10

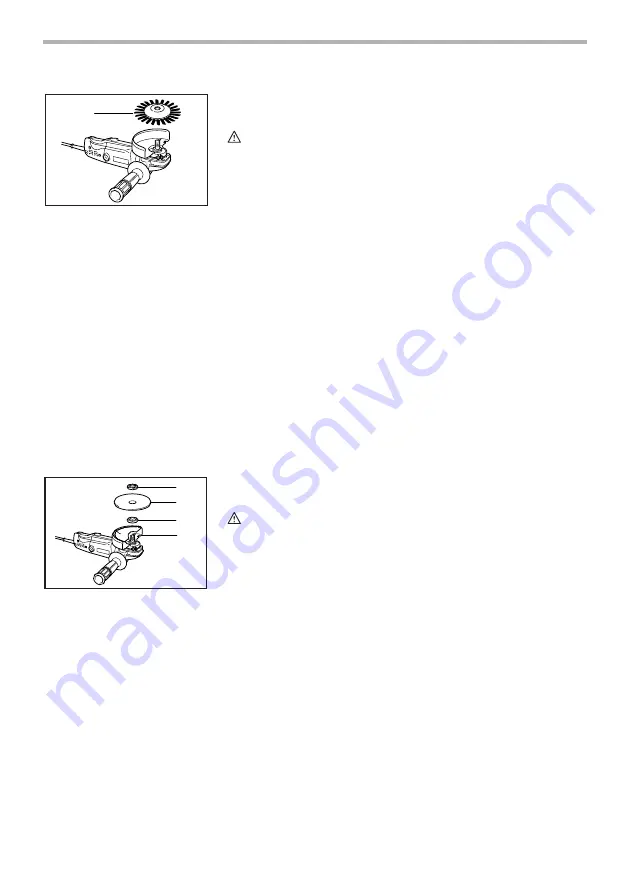

Operation with wire wheel brush

(optional accessory)

CAUTION:

•

Check operation of wire wheel brush by running tool with

no load, insuring that no one is in front of or in line with

the wire wheel brush.

•

Do not use wire wheel brush that is damaged, or which

is out of balance. Use of damaged wire wheel brush

could increase potential for injury from contact with

broken wires.

•

ALWAYS use guard with wire wheel brushes, assuring

diameter of wheel fits inside guard. Wheel can shatter

during use and guard helps to reduce chances of

personal injury.

Unplug tool and place it upside down allowing easy access

to spindle. Remove any accessories on spindle. Thread wire

wheel brush onto spindle and tighten with the wrenches.

When using wire wheel brush, avoid applying too much pres-

sure which causes over bending of wires, leading to prema-

ture breakage.

Operation with abrasive cut-off wheel

(optional accessory)

WARNING:

•

When using an abrasive cut-off wheel, be sure to use

only the special wheel guard designed for use with cut-

off wheels.

•

NEVER use cut-off wheel for side grinding.

During cutting operations, never change the angle of the

wheel. Placing side pressure on the cut-off wheel (as in

grinding) will cause the wheel to crack and break, causing

serious personal injury.

1. Wire wheel brush

1

001228

1. Lock nut

2. Abrasive cut-off wheel

3. Inner flange

4. Wheel guard for cut-off wheel

001116

1

3

2

4