3

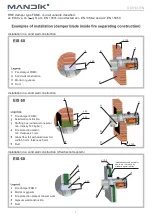

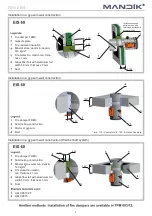

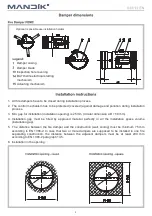

6. Installation in the opening.

1. All fire dampers have to be closed during installation process.

2. The control mechanism has to be protected (covered) against damage and pollution during installation

process.

3. Min. gap for installation (installation opening) is 25 mm (circular dimension

Ø

D + 50 mm).

4. Installation gap must be filled by approved material perfectly in all the installation space volume

(installation gap).

5. The distance between the fire damper and the construction (wall, ceiling) must be minimum 75 mm

according to EN 1366-2. In case that two or more dampers are supposed to be installed in one fire

separating construction, the distance between the adjacent dampers must be at least 200 mm

according to EN 1366-2 paragraph 13.5.

Damper casing

Damper blade

Inspection hole covering

BAT thermoelectrical starting

mechanism

Actuating mechanism

Optional is possible use installation holders

Summary of Contents for FDMC

Page 1: ......