Page 8

000662MAN-03

01 MAR 2012

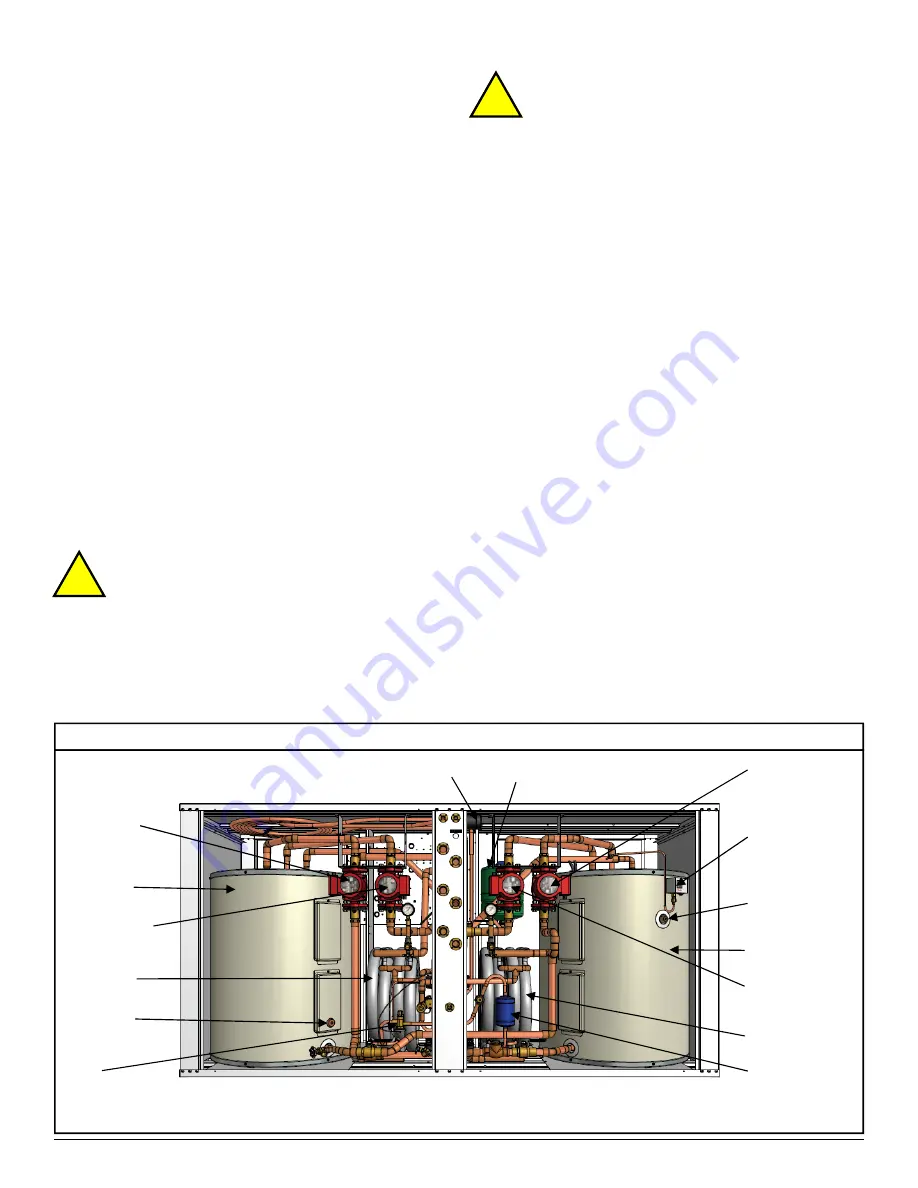

DIAGRAM B - Circulator and Major Component Locations

25. Open the fill hose valve.

26. Purge until no air can be heard leaving the system.

27. Close the Cold Zone Ball Valve

28. Open the top isolation valve of the Cold Zone Circulator.

29. Purge until no air can be heard leaving the system.

30. Close the Cold Indoor Boiler Drain.

31. Move the drain hose to the Hot Indoor Boiler Drain.

32. Open the top isolation valve of the Cold Indoor Circulator.

33. Open the Hot Indoor Boiler Drain.

34. Purge until no air can be heard leaving the system.

35. Close the Hot Indoor Boiler Drain.

36. Close the Cold Zone Boiler Drain when the system reaches

the desired pressure level.

37. Close the fill hose valve and disconnect the hoses.

38. Open the Cold Zone and Cold Indoor Ball Valves.

39. Open the Hot Zone and Hot Indoor Ball Valves.

40. Do a final check of all ball valves and isolation valves to

ensure they are all open.

Repeat the above procedure as necessary to ensure that

all of the air has been removed, then remove the purging equip-

ment.

DOMESTIC HOT WATER

CONNECTIONS

A typical piping diagram for a two tank (pre-heat tank) con-

figurations can be found in

drawing 000970PDG at the end of

this section

. Be sure to note the position of the check valve and

the direction of water flow. Other configurations are possible,

and there may be multiple units tied together in larger buildings.

CAUTION: Use only copper pipe to connect the

desuperheater. Should the DHW thermostat fail,

the water temperature could rise to as high as

200°F (93°C).

Ensure the tank is filled with water and under pressure

before activating the heat pump. Slightly loosen the boiler drain

on the DHW Out pipe to allow air to escape from the system

before the unit is started. This step will make certain that the

domestic hot water circulator in the unit is flooded with water

when it is started.

CAUTION: the domestic hot water pump is water

lubricated; damage will occur to the pump if it is

run dry for even a short period of time.

The DHW loop may have to be purged of air several times

before good circulation is obtained. A temperature difference

between the DHW In and DHW Out can be felt by hand when

the circulator pump is operating properly.

The final tank should be set to

140°F(60°C).

The pre-heat

tank does not require electric elements. This setup takes full

advantage of the desuperheater as it is the sole heat provider to

the pre-heat tank. The desuperheater remains active during the

compressor runtime until the pre-heat tank has been completely

heated by the desuperheater alone. This setup is more energy

efficient than a single tank setup.

CAUTION: If two (2) shut-off valves are located on the

domestic hot water ines as shown in the diagram, a pres-

sure relief valve must be installed to prevent possible dam-

age to the domestic hot water circulator pump should both

valves be closed.

!

Evaporator

Cold Indoor

Circulator

(Evaporator)

Hot Zone

Circulator

Cold Zone

Circulator

DHW Circulator

Condenser

Hot Tank

Cold Tank

Expansion Tank

Cold Tank

Probe

Hot Tank

Probe

Safety Pressure

Switch for Electric

Backup

Hot Indoor

Circulator

(Condenser)

TXV

Filter-drier

!

Summary of Contents for EMWT-65-HACW-P-1T

Page 9: ...01 MAR 2012 Page 9 000662MAN 03...

Page 10: ...Page 10 000662MAN 03 01 MAR 2012...

Page 13: ...01 MAR 2012 Page 13 000662MAN 03...

Page 16: ...Page 16 000662MAN 03 01 MAR 2012...

Page 19: ...01 MAR 2012 Page 19 000662MAN 03...

Page 34: ...Page 34 000662MAN 03 01 MAR 2012 REFRIGERATION CIRCUIT DIAGRAM...

Page 35: ...01 MAR 2012 Page 35 000662MAN 03 REFRIGERATION CIRCUIT DIAGRAM continued...

Page 41: ...01 MAR 2012 Page 41 000662MAN 03 ELECTRICAL DIAGRAMS 230 1 60...

Page 42: ...Page 42 000662MAN 03 01 MAR 2012 ELECTRICAL DIAGRAMS 230 1 60 continued...

Page 43: ...01 MAR 2012 Page 43 000662MAN 03 Back View Front View CASE DETAILS Right Side View...