P 4 / 8

ASSEMBLING

Chain oil

Normal condition

(If Chain oil is not delivered from the exit

after completing repairing, there is the possibility

that Filter in chain oil exit is clogged. Therefore,

clean Filter with kerosene.

Filter in Oil tank is clogged.

After removing Handle L, pick the filter out of

Tank. And Clean Filter with kerosene.

Then check the delivery of oil again.

Not delivered

Delivered

Delivered

Not delivered

After removing one end of Connector from

the chain oil exit on Handle R, check if

the oil can be delivered to the end.

After removing the other end of Connector from

Oil pump, insert the pin portion of Crank into

the bottom of Oil pump several time and check if

the oil can be delivered to the open end of Oil pump.

Not delivered

Not delivered

Take the reverse step of disassembling.

Note:

Do not damage Connector and rubber tube to Oil tank when connecting them with Oil tank/ Handle R/ Oil pump.

Connect the above parts securely to prevent the oil leaking.

Delivered

Remove the rubber tube end to Oil tank from

Oil pump end under the condition that the oil

occupies a half in Oil tank.

Oil pump is out of order.

Replace Oil pump by the new, then check

the delivery of oil again.

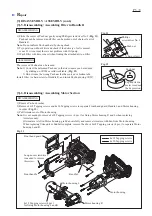

Fig. 10

chain oil exit

Fig. 8

Fig. 9

Stepped portion of Helical gear 50

Ball bearing 696ZZ

Ball bearing 609LLB

Cam

Spindle

Stop ring E-8Sprocket 9Lock washer 12

groove of Spindle

R

epair

1) As illustrated in Fig. 8, press-fit the components of Gear section.

Note:

* Helical gear 50 is directional. Therefore, press-fit Helical gear 50 so that its stepped portion can face the

direction of Ball bearing 609LLB. (

Fig. 8

)

* Cam is not directional. Press-fit Cam to the position that is in contact with Helical gear 50.

2) Insert Gear section straight into Handle R, and then fix Bearing housing to Handle R by tightening 4x18 Tapping

screws (4 pcs. ...Refer to

Fig. 3

)

3) Mount Lock washer 12 and Sprocket 9 to Spindle, and secure them by pinching Stop ring E-8 completely to the groove

of Spindle. (

Fig. 9

)

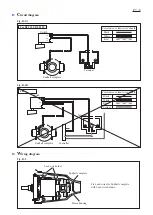

When Chain oil is not delivered, check the cause in accordance with the following flowchart and repair the machine.

1) Remove Gear section. (Refer to

[3]-3

.)

2) Pull off Crank and check if O ring 1.5 on its end of pin portion has damaged or not.

3) Pour approx. 30cc of Makita genuine chain oil (Refer to

LUBRICANT

) or

commercial oil VG32-100 to Oil tank. Rise and fall Crank by hand while checking

if Chain oil is delivered from chain oil exit designated by arrow in

Fig. 10

.

Note:

Filter in Oil tank has to be dipped into chain oil during checking.

[3] DISASSEMBLY/ ASSEMBLY (cont.)

[3]-3. Disassembling/ Assembling Gear Section

[3]-4. Disassembling/ Assembling Oil Pump Section

ASSEMBLING

DISASSEMBLING