16 ENGLISH

Indicator lamps

Remaining

capacity

Lighted

Off

Blinking

Charge the

battery.

The battery

may have

malfunctioned.

NOTE:

Depending on the conditions of use and the

ambient temperature, the indication may differ slightly

from the actual capacity.

Switch action

WARNING:

Before installing the battery car

-

tridge into the tool, always check to see that the

switch trigger actuates properly and returns to

the "OFF" position when released.

WARNING:

NEVER defeat the lock-off button

by taping down or some other means.

A switch with

a negated lock-off button may result in unintentional

operation and serious personal injury.

WARNING:

NEVER use the tool if it runs when you

simply pull the switch trigger without pressing the lock-off

button.

A switch in need of repair may result in unintentional

operation and serious personal injury. Return tool to a Makita

service center for proper repairs BEFORE further usage.

To prevent the switch trigger from being accidentally

pulled, a lock-off button is provided. To start the tool,

depress the lock-off button and pull the switch trigger.

Release the switch trigger to stop.

►

Fig.10:

1.

Switch trigger

2.

Lock-off button

NOTICE:

Do not pull the switch trigger hard

without pressing in the lock-off button.

This can

cause switch breakage.

CAUTION:

The tool starts to brake the cir

-

cular saw blade rotation immediately after you

release the switch trigger. Hold the tool firmly to

respond the reaction of the brake when releasing

the switch trigger.

Sudden reaction can drop the tool

off your hand and can cause a personal injury.

Automatic speed change function

This tool has "high speed mode" and "high torque

mode".

The tool automatically changes the operation mode

depending on the work load. When the work load is low,

the tool will run in the "high speed mode" for quicker

cutting operation. When the work load is high, the tool

will run in the "high torque mode" for powerful cutting

operation.

►

Fig.11:

1.

Mode indicator

The mode indicator lights up in green when the tool is

running in "high torque mode".

If the tool is operated with excessive load, the mode indicator

will blink in green. The mode indicator stops blinking and then

lights up or turns off if you reduce the load on the tool.

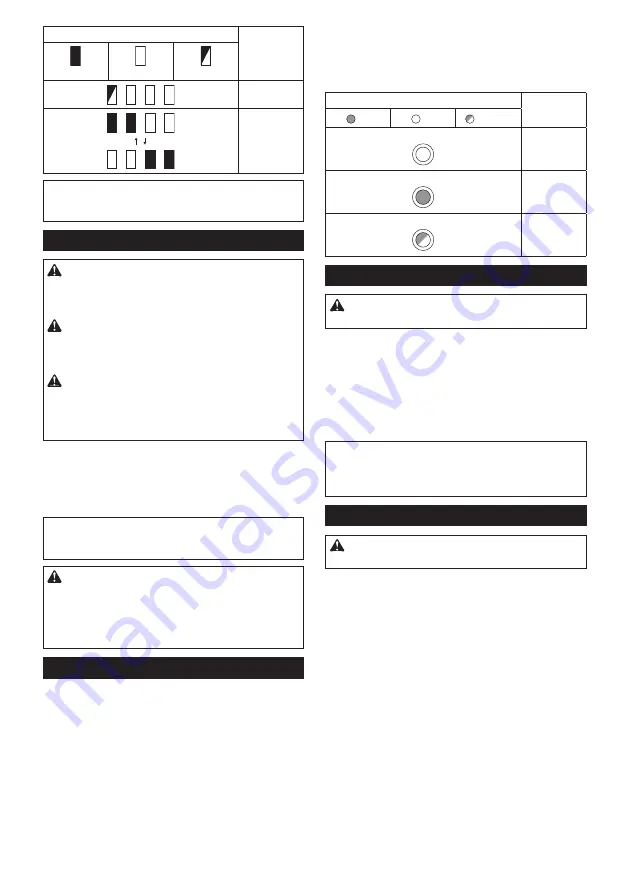

Mode indicator status

Operation

mode

On

Off

Blinking

High speed

mode

High torque

mode

Overload

alert

Adjusting depth of cut

CAUTION:

After adjusting the depth of cut,

always tighten the lever securely.

Loosen the lever on the depth guide and move the base

up or down. At the desired depth of cut, secure the base

by tightening the lever.

For cleaner, safer cuts, set cut depth so that no more

than one blade tooth projects below workpiece. Using

proper cut depth helps to reduce potential for danger-

ous KICKBACKS which can cause personal injury.

►

Fig.12:

1.

Lever

NOTICE:

If the base doesn't slide up or down

smoothly, the depth guide may have been tilted. In

this case, adjust the depth guide (refer the section

about adjusting the depth guide).

Bevel cutting

CAUTION:

After adjusting the bevel angle,

always tighten the clamping screws securely.

Loosen the clamping screws. Set for the desired angle by

tilting accordingly, then tighten the clamping screws securely.

►

Fig.13:

1.

Clamping screw

Positive stopper

The positive stopper is useful for setting the des-

ignated angle quickly. Turn the positive stopper so

that the arrow on it points your desired bevel angle

(22.5°/45°/60°). Loosen the lever and then tilt the tool

base until it stops. The position where the tool base

stops is the angle you set with the positive stopper.

Tighten the lever with the tool base at this position.

►

Fig.14:

1.

Positive stopper

-1°-bevel cutting

To perform -1°-bevel cutting, loosen the clamping

screws and press the levers toward the direction of the

arrow in the figure. Then set the bevel angle to -1° and

tighten the clamping screws.

►

Fig.15:

1.

Lever

Summary of Contents for DHS900ZU

Page 2: ...Fig 1 Fig 2 Fig 3 Fig 4 Fig 5 Fig 6 1 2 3 4 Fig 7 2 ...

Page 3: ...3 1 2 B A Fig 8 1 2 Fig 9 1 2 Fig 10 1 Fig 11 1 Fig 12 1 1 Fig 13 1 Fig 14 1 Fig 15 3 ...

Page 4: ...2 1 Fig 16 1 Fig 17 1 Fig 18 1 1 2 Fig 19 2 1 4 3 Fig 20 1 2 3 4 Fig 21 4 ...

Page 6: ...Fig 29 1 Fig 30 1 1 2 Fig 31 1 1 2 Fig 32 1 Fig 33 1 Fig 34 6 ...

Page 7: ...1 Fig 35 Fig 36 1 Fig 37 1 3 4 2 Fig 38 1 2 3 Fig 39 1 Fig 40 7 ...

Page 8: ...1 2 1 2 Fig 41 Fig 42 1 Fig 43 1 2 Fig 44 1 Fig 45 1 Fig 46 8 ...

Page 9: ...1 2 1 2 Fig 47 1 1 2 Fig 48 1 1 Fig 49 1 2 Fig 50 1 Fig 51 9 ...

Page 10: ...1 1 A B 2 Fig 52 10 ...

Page 131: ...131 ...