Rutland Furlmatic 910-4 Windcharger Installation & Operation

Doc No: SM-138 Iss. A 29.01.13

14

Marlec Eng Co Ltd

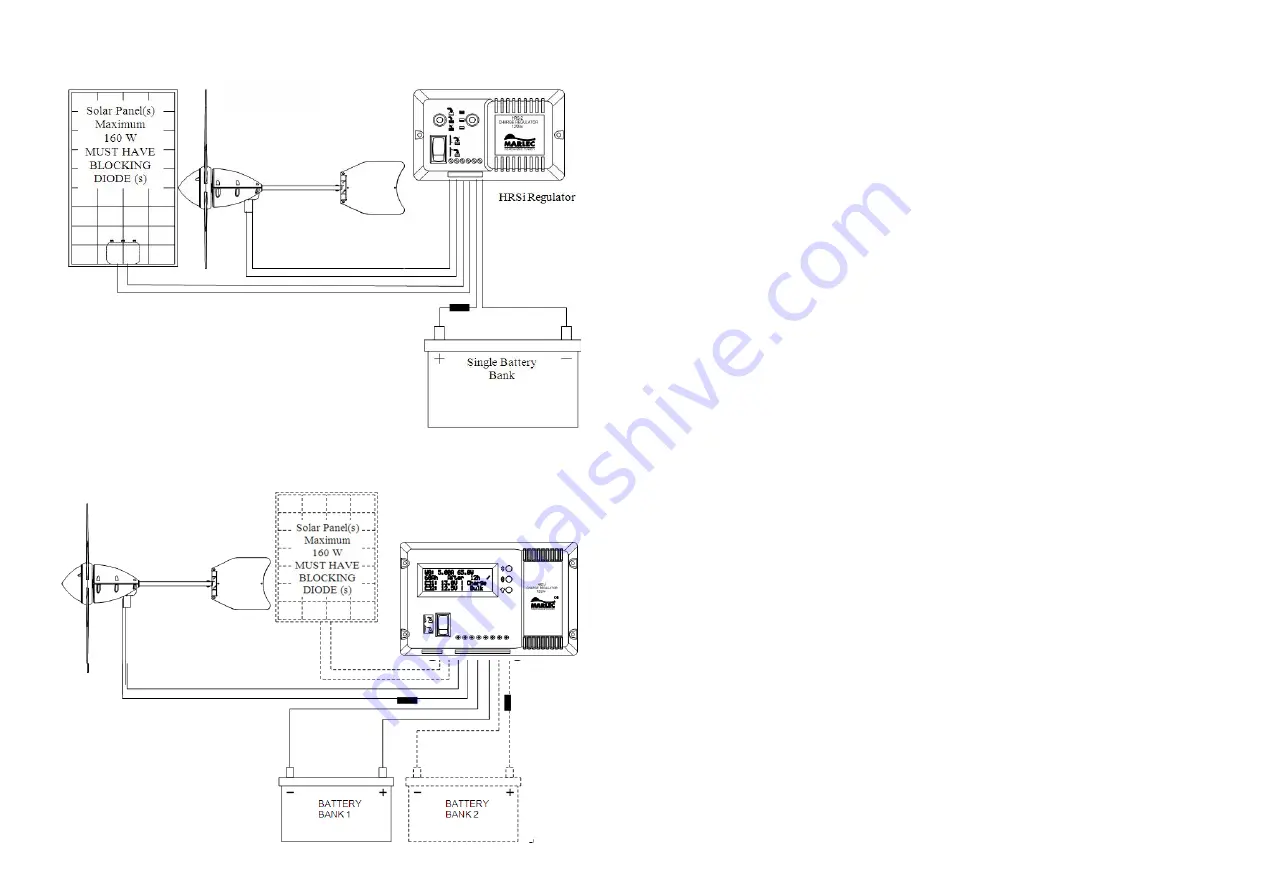

Typical Wiring Diagrams For The Rutland FM910-4 Windcharger

Rutland FM 910-3 with HRSi Charge Regulator Wiring

Diagram

( OPTIONAL SOLAR PANEL FITTED )

Rutland FM 910-3 with HRDi Charge Regulator Wiring

Diagram

Rutland Furlmatic 910-4 Windcharger Installation & Operation

Doc No: SM-138 Iss. A 29.01.13

7

Marlec Eng Co Ltd

Principle Of Operation

Generator

The 3 phase ac generator is driven directly by the aerofoil blades, rotating

permanent magnets around the fixed stator winding. The variable frequency

alternating current is rectified within the generator housing, and the resulting

rectified current is transmitted via the sliprings and brushes at the yaw axis to

the output cable.

Winding Over-Temperature Protection

The generator stator winding incorporates embedded thermal protection to

protect the winding from damage due to over temperature during extreme winds.

On reaching the thermal protection limit, the device will reduce generator output

current to allow the winding to cool, whereupon normal performance will be

resumed. If the thermal protection is active, the turbine may reduce to a slow

rotational speed with a corresponding reduction in charge current, this is normal.

Furling Tail System

The tail assembly is designed to direct the turbine into the main direction of the

wind at windspeeds up to approx 15m/s. Above this the automatic “furling”

mechanism is activated to turn the generator at an angle to the wind to protect

the turbine, generator and supporting structure from severe electrical and

mechanical loads due to high winds. When the wind speed subsides, the tail

assembly will automatically return the turbine to normal operation. In prolonged

gusty & turbulent conditions, the system may be seen to repeat this cycle many

times. Power will be reduced during furling. For effective operation of the furling

system the wind turbine must be sited to ensure it is as free as possible from

turbulence and in a stable upright position.