46

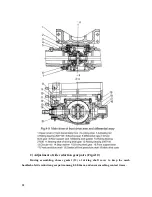

depth is reached, adjust the clearance between lowering stop block (3) and stop pin (4). After

adjustment, fix stop block (3) on return push rod (5) with bolt and nut, then raise the

implement several times to check the adjustment.

If the implement is provided with a supporting wheel, the floating control needs to be

used. Meanwhile, adjust lowering stop block (3) to the position where control lever1 (1) of

distributor (valve) will not return to neutral position.

③

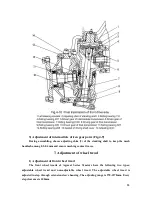

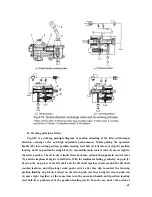

Adjustment of lowering speed

During adjustment, the lowering speed of the implement can be adjusted through

rotating the adjusting valve bolt (5) (see Fig.4-18). When the lowering speed is suitably

adjusted, use check screw (4) to limit the moving range of adjusting valve bolt.

④

Adjustment of safety valve

Safety valve has been adjusted before leaving the factory. In general, dismounting in

operation is not permitted anyhow. If the readjustment is necessary, it should be done on

special pressure test stand. The oil for test is HC-8(SY1152-77), the oil temperature should be

±

℃

controlled as 65

5

. When the press screw plug of safety valve is rotated clockwise, the

higher opening pressure is got, or vise versa.

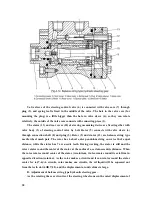

In hydraulic system, as the precision of many parts is high, and the assembly parts have

been carefully tested and adjusted, cleanliness of the hydraulic oil, cleaning oil and the

environment should be especially paid attention to during operation, maintenance and fixing

the breakdowns. Generally free dismount is not allowed.

Notes: Before starting the engine, make sure there is enough oil in the lifter housing, so

as to avoid damage to the hydraulic gear pump.

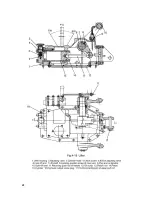

10. Use and adjustment of air brake device of trailer

Summary of Contents for JINMA-200

Page 14: ...9 Fig 2 1 Controls and Instruments ...

Page 41: ...36 ...

Page 47: ...42 ...

Page 66: ...61 3 Distribution diagram of rolling bearing and transmission system of Jm series tractors ...

Page 67: ...62 ...

Page 71: ...66 ...