9 of 12

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.MARSHALLTOWN.com

WS2643

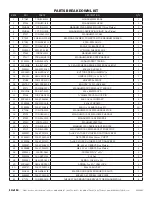

PROBLEM

CHECK FIRST

CHECK SECOND

CHECK THIRD

CHECK FOURTH

Difficulty cutting

Ensure cam lock is OFF.

If equipped, engage

power lobes (Model

226)

Make sure handle is

FULLY extended

Check blade

sharpness/condition

Inspect and lubricate bearings/

pins

Not cutting

completely through

material

Inspect pins for oblong/

wallowed orifice

Adjust front stroke stop

(MAGNUM shears)

Check bearings for

wear/play

Ensure blade is proper nominal

height

Blade sticking after

completing cuts

Check/remove &

replace blade stops if

damaged

Ensure blade screws are

tight

Remove anvil, turn it

over, reinstall

Check for marks on anvil

(overbite)

Rough or crushed

cuts

Check veneer thickness

(max= 1/16")

Check blade condition

(chips, burrs, breaks)

Ensure blade is honed

and sharp

Review approved materials list

Cuts aren't square

Loosen fence screws,

align fence, tighten

Check pins for uneven

wear

Inspect blade and anvil/

blade-stop for contact

Handle not returning

to open position

Ensure pins are

lubricated

Apply grease to contact

area of bearing

Lubricate axle bolts

Check springs for breakage

Material won't fit into

cut area

Check max thickness of

material for your shear

Reverse back stroke stop

Ensure blade is proper

nominal height

If you have two bearings, switch

which bearing is engaged

Cam lock pin bent/

stuck

Do not lift or carry

shear by the handle

Return handle slowly to

open position -

do not "let it fly"

Disengage cam lock pin

BEFORE cutting

Blade chipping

Hone as directed in

manual (~25 cuts, then

daily)

Do not cut stranded

bamboo

Do not cut high

pressure laminate

Check veneer thickness

(max=1/16")

Pin openings

wallowed out /

oblong where cam

axle passes through

Do not lift or carry

shear by the handle

Return handle slowly to

open position - do not "let

it fly"

Check veneer thickness

(max= 1/16")

Review approved materials list

Not cutting to edge

of material

Check fence alignment

- adjust if needed

Do not "angle" material

beyond the blade edge

Ensure angle fence(s)

are installed with WIDE

edge inward (620

model)

Before troubleshooting double-check the manual:

• Is your shear properly assembled?

• Is it being operated correctly?

• Is it properly lubricated?

• Has the blade been honed as recommended?

Visually inspect shear, watching for objects that might obstruct the blade or powerhead travel:

• Foreign material presence between the blade and anvil, in the pin springs or under the cam.

• Check your blade for chips, cracks or burrs.

• Make sure bearings are intact and lubricated. They should not be spinning/moving on the cam during use.

NOTE

: This troubleshooting is for all Bullet shears. If you are uncertain if it pertains to your shear, please contact

Marshalltown customer service.

TROUBLESHOOTING