12 ENGLISH

FUNCTIONAL

DESCRIPTION

CAUTION:

Always be sure that the tool is

switched off and unplugged before adjusting or

checking function on the tool.

Indication lamp

Only for model 9565CVR

►

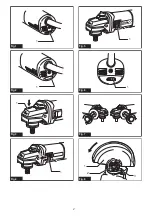

Fig.1:

1.

Indication lamp (speed adjusting dial)

Only for model 9565CR

►

Fig.2:

1.

Indication lamp

The indication lamp lights up green when the tool is

plugged.

If the indication lamp does not light up, the mains cord

or the controller may be defective.

The indication lamp is lit but the tool does not start even

if the tool is switched on, the carbon brushes may be

worn out, or the controller, the motor or the ON/OFF

switch may be defective.

Shaft lock

WARNING:

Never actuate the shaft lock when

the spindle is moving.

It may cause serious injury or

the tool damage.

Press the shaft lock to prevent spindle rotation when

installing or removing accessories.

►

Fig.3:

1.

Shaft lock

Switch action

CAUTION:

Before plugging in the tool, always

check to see that the slide switch actuates prop-

erly and returns to the "OFF" position when the

rear end of the slide switch is depressed.

CAUTION:

Switch can be locked in the "ON"

position for ease of operator comfort during

extended use. Apply caution when locking tool in

the "ON" position and maintain firm grasp on tool.

To start the tool, press down the rear end of the slide

switch and then slide it toward the “I (ON)” position.

For continuous operation, press down the front end of

the slide switch to lock it.

►

Fig.4:

1.

Slide switch

To stop the tool, press down the rear end of the slide

switch so that it returns to the “O (OFF)” position.

►

Fig.5:

1.

Slide switch

Speed adjusting dial

Only for model 9565CVR

The rotation speed of the tool can be changed by turning

the speed adjusting dial. The table below shows the num

-

ber on the dial and the corresponding rotation speed.

►

Fig.6:

1.

Speed adjusting dial

Number

Speed

1

2,800 min

-1

2

4,000 min

-1

3

6,500 min

-1

4

9,000 min

-1

5

12,000 min

-1

NOTICE:

If the tool is operated continuously at

low speed for a long time, the motor will get over-

loaded, resulting in tool malfunction.

NOTICE:

The speed adjusting dial can be turned

only as far as 5 and back to 1. Do not force it past

5 or 1, or the speed adjusting function may no

longer work.

Accidental re-start preventive function

When plugging in the tool while the switch is ON, the

tool does not start.

At this time, the indication lamp blinks in red and shows

that the accidental re-start preventive function works.

To start the tool, turn off the switch, and turn it on again.

Soft start feature

Soft start feature reduces starting reaction.

Constant speed control

Possible to get fine finish, because the rotating speed is

kept constantly even under the loaded condition.

Overload protector

When the load on the tool exceeds admissible levels,

power to the motor is reduced to protect the motor from

overheating. When the load returns to admissible lev-

els, the tool will operate as normal.

ASSEMBLY

CAUTION:

Always be sure that the tool is

switched off and unplugged before carrying out

any work on the tool.

Installing side grip (handle)

CAUTION:

Always be sure that the side grip is

installed securely before operation.

Screw the side grip securely on the position of the tool

as shown in the figure.

►

Fig.7