1

46-620 B73 & Series 75 Liquid Level Switche

s

1.0

Installation

Caution:

If equipment is used in a manner not specified by manu-

facturer, protection provided by equipment may be

impaired.

1.1

Unpacking

Unpack the instrument carefully. Inspect all units for

damage. Report any concealed damage to carrier within

24 hours. Check the contents of the packing slip and

purchase order. Check and record the serial number for

future reference when ordering parts.

1.2

Critical Alarm Function

It is recommended that for critical alarm functions, an

additional level switch be installed as a high–high or

low–low level alarm for maximum protection.

1.3

Piping

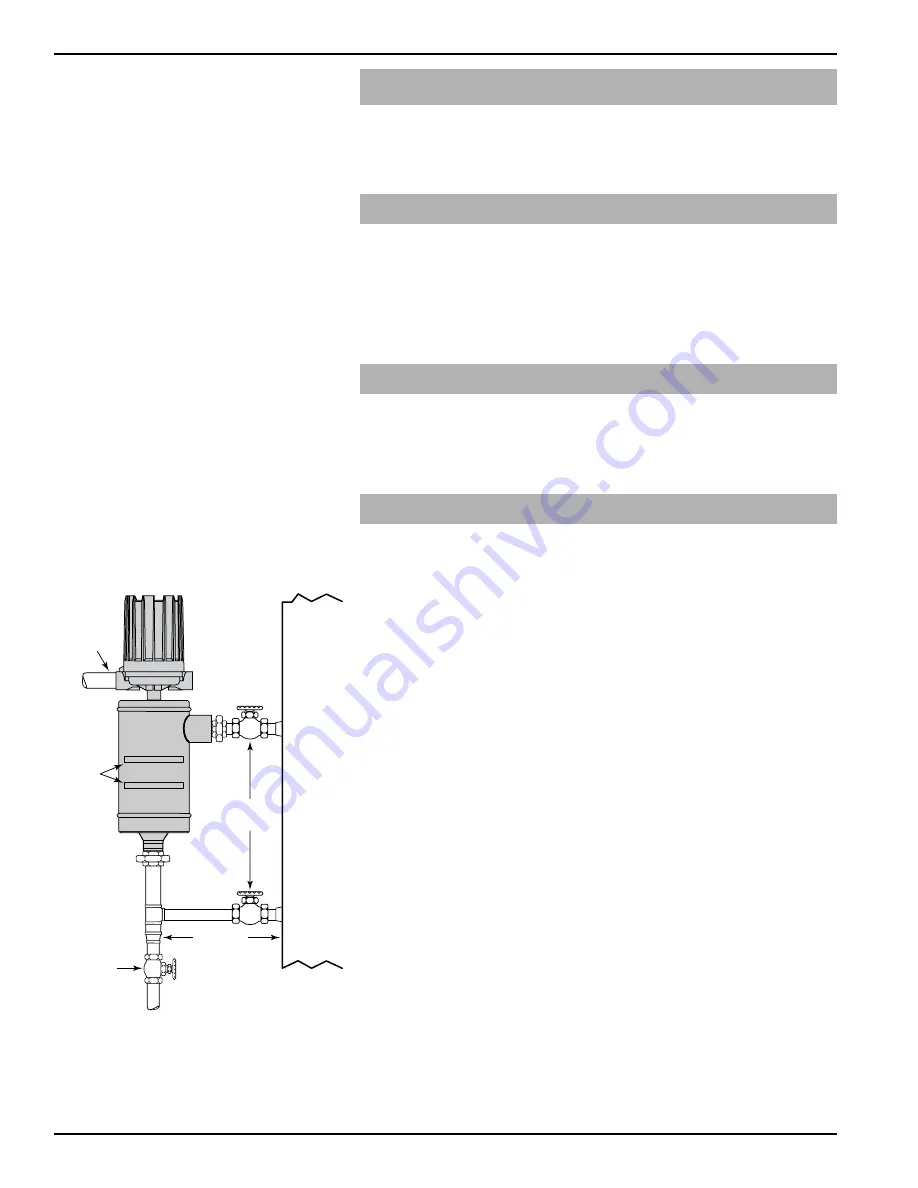

Figure 3 shows a typical piping installation of a Magnetrol

B73 and Series 75 control to a pressure vessel. Level decals

on control identify the actuation levels for a unit with a

single switch at minimum specific gravity. See

Section 5.2,

Physical

on page 17 for the actuation levels.

Use pipe of sufficient strength to support the control. If

necessary, provide a stand or hanger to help support its

weight. All piping should be straight and free of low spots

or pockets so that lower liquid line will drain towards the

vessel and upper vapor line will drain toward the control.

Shut-off valves are recommended for installation between

the vessel and the control. If control is to be used with a

low temperature liquid (one which will boil in the float

chamber if outside heat is absorbed), the chamber and pip-

ing should be insulated. Such boiling in the chamber will

cause false level indications.

Caution:

Do not insulate switch mechanism housing.

On controls equipped with pneumatic switch assemblies,

consult bulletin on mechanism furnished for air (or gas)

piping instructions. See

Section 6.1.2, Switch and Housing

Reference

on page 19 for bulletin numbers for pneumatic

switches.

NOTE: D, E, and H75 models are designed for high level service only

and utilize a pressure equalizing self-purging float and stem.

Pressure in the chamber must be raised and lowered slowly to

avoid potential float collapse.

Shutoff

valve

Drain

valve

Conduit

outlet

Max. 12"

Pressure

vessel

Switch

actuating

level

reference

marks

Figure 1

Piping Configuration