8 of 12

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.MARSHALLTOWN.com

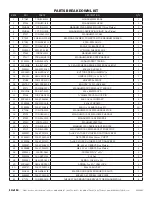

WS2643

MAINTENANCE

BEVELED SIDE

FLAT SIDE

(TABLE SIDE)

FLAT SIDE OF BLADE

HONING

STONE

HONING THE BLADE

Push the handle down until the blade is 1/8" (3mm) above

the tabletop. Place the provided Hone Stone against the

flat side of the blade. Slide the honing stone from one end

of the blade to the other 3-4 times. This will remove any

burrs from your blade.

When you first get your shear, you should hone after your

5th cut, then hone your blade every 10th cut for the first

100 cuts until your blade is broken in. From there, you only

need to hone once per job. Use caution when honing the

blade. The blade is sharp and can easily cause injury. Cut

resistant gloves are recommended when honing the blade.

For more information on honing your blade,

follow this QR Code link or URL below:

https://marshalltown.com/honing-your-blade

REPLACING THE BLADE

1. TURN SHEAR UPSIDE DOWN

Tip: put the shear on the edge of a sturdy table.

2. LOOSEN BLADE (I)

Using a 5/32" (4mm) hex key “Allen” wrench, remove the Button Head

Socket Cap Screws screws (J).

3. REMOVE BLADE

Hold blade by each end and carefully lift out of pocket

4. INSTALL BLADE

Hold blade by each end and carefully place into the blade pocket in the

head, with the flat side of the blade facing the table. Be sure that it is

firmly seated, and the pocket is clear of debris.

5. TIGHTEN THE BLADE

Using a 5/32" (4mm) hex key “Allen” wrench, replace & tighten the screws,

starting with the center screw.

J

I

SHARPENING THE BLADE

The blade can be sharpened to restore a one-sided, 21° – 22° knife edge. It is important to note that the blade must be

sharpened only on the beveled side, leaving the flat side flat.

We recommend that power grinding only be done professionally, as the blade must be fluid cooled during this process.

WARNING

USE EXTREME CAUTION! Blade is very sharp.

!

!