3

INSTALLATION

CRITICAL ALARM FUNCTION

It is recommended that for critical alarm functions, an addi-

tional level switch be installed as a high-high or low-low

level alarm for maximum protection.

PIPING

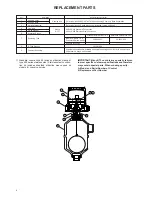

Figure 3 shows a typical piping installation of a Magnetrol

level switch to a pressure vessel. Reference mark on float

chamber should be aligned to correspond with liquid level

in vessel at which switch control is desired.

Use pipe of sufficient strength to support the control. If nec-

essary, provide a stand or hanger to help support its

weight. All piping should be straight and free of “low spots”

or “pockets” so that lower liquid line will drain towards the

vessel and upper vapor line will drain toward the control.

Shut-off valves are recommended for installation between

the vessel and the control. If control is to be used with a

lower temperature liquid (one which will “boil” in the float

chamber if outside heat is absorbed), the chamber and pip-

ing should be insulated. Such boiling in the chamber will

cause false level indications. DO NOT INSULATE SWITCH

MECHANISM HOUSING.

On controls equipped with pneumatic switch assemblies,

consult bulletin on mechanism furnished for air (or gas) pip-

ing instructions. Refer to chart on this page for bulletin num-

bers for pneumatic switches.

MOUNTING

Adjust piping as required to bring control to a vertical posi-

tion. Magnetrol controls must be mounted within three (3°)

degrees of vertical. A three degree slant is noticeable by

eye, but installation should be checked with a spirit level on

top and/or sides of float chamber.

Controls should be mounted as close to the vessel as pos-

sible. This will result in a more responsive and accurate

level change in the control. Liquid in a long line may be

cooler and more dense than liquid in the vessel causing

lower level indication in the control than actual level in the

vessel.

cable entry

Pressure

vessel

Switch

actuating

level

reference

marks

Drain

valve

Shutoff

valve

Max

305 mm

Figure 3

WIRING

Most mechanical control switch housings are designed to

allow 360° positioning of the cable entries by loosening the

set screw(s). See figure 4. On high temperature applica-

tions (above 120° C [250° F]), high temperature wire should

be used between control and first junction box located in a

cooler area.

1. To gain access to switch mechanism(s) remove switch

housing cover. (See CAUTION next page.)

2. Pull in supply wires (conductors), wrap them around

enclosing tube under the baffle plate and connect to

proper terminals. Be certain that excess wire does not

interfere with "tilt" of switch and that adequate clearance

exists for replacement of switch housing cover.

NOTE: See bulletin on switch mechanism furnished with

your control (as listed below) for proper connections.

3. Connect power supply to control and test switch action

by varying liquid level in tank or vessel.

CAUTION:

In hazardous area, do not power the unit until

the cable gland is sealed and the enclosure

cover is screwed down securely.

NOTE: If switch mechanism fails to function properly, check

vertical alignment of control housing and consult installation

instructions in switch mechanism bulletin.

4. Replace switch housing cover and place control into ser-

vice.

NOTE: If control has been furnished with an explosion proof

(cast) or moisture proof (gasketed) switch housing, check

the following:

– After wiring connections have been completed, housings

must be sealed via the correct cable gland to prevent

entrance of air.

– Check cover to base fit, to be certain gasketed joint is

tight. A positive seal is necessary to prevent infiltration of

moisture laden air or corrosive gases into switch housing.

Switch mechanism

Bulletin

Reference series

Mercury switches

42-783

A

Dry contact switches

42-683

B, C, D, U, W, X

Anti-vibration mercury switches

E

Anti-vibration dry contact switches

42-684

G, H, I

Bleed type pneumatic valve

42-685

J

Non-bleed type pneumatic valve

42-686

K