Page 45

Version 2022-12-20

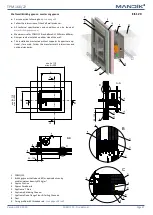

FDMQ 120 - Fire damper

TPM 166/22

■

Dampers are delivered on a pallets. As standard, the

dampers are wrapped in plastic foil for protection during

transport and must not be used for long-term storage of

the equipment . Changes in temperature during transport

may cause condensation of water vapour inside the

packaging and thereby condisitions may arise inside the

packaging that are suitable for corrosion of materials used

in the equipment (e.g. white corrosion on zinc-coated

items or mould on calcium silicate). Therefore, it is necess-

ary to remove the transport packaging immediately after

unloading to allow air to circulate around the product.

■

The equipment must be stored in clean, dry, well

ventilated and dust-free environment out of direct sun-

light. ensuring protection against moisture and extremes

of temperatures (minumum tempe5°C) the equip-

ment must be protected against mechanical and accid-

ental damage prior to installation.

■

Another required packaging system should be approved

and agreed by manufacturer. Packaging material is not

returnable in case that another packaging system

(material) is required and used and it is not included into

final price of damper.

■

For unloading and further manipulation with the damper

is necessary to use appropriate tooling (forklifts) due to

damper weight. Dampers are fragile.

■

Dampers are transported by box freight vehicles without

direct weather impact, there must not occur any shocks

and ambient temperature must not exceed +50°C.

Dampers must be protected against impact when

transported and manipulated. During transportation, the

damper blade must be in the "CLOSED" position.

■

Dampers are stored indoor in environment without any

aggressive vapours, gases or dust. Indoor temperature

must be in the range from -30°C to +50°C and maximum

relative humidity 95% (avoid condensation on the damper

body). Dampers must be protected against impact when

transported and manipulated.

■

Assembly, maintenance and damper function check can

be done only by qualified and trained person, i.e.

“AUTHORIZED PERSON” according to the manufacturer

documentation. All works done on the fire dampers must

be done according international and local norms and laws.

■

All effective safety standards and directives must be obse-

rved during damper assembly.

■

To ensure reliable damper function it is necessary to avoid

blocking the closing mechanism and contact surfaces with

collected dust, fibre and sticky materials and solvents.

■

Flange and screw joints must be conductively connected

to protect against dangerous contact. 2 galvanized fan

shape pads that are placed under the head of one screw

and a fastened nut are used for conductive connection.

V. TRANSPORTATION AND STORAGE

Logistic terms

VI. ASSEMBLY, ATTENDANCE AND MAINTENANCE

Assembly

■

A special lever (part of the actuator) may be used to

manually set the dampers to any position. When the lever

is turned in the direction of the arrow, the damper blade

turns to its open position. As the blade movement is

stopped, in every position, the actuator will be locked.

Unlocking is possible even manually as per instructions on

the actuator, or by the activation of the supply voltage.

■

If the actuator is manually locked, the damper blade will

not close in the event of a fire after the activation of the

BAT thermoelectric trigger. To restore correct damper

operation, the actuator must be unlocked (manually or by

applying power supply).

Manual operation - actuator control without electric voltage