38

5. DAILY MAINTENANCE & LUBRICATION

5.1. DAILY CHECKS

5.1.1.

CRITICAL: Check all hardware daily before operation. Tighten hardware to torque values as

specified in the Torque Chart, page 82 unless otherwise specified in this manual.

IMPORTANT NOTE: To prevent mounting kit hardware from loosening during operation always torque

mounting kit hardware to specified torque noted in loader operator manual. Check bolt torque every 25

hours of loader operation.

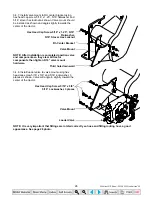

Check torque on these 14 bolts and all other

mounting kit hardware after every 25 hours of

operation

Center Casting Hardware should be torqued to 172

ft. lbs.

Check torque value in the Torque Chart, page 82 for

Front Rail Hardware

Engine Rail Hardware should be torqued to 107 ft.

lbs.

IMPORTANT

0595-3087

To keep mounting kit hardware

from loosening during loader

operation, hardware must be

torqued to specifications noted

in operator manual.

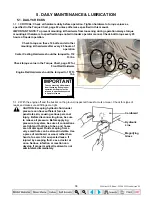

5.1.2. With the engine off and the bucket on the ground, inspect all hoses for cuts or wear. Check for signs of

leaks and make sure all fittings are tight.

CAUTION: Escaping hydraulic fluid under

pressure can have sufficient force to

penetrate skin, causing serious personal

injury. Before disconnecting lines, be sure

to relieve all pressure. Before applying

pressure to system, be sure all connections

are tight and that lines, tubes, and hoses

are not damaged. Fluid escaping from a

very small hole can be almost invisible. Use

a piece of cardboard or wood, rather than

hands, to search for suspected leaks. If

injured by escaping fluid, see a doctor at

once. Serious infection or reaction can

develop if proper medical treatment is not

administered immediately.

Cardboard

Hydraulic

Line

Magnifying

Glass

35 Series 4WD, Model - 3535 & 4035 Loader June’08