Model TE-703/704

Technical Information

TI.703/704-03

PIPE TEMPERATURE SENSORS

Page 2 of 4

RoHS

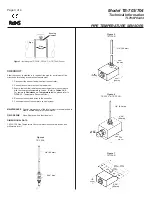

Mount the Immersion Sensor:

Refer to

Figures 4, 5 & 6

for mounting

dimensions.

1.

TE-703-A:

a. Loosen the compression fitting and remove the probe. Refer to

Figure 1

.

b. Screw the adapter into the thermowell.

c. Apply A-505 thermal compound to the probe tip and insert the probe until it

is seated against the thermowell.

d. Tighten the nut.

TE-703-B, C, or D:

a. Loosen the set screw. Refer to

Figure 1

.

b. Remove the adapter and thread it into the thermowell. Tighten.

c. Apply A-505 thermal compound to the probe tip and insert the probe until it

is seated against the thermowell. Ensure that the set screw is accessible.

d. Lock the adapter into place and tighten the set screw.

e. Loosen the cover screws and rotate the cover out of the way.

2. Make the wiring connections.

3. Rotate and screw the cover back into place.

Mounting

TE-704-A:

1. Scrape any rust or scale off the pipe surface.

2. Apply a thin layer of A-505 thermal compound to the sensor.

3. Position the sensor flat against the pipe and fasten with a hose

clamp or

nylon ties (not provided).

Refer to

Figure 2

.

4. Make the wiring connections. Insulate around the sensor if

necessary.

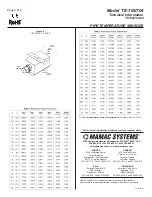

TE-704-B, C, or D:

Refer to

Figures 7 & 8

for mounting dimensions.

1. Scrape any rust or scale off the pipe surface.

2. Apply a thin layer of A-505 thermal compound to the sensing

element. Refer to

Figure 3

.

3. Position the sensor’s sensing element so that it makes contact

with the pipe and fasten with two pipe clamps (

not provided

).

4. Loosen the cover screws and rotate the cover out of the way.

5. Make the wiring connections. Rotate and screw the cover back

into place.

Figure 1

- Installing the Immersion Sensor

Figure 2

- Installing the TE-704-A Sensor

Inspection

Requirements

INSTALLATION

Inspect the package for damage. If damaged, notify the

appropriate carrier immediately. If undamaged, open the

package and inspect the device for obvious damage.

Return damaged products.

•

Do not use on oxygen service, in an explosive/hazardous

environment, or with flammable/combustible media.

•

Disconnect power supply before installation to prevent electrical

shock and equipment damage.

•

Make all connections in accordance with the job wiring diagram

and in accordance with national and local electrical codes. Use

copper conductors only.

•

Use electrostatic discharge precautions (e.g., use of wrist

straps) during installation and wiring to prevent equipment

damage.

•

Avoid locations where severe shock or vibration, excessive

moisture or corrosive fumes are present. NEMA-4 housings are

intended for outdoor use primarily to provide a degree of

protection against wind-blown dust, rain, and hose-directed

water.

•

Do not exceed ratings of the device.

•

Tools (

not provided

)

- Digital Volt-ohm Meter (DVM)

- Appropriate screwdriver for mounting screws

- Appropriate drill and drill bit for mounting screws

•

Appropriate accessories

•

Two #8 self-tapping mounting screws (

not provided

)

•

Training:

Installer must be a qualified, experienced technician.

Warning:

Caution:

Set screw

Thermowell

Pipe

Compression

fitting

Thermowell

Thermowell

Pipe

Nylon

tie

Sensor