Service manual

5 of 20

Atomic 3000 LED - Revision A, 11-30-2017

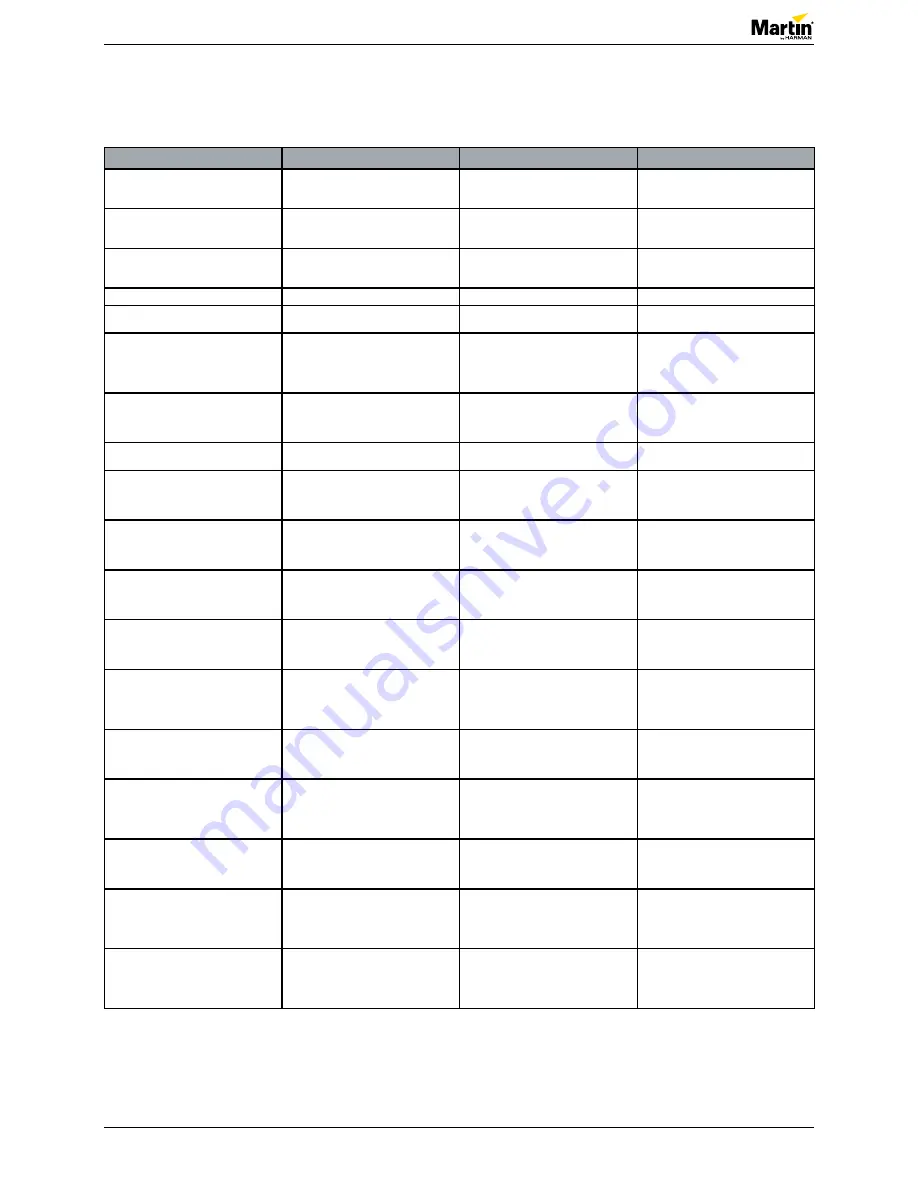

Troubleshooting

Overview of error codes

Error message

Symptom

Cause

Remedy

BANK (BANK NO ACCESS)

• Error during or after software upload

• Upload the software again.

•

Power off and then power on the fixture.

UITW (UI TEMP HIGH)

• The PCB sensor for the user interface

(LCD display and control panel) detects

abnormally high operating temperature.

•

Let the fixture cool down and restart it.

• Replace main PCB if the issue continues.

PUTW (PSU TEMP HIGH)

• The temperature sensor for the power

supply detects abonormally high operating

temperature.

• Check ambient temperature.

• Replace PSU if the issue continues.

SERV (SERVICE MODE)

• A safety loop error occured.

•

Power off and then power on the fixture.

SL W (SAFETY LOOP)

• The safety loop circuit is activated.

• Check the main LED thermal switch.

Replace it, if necessary.

BETW (BEAM TMP HIGH)

• The temperature sensor for the beam

pixel PCB detects abnormally high operating

temperature.

• Make sure the area around the main LED

engine is clean.

• Replace the main LED assembly if the

issue continues.

SLER (SAFETY LOOP)

• The safety loop circuit is activated.

• Check safety loop circuit.

• Replace the main LED thernal switch, if

necessary

COLD (FIXTURE COLD)

•

The fixture is too cold.

•

The fixture will run normally at normal

ambient temperature.

FAN (BASE 1 FAN ERR)

• Fan is not rotating.

• Feedback from the sensor indicates that

the fan is not rotating.

• Make sure the fan is not blocked or

damaged.

• Replace the fan, if necessary

FAN (BASE 2 FAN ERR)

• Fan is not rotating.

• Feedback from the sensor indicates that

the fan is not moving.

• Make sure the fan is not blocked or

damaged.

• Replace the fan, if necessary

FAN (BASE 3 FAN ERR)

• Fan is not rotating.

• Feedback from the sensor indicates that

the fan is not moving.

• Make sure the fan is not blocked or

damaged.

• Replace the fan, if necessary

FAN (BASE 4 FAN ERR)

• Fan is not rotating.

• Feedback from the sensor indicates that

the fan is not rotating.

• Make sure the fan is not blocked or

damaged.

• Replace the fan, if necessary

UITE (UI TEMP SEN ERR)

• Temperature sensor for the user interface

fails.

• The main PCB cannot register the

temperature sensor.

• Check all connections.

UITC (UI TEMP CUT OFF)

• Temperature sensor for the user interface

is at cut-off level.

•

Let the fixture cool down and restart it.

• If the ambient temperature is OK but the

issue persists, replace the main PCB.

PUTE (PSU TEMP SEN ERR)

• Temperature sensor for the power supply

fails.

• The main PCB cannot register the

temperature sensor.

• Check all connections.

PUTC (PSU TEMP CUT OFF)

• Temperature sensor for the power supply

is at cut-off level.

•

Let the fixture cool down and restart it.

• If the ambient temperature is OK but the

issue persists, replace the PSU.

BETE (BEAM TMP SEN ERR)

• Temperature sensor for the beam pixel

PCB fails.

• The main PCB cannot register the

temperature sensor.

• Check all connections.

BETC (BEAM TMP CUT OFF)

• Temperature sensor for the beam pixel

PCB is at cut-off level.

•

Let the fixture cool down and restart it.

• If the ambient temperature is OK but

the issue persists, replace the main LED

assembly.