○

R

○

Y

○

G

○

O

○

B

TERMINAL

STRIP

○

C

○

R

○

G

○

O

○

Sy

○

1

○

Y

○

L

○

Sc

○

2

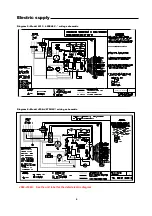

Electric

supply

5

Diagram

1:

Manual

changeover

thermostat

Diagram

2: Automatic

changeover

with

night

setback

Diagram

3:

Automatic

changeover

thermostat with

night

setback/setup

and

override

Electrical

Electrical

Electrical

Electrical

Service

Service

Service

Service

and

and

and

and

Fusing

Fusing

Fusing

Fusing

Warning:

To

avoid

severe

electrical

shock,

turn

off

power

before

servicing

controls

.

Unit

must

be

installed

in

compliance

with

NEC

and

local

codes.

Route

power

wires

through

a

properly sized disconnect switch.

Consult

the

wiring

diagrams

in

this

manual

and

inside

the

cover

of

the

electrical

box

to

complete

the

connection.

See

nameplate

for

proper

fuse

sizing,

minimum

circuit

ampacity

and

voltage

requirements.

If

an

auxiliary

electrical

heater

is

used,

it

must

be

installed

with

a

power

supply

separate

from

the

heat

pump.

Control

Control

Control

Control

W

W

W

Wiring

iring

iring

iring

See

Diagrams

1

through

4

All

heat

pump

functions

are

controlled

by

remote

thermostat

and

must

be

wired

as

shown,

using

approved

copper

wire.

Auxiliary Dry Contact (N.C.)

Common for Night Setback/Setup and Emergency Shutdown Input Signals (—)