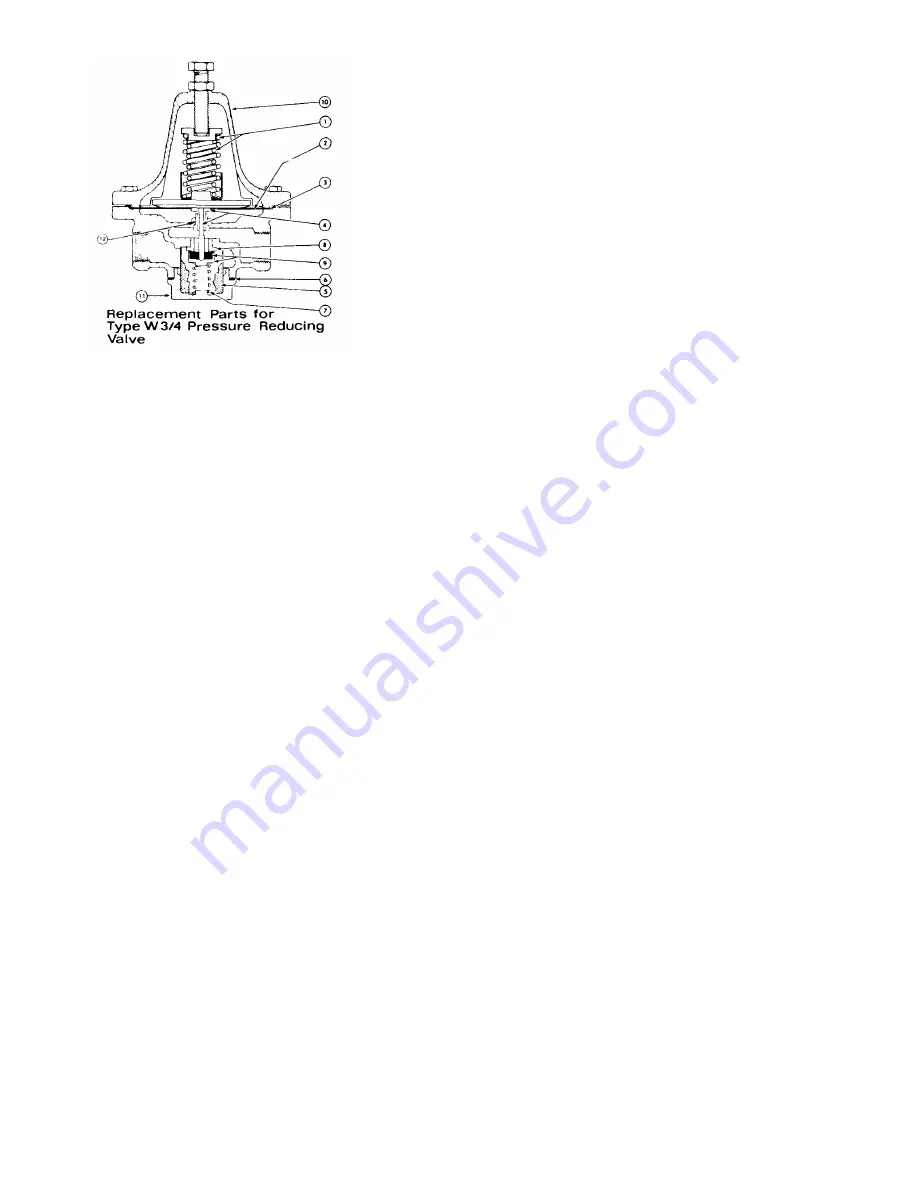

ITEM NO. PART NO.

DESCRIPTION

1

10-1083

Adjusting Spring

2

10-1082

Diaphragm

3

10-1075

Diaphragm Gasket

4

10-1076

Diaphragm Button & Stem

Assembly

5

10-1077

Strainer

6

10-1078

Bottom Plug Gasket

7

10-1079

Bottom Spring

8

10-1080

Seat

9

10-1081

Disc Assembly

10

10-1033

3/4" Complete Valve-Painted

11

10-1034

3/4" Complete Valve-Chrome

Bottom Plug

12

10-0893

Valve Stem Guide

WATTS PRESSURE REDUCING VALVES - 3/4"

To provide adequate steam pressure regulation, your

unit may be equipped with a Watts steam pressure re-

ducing valve. The 3/4" Watts pressure reducing valve is

designed to operate from a 7 to 50 P.S.I, source of

steam pressure and reduce this to 5 P.S.I, for delivery to

your cooker. Installation must be made from your source

of steam supply, through the pressure reducing valve,

and into the manifold input part of the steam cooker.

WARNING: Before final connection is made, blow

down your steam line to remove all dirt, scale,

packing and compound which may have

accumulated during the installation of piping to the

cooker.

OPERATION OF WATTS 3/4" REDUCING VALVE

Steam enters the valve at the inlet port and passes up-

ward through the seat (8) into the discharge side of the

valve. As pressure in the discharge side increases, it

forces the diaphragm (2) upward, overcoming the tension

of the adjusting spring (1) and closing valve. As the

pressure drops, the adjusting spring forces the

diaphragm down, reopening the valve. Where demand

and initial pressures are fairly constant, the valve opens

to the proper position and maintains the desired reduced

pressure.

ADJUSTING WATTS 3/4" REDUCING VALVE

1. Release the adjusting screw lock nut and loosen the

adjusting screw enough to release all tension on ad-

justing spring (1).

2. Turn steam on slowly. Then turn adjusting screw

clockwise just enough to allow the valve to open

slightly. Allow cooker to operate in this manor

several minutes.

3. Turn adjusting screw down slowly, at intervals,

until reduced pressure reaches the desired Point.

(5 P.S.I.)

4. Tighten adjusting screw lock nut.

5. If chattering noise should occur turn adjusting screw

located in bottom half of valve body, clockwise or

counter-clockwise, until chattering stops.

INSPECTION - MAINTENANCE

Reports of unsatisfactory regulation of the pressure

reducing valve is usually due to dirt, pipe compound,

etc., blocking the internal strainer, or gumming up the

seat and disc assembly. To clean the strainer, seat,

and disc assembly remove the bottom plug (6) and

remove strainer screen (5), bottom spring (7) and disc

assy. (9) Clean the lower part of the valve. This can be

accom plished without removing the valve from the line

or unbolting the cover. If cleaning the strainer and disc

assy. does not correct fault, the disc assy. and seat

should be replaced. Also the top cover should be re-

moved and the diaphragm button stem assembly

should be removed and cleaned.

REPAIRS

The following item should be cleaned or replaced

should the value fail to operate properly.

1. Both the disc assembly (9) and strainer (5) are re-

moved by removing the bottom plug (11) and bottom

spring (7). Upon cleaning or replacing these items,

be sure that the disc assembly (9) is seated properly

on the stem assembly (4) otherwise the stem

assembly will be bent restricting its movement and

the regulation of steam through the valve.

2. Should there be a restriction in the diaphragm button

and stem assembly (4) it will cause a drop in steam

flow or large fluctuations in steam pressure. It is

then necessary to replace diaphragm button and

stem assembly (4), valve stem guide (12) and

diaphragm gasket (3) as well as those items in step

1.

Upon completion of the above and removal of any

loose scale, which may be found in the valve, the valve

should be reassembled; and upon installation, function

properly.

5010