9 ENGLISH

NOTE:

During the operation of switch trigger, the impact force grade cannot be changed.

Changing the torque setting

(screwdriver mode)

The fastening torque can be adjusted by pressing the

button

in screwdriver mode.

The numbers on the LED display shows torque setting.

The fastening torque is minimum at the number 1 and

maximum at the number 9. The indication "P" is a spe-

cial mode for fastening self drilling screws.

Every time the button

is pressed, the torque setting

changes from 1 to 9 and P, and then returns to 1.

The torque setting changes fast by keeping pressing

the button.

P mode is suitable for fastening self drilling screws into

steel plates in the following conditions.

•

With speed change lever at "2" side, fastening

max. 4 mm screw into total max. 3.2 mm steel

plates.

•

With speed change lever at "1" side, fastening

max. 5 mm screw.

Before an actual operation, drive a trial screw into

your material or a piece of duplicate material to deter

-

mine which torque level is required for a particular

application.

First, try to fasten the screw at "1". Then increase the

number to continue fastening. Hold the tool firmly during

operation.

CAUTION:

Don't fasten the machine screw on P

mode. It may twist your wrist suddenly and result in

personal injury.

NOTE:

•

Make sure to check the number on LED display

before operation. If the number is not indicated,

contact your nearest Makita service center.

•

When the remaining battery capacity gets low

in the screwdriver mode, the light flashes a few

times when fastening the screw completely. In

this case, recharge the battery. If you keep oper

-

ating, you may not obtain the desired torque.

•

During pulling the switch trigger, the torque

setting cannot be changed.

•

For approximately one minute after releasing

the switch trigger, the torque setting can be

changed. if you want to change the torque set

-

ting after that, pull the switch trigger again.

•

The number of torque setting does not mean

specific torque rate.

Empty signal for remaining battery

capacity

(Country specific)

►

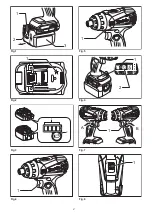

Fig.10:

1.

Battery capacity

The remaining battery capacity will be signaled on the

LED display when pulling the switch trigger.

The remaining battery capacity is shown as the follow

-

ing table.

LED indicator status

Remaining battery capacity

About 50% or more

About 20% - 50%

About less than 20%

NOTE:

•

When the LED display goes off, the tool is turned

off to save the battery power. To check the remain

-

ing battery capacity, slightly pull the switch trigger.

•

The LED display goes off approximately one

minute after releasing the switch trigger.

•

When the temperature of the tool gets high, the light flashes

once per second for one minute, and then the LED display

goes off. In this case, cool down the tool before operation.

ASSEMBLY

CAUTION:

•

Always be sure that the tool is switched off and

the battery cartridge is removed before carrying

out any work on the tool.

Installing or removing driver/drill/

socket bit

►

Fig.11

Use only the driver/drill/socket bit shown in the figure.

Do not use any other driver/drill/socket bit.

For tool with shallow bit hole

A=12 mm

B=9 mm

Use only these type of bit. Follow the

procedure (1).

(Note) Bit-piece is not necessary.

For tool with deep bit hole

To install these types of bits, follow

the procedure (1).

To install these types of bits, follow

the procedure (2).

(Note) Bit-piece is necessary for

installing the bit.

A=17 mm

B=14 mm

A=12 mm

B=9 mm