2.2. Power Supply Selection

• The power supply used to power the OIT should have an output b12

and +30 VDC, meeting Class 2 power requirements. The voltage should

measure b12 and +30V at the OIT between Pins 1 and 2 of the power

connector. A 24 VDC, 1.2 amp linear power supply dedicated to the OIT is

recommended.

• The power cable for the OIT should be 18AWG 2-conductor stranded wire with

a shield wire and protective shield (foil or braid). The shield of the OIT power

cable must be connected to earth ground at both ends of the cable. Please refer to

the “Connect OIT to Power” section for more information.

• A power line filter installed at the AC input to the OIT power supply is highly

recommended as a safeguard against conducted RF noise, which is often present

on factory power lines. The wires connecting the output of the power line filter

to the power supply should be kept as short as possible to minimize any

additional noise pickup. The case of the power line filter should be connected to

a quiet earth ground. The power line filter should have a current rating of at least

three amps with common mode and differential mode attenuation.

• The power supply that provides power to the OIT should not be used to power

switching relays or solenoids unless noise filter caps are connected to each relay.

2.3. OIT Cable Routing

• Input and output (I/O) wiring must be in accordance with Class I, Division 2

wiring methods and in accordance with the authority having jurisdiction.

• Always route the OIT communication cable and power cable away from any AC

voltage or PLC/host control wires.

• Never bundle the OIT cables together with 120 VAC power wires or with relay

wiring.

• Try to keep at least 8 inches (20 cm) of separation between the OIT cables and

other power wiring. If voltages greater than 120 VAC are used in the system,

greater separation is required.

• If the OIT cables must come near AC wiring, make sure they cross at 90 degrees.

• Running AC power wires in a separate grounded conduit is the preferred method

for electrical noise reduction.

1010-0104, REV 03

8

OIT3185A/4185A

Figure 2 Power Line Filter Connection

INSTALLATION MANUAL

17

1010-0104, REV 03

SDF1

SDF2

SDF3

SDF4

SDF5

SDF6

SDF7

SDF8

F1

F2

F3

F4

F5

F6

F7

F8

F9

F10

F11

F12

F13

F14

F15

F16

3160

Emulation

ENTER

CLEAR

Alarm

Ack

Next

Msg

Help

Toggle

Last

Msg

Del

7

4

1

8

5

2

9

6

3

Page

Down

0

F1

F4

F2

F5

F3

F6

24

Function

Keys

Check

Dimension

4.00"

[101.6

mm]

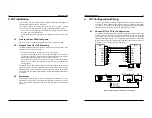

Figure 8 OIT3185/4185 Predefined Keypad Templates