10

46-620 B73 & Series 75 Liquid Level Switches

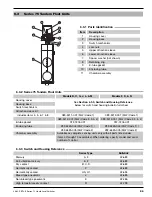

11. If differential has been changed in the field by reposition-

ing the lower jam nuts on the float stem, check tightness

and position of the jam nuts. Refer to

Figure 7

on page 5.

NOTE: Differential adjustment affects a change in the amount of level

travel between switch-on and switch-off actuations.

Do not

attempt

adjustment without first consulting factory for assis-

tance in computing level differential change for your control.

12. Check float to be certain it is buoyant in the liquid (float

chamber or vessel must have adequate liquid level). If float

is determined to be filled with liquid, or it is collapsed, it

must be replaced immediately.

Do not attempt to repair a

float.

See

Section 2.5, Tandem Float Models

on page 7.

If all components in the control are in operating condition,

the trouble must be located external to the control. Repeat

inspection of external conditions previously described.

NOTE: If difficulties are encountered which cannot be identified,

consult the factory or your local representative for assistance.

A complete description of the trouble should be provided

along with information concerning your piping and mounting

arrangement, plus a description of your operating sequence.

Sketches or photographs showing the installation are also

beneficial.

When communicating about your control, be certain to

always specify the complete Model and Serial numbers.

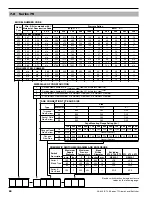

4.0

Preventive Maintenance

Periodic inspections are a necessary means to keep your

Magnetrol level control in good working order. This con-

trol is a safety device to protect the valuable equipment it

serves. A systematic program of preventive maintenance

must be implemented when the control is placed into

service. If the following is observed, your control will

provide reliable protection of your capital equipment for

many years.

4.1

What To Do

4.1.1 Keep Control Clean

Be sure the switch housing cover is always in place on the

control. This cover is designed to keep dust and dirt from

interfering with switch mechanism operation. In addition,

it protects against damaging moisture and acts as a safety

feature by keeping bare wires and terminals from being

exposed. Should the housing cover or any seals become

damaged or misplaced, obtain a replacement immediately.