TWIN F 3.0 A / TWIN F 3.0 U

D1 5002BA1-GB01

29

•

Press DOWN button (6) until the lift stops automatically (Figure 3);

N

OTE

:

IF LOWERING IS NOT CARRIED OUT BY THE LIFT OR THE LIFT IS BLOCKED BEFORE THE

DETECTION BY THE SAFETY HEIGHT LIMIT SWITCH

,

OIL IN EXCESS FROM SECONDARY CYLINDERS

MUST BE REMOVED

.

If the lift does not low, push at the sametime with the down button (6) the oil discharge

button (13) and immediately release it.

W

ARNING

!

C

ARRY OUT THIS OPERATION ONLY AND EXCLUSIVELY WHEN THE LIFT

IS WITHOUT CHARGE

.

•

Press the SAFETY down button (7) (Ref. Figure 3).

•

If the runways are not levelled, restart bleeding operations (as described

previously).

7.6 Checks and inspections

7.6.1 Mechanical

checks

•

grease sliding seats of blocks placed under platforms and on bases;

•

platform levelling and alignment (as per measurement showed on Figure 18);

•

lift fixing to the ground with 8 anchor bolts (Ref. Figure 18) (min. recommended

size

ø = 16 mm

), bolts, connectors and connections tightened.

•

clean all parts of the machine

Figure 18 - FIXING ON THE GROUND

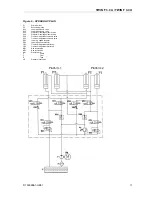

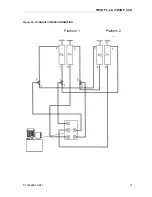

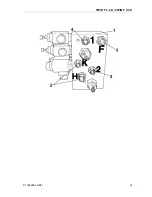

7.6.2 Electrical

checks

•

connections as per diagrams

•

lift

grounding

•

operation of the following devices:

top position limit switch

bottom position limit switch

P1 levelling

P2 levelling

Summary of Contents for Twin Series

Page 4: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 II ...

Page 6: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 IV ...

Page 8: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 VI ...

Page 10: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 VIII ...

Page 14: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 4 ...

Page 19: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 9 Figure 2 LIFT ...

Page 21: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 11 Figure 3 CONTROL DESK ...

Page 34: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 24 ...

Page 45: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 35 ...

Page 46: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 36 ...

Page 51: ......