TWIN F 3.0 A / TWIN F 3.0 U

D1 5002BA1-GB01

37

9 CHAPTER 9 - MAINTENANCE

O

NLY TRAINED PERSONNEL WHO KNOW HOW THE LIFT WORKS

,

MUST BE

ALLOWED TO SERVICE THE LIFT

To service properly the lift, the following has to be carried out:

•

use only genuine spare parts as well as equipment suitable for the work

required

•

follow the scheduled maintenance and check periods shown in the manual

•

discover the reason for possible failures such as too much noise, overheating,

oil blow-by, etc.

•

Refer to documents supplied by the dealer to carry out maintenance:

•

functional drawing of the electric and hydraulic equipment

•

exploded views with all data necessary for spare parts ordering

•

list of possible faults and relevant solutions.

B

EFORE CARRYING OUT ANY MAINTENANCE OR REPAIR ON THE LIFT

,

DISCONNECT THE POWER SUPPLY

,

PADLOCK THE GENERAL SWITCH AND KEEP

THE KEY IN A SAFE PLACE TO PREVENT UNAUTHORISED PERSONS FROM

SWITCHING ON OR OPERATING THE LIFT

.

9.1 Ordinary

maintenance

The lift has to be properly cleaned at least once a month. Use self-cleaning clothes.

T

HE USE OF WATER OR INFLAMMABLE LIQUID IS STRICTLY FORBIDDEN

.

Be sure the rod of the hydraulic cylinders is always clean and not damaged since this

may result in leakage from seals and, as a consequence, in possible malfunctions.

9.2 Periodic

maintenance

Every 3 months

Hydraulic circuit

- check oil tank level; refill with oil, if

needed;

- check the circuit for oil leakage. Check

seals for proper conditions and replace

them, if necessary.

Foundation bolts:

- check bolts for proper tightening

Hydraulic pump

- verify that no noise changes take place

in the pump of the control desk when

running and check fixing bolts for proper

tightening

Safety system

- check safety devices for proper

operation

Every 6 months

Oil:

Check oil for contamination or ageing.

Contaminated oil is the main reason for

failure of valves and shorter life of gears

Summary of Contents for Twin Series

Page 4: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 II ...

Page 6: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 IV ...

Page 8: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 VI ...

Page 10: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 VIII ...

Page 14: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 4 ...

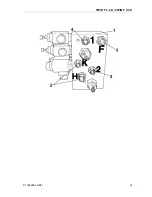

Page 19: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 9 Figure 2 LIFT ...

Page 21: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 11 Figure 3 CONTROL DESK ...

Page 34: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 24 ...

Page 45: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 35 ...

Page 46: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 36 ...

Page 51: ......