the yoke legs and outer end of the body for lifting the larger

valves.

The shipper should be contacted immediately in case of an

unfortunate event of damage caused due to negligence while

shipping.

Mascot representative is always at your service in case any

problems.

Installation :

The first step is to do basic cleaning for the line of dirt, scale, welding

chips, and other possible foreign material. The surfaces of gasket

should be cleaned thoroughly thus ensuring that the joints are leak-

proof

The direction of the flow should be checked for ensuring that the

installation of valve is right. In case of Fail-closed valves,installation

should be done only on gas service with the shaft upstream. In case

of liquid service valves, installation is preferred with the shaft

downstream, irrespective of the air failure action. Under certain flow

conditions, however, the valve can flow shaft upstream. In case of

Fail-open valves, installation should be done with the shaft

down-stream.If the mounting of valve must be with the shaft upstream

in liquid service,

please consult our representative or contact our factory.

WARNING :

It has to be made sure that the flange face gasket

covers the seat retainer and body and surface when installing the

valve in line between flanges. There is a possibility of excessive

leakage downstream in case this is not done. Figure 1 can be

referred to for "Seat Insert/Snap-ring Configuration"

Before and during the installation process, the valve needs to

be fully closed.

WARNING :

Keeping clothing and body parts away from the

rotating disc and the seat when operating the valve can avoid any

possible serious injuries.

CAUTION :

DiskFlo has a self-centering seat and therefore the

valve should not be opened at any time during installation

process, keeping it closed until the complete installation of the

valve.

Air supply and instrument signal needs to be connected. Valve

positioners are usually present in Throttling valves. Separate two

connections are given for instrument signal and air supply. 150

psi air supply is suited for both cylinder and positioner. No need

for an air regulator is there till the supply pressure is 150 psi.

Unless the supply air is unusually clean and dry, an air filter is

recommended. There should be no leaks in connections.

CAUTION :

For valves with air filters, the air filter will not

perform properly if the air filter bowl is not pointing down.

NOTE :

There are certain cases wherein the air supply needs to

limited to 100 psi rather than 150 psi. The sticker pasted near the

upper air port on the cylinder indicates the same. An air regulator

must be installed to Ensure that the supply pressure is not exceeding

the desired 100 psi.

For proper disc rotation, it is necessary to have proper clearance

internally in the mating piping.

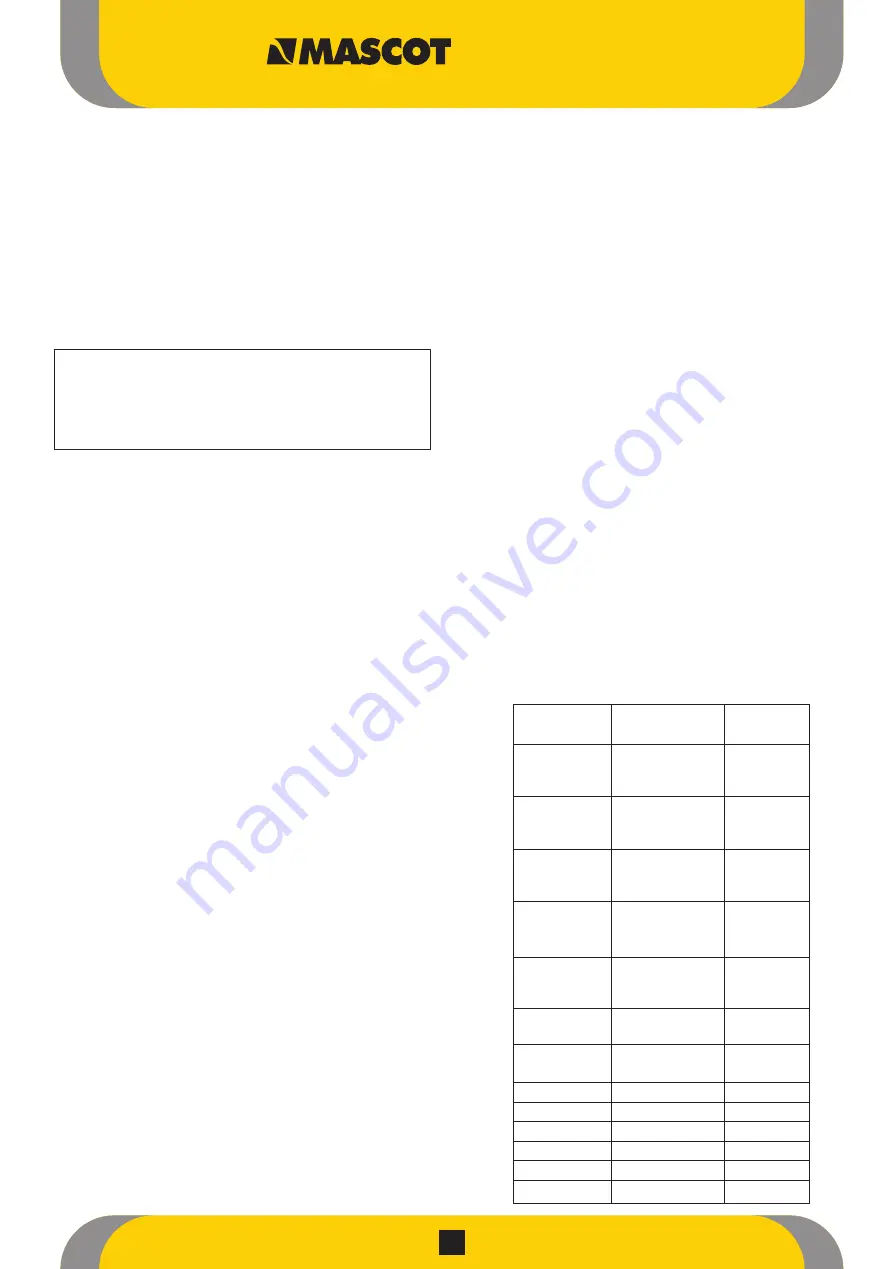

For proper sealing, the torque values as recommended should be

applied to line flange bolting for proper sealing - Refer Table 1

1.

2.

3.

4.

1.

2.

3.

4.

5.

6.

Table 1 : Flange Bolting Torques

Valve

Rating

Torques

Size (In.)

(ft.Lbs.)

150

118

2

300

118

600

118

150

118

3

300

209

600

209

150

118

4

300

209

600

505

150

209

6

300

209

600

505

150

209

8

300

337

600

728

10

150

337

300

728

12

150

337

300

728

14

150

505

16

150

505

18

150

728

20

150

728

24

150

1009

30

150

1009

DiskFlo Control Valves