6 ENGLISH

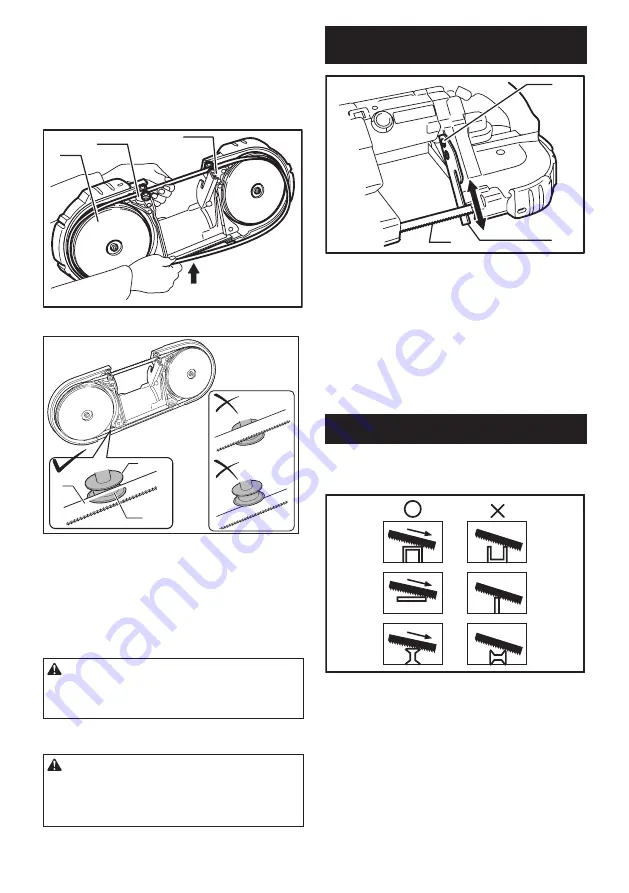

Insert the blade between the bearings of the upper

holder first and then into the lower holder. The blade

back should contact the bearings in the lower portion of

the upper holder and lower holder.

Position the blade around the wheels and insert the

other side of the blade within the upper holder and

lower holder until the blade back contacts the bottom of

the upper holder and lower holder.

1

2

3

4

►

1.

Upper holder

2.

Lower holder

3.

Wheel

4.

Press

1

2

3

►

1.

Blade guide

2.

Groove

3.

Blade

Put the blade into the groove in the blade guide.

Hold the blade in place and turn the blade-tightening

lever counterclockwise until it hits against the protrusion

on the frame. This places proper tension on the blade.

Make sure that the blade is correctly positioned within

the blade guard and around the wheels.

Start and stop the tool two or three times to make sure

that the blade runs properly on the wheels.

CAUTION:

•

While making sure that the blade runs on the

wheels properly, keep your body away from the

blade area.

To remove the blade, follow the installation procedure

in reverse.

CAUTION:

•

When turning the blade tightening lever clock-

wise to release the tension on the blade, point

the tool downward because the blade may come

off unexpectedly.

Adjusting the protrusion of stopper

plate

1

3

2

A

B

►

1.

Screw

2.

Stopper plate

3.

Blade

Protrusion of the stopper plate to the blade can be

adjusted.

In the ordinary operation, protrude the stopper plate to

the A side fully.

When the stopper plate strikes against the obstacles

like a wall or the like at the finishing of a cut, loosen two

screws and slide it to the B side in the figure.

After sliding the stopper plate, secure it by tightening

two screws firmly.

OPERATION

It is important to keep at least two teeth in the cut.

Select the proper cutting position for your workpiece by

referring to the figure.