Rutland Furlmatic 910-4 Windcharger Installation & Operation

Doc No: SM-138 Iss. A 29.01.13

8

Marlec Eng Co Ltd

Tower Construction

The Furlmatic 910-4 is designed to fit inside an aluminium, stainless or steel

tube with an internal diameter of 41mm with a minimum wall thickness of 5mm.

A suitable mounting pole can be erected using a 6.5 metre (21 feet) galvanised

(medium) tube. The tube must be supported by a minimum of four guy lines.

The attachment points for the guy lines to the tower should be securely fixed to

the tower.

The guy wires should be a minimum of 4mm in diameter.

The shackles should be a minimum of 5mm in diameter.

Rigging screws should be a minimum of 5mm in diameter.

All items should be galvanised or stainless steel for protection against

corrosion.

Where guy lines are looped, the loop must incorporate a thimble and be fitted

with a minimum of three rope grips.

All ground fixings must be made suitable according to the terrain.

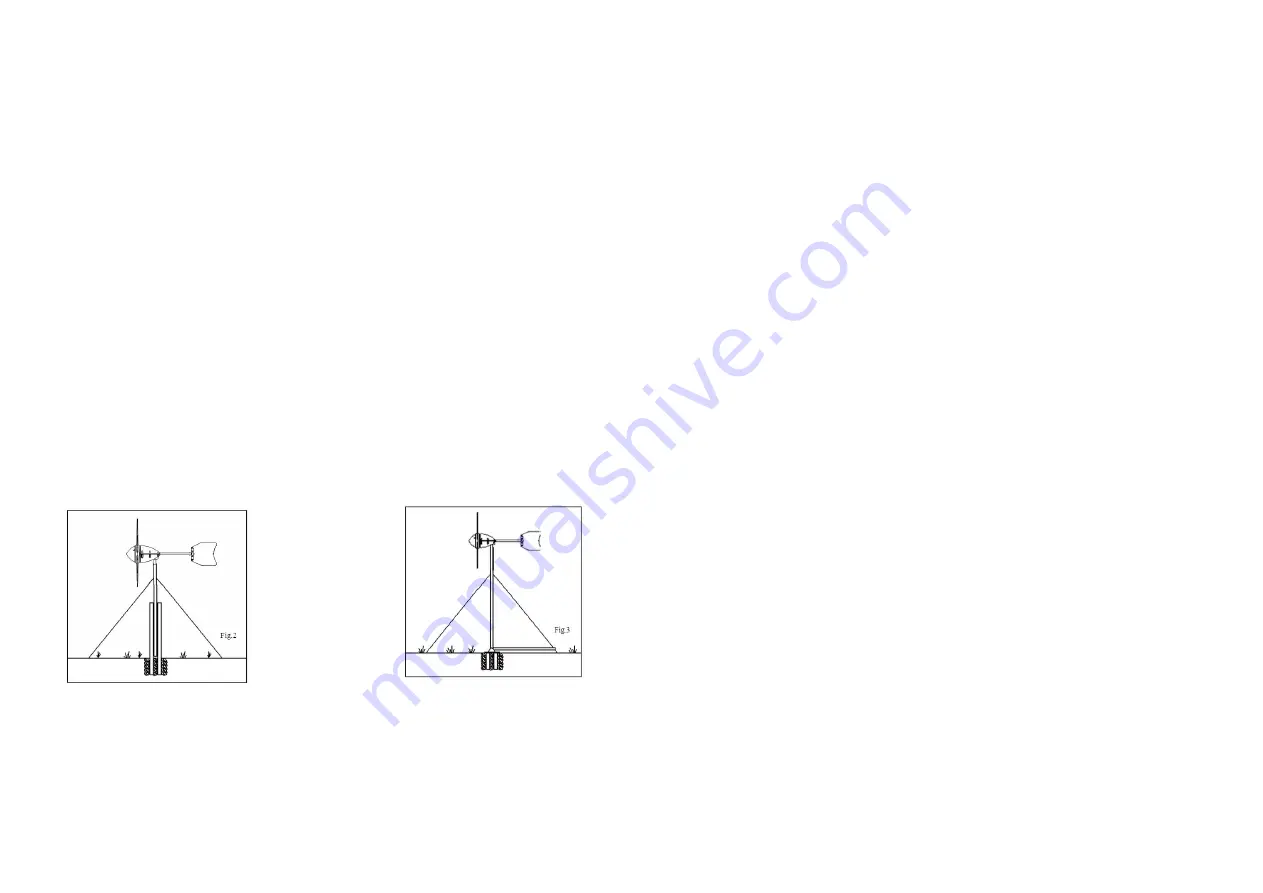

Pivot type towers are recommended as these allow for easier installation and

lowering for access to the wind generator. Two forms of pivot tower are

suggested in Figs 2 & 3. Non-guyed pivoting towers are available, for further

details contact the dealer or manufacturer.

NB: See the warnings section regarding the tower. It is essential that the tower

is maintained vertically to minimise lateral movement which interferes with the

effective operation of the furling tail.

Centre pivoted pole

Base pivoted with

Rutland Furlmatic 910-4 Windcharger Installation & Operation

Doc No: SM-138 Iss. A 29.01.13

13

Marlec Eng Co Ltd

Electrical Connection and Fitting To The Tower

Run the cable selected (see Table 1) down the inside of the pole.

Select one of the 2 basic systems on page 14 and follow the manual provided

with the charge regulator selected.

Connect the Windcharger flying lead to the cable protruding from the top of the

tower using the connector block supplied, taking care to observe polarity.

Connect the Windc to cable + and Windcharger – to cable –

Red is positive (+)

Black is negative (-)

Wrap the connection with insulation tape to secure/protect from the

environment. Alternatively join the cables using a latching type plug and

socket.

Locate the Windcharger into the tower whilst gently easing the cable from the

tower base to ensure the cable is not trapped. Secure the Windcharger to the

tower using the button cap screws and shake-proof washers provided. Tighten

using the 6mm Allen key supplied.

Up and Running

Four Point Final Checklist

Before raising and securing the wind generator:

1. Check the tightness of the blade & tail fixing screws and generator

mounting screws.

2. Check free rotation of the hub and yaw axis.

3. Check that the cable is not trapped.

4. Check that all electrical connections are secure and safe.

The wind generator can now be raised into position.

Take care to avoid all moving parts when raising and lowering the wind

generator.

When raised, secure the structure firmly in an upright position.

Caution-The performance of your Windcharger will be impaired if the pole is

not vertical.