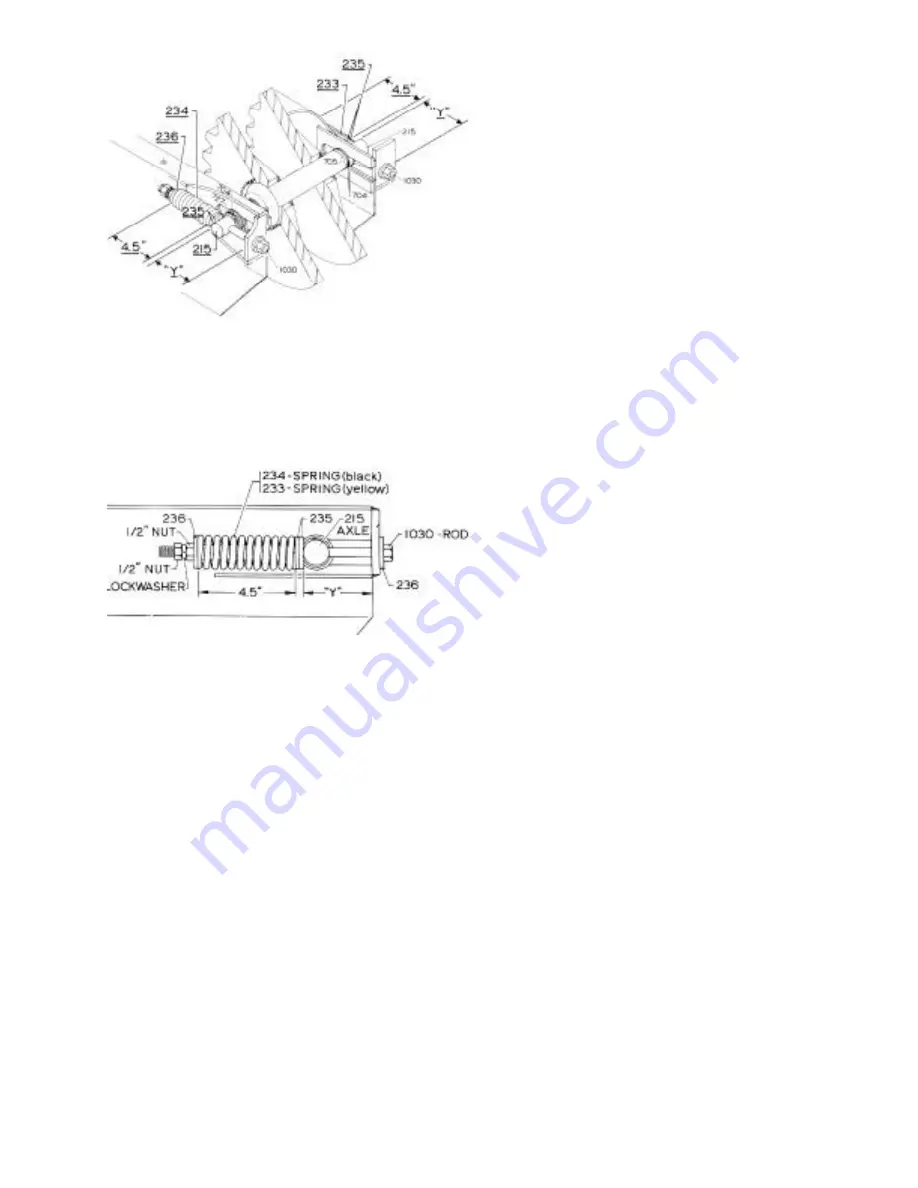

Begin your tensioning procedure by checking

the overall length of the #234 Spring (black) and

#233 Spring (yellow). Both Springs should be

compressed to an overall length of 4.5”. The

length measured is only the Spring; do not include

the #235 & #236 Washers in your measurement!

If your Springs have lost this 4.5” dimension,

or you have replaced a broken #1030 Rod, follow

this procedure:

With a wrench, rotate each #1030 Rod so that

its respective #236 Washer is drawn

forward

(or

released

r e a r w a r d

) thereby adjusting its

respective #234 Spring (black) or #233 Spring

(yellow) to a final length of 4.5”. Work back and

forth tightening each Spring 1/4” at a time until you

have achieved a 4.5” overall length for both

Springs. Measure Spring length only; don’t

include #235 and #236 Washers in your

measurement.

At this time remount and safely restart your

Crawler. Drive it approximately 25 feet forward

and then go in reverse back to your starting point.

Shut off the engine and dismount. Check the

overall length of your #233 & #234 Springs for any

changes in length. Readjust to proper 4.5” overall

length if necessary. When satisfied, secure each

1/2” Nut (on end of each #1030 Rod) with a 1/2”

Washer and 1/2” Nut...fully tighten.

NOTE

: To achieve ideal Track alignment, the

“Y” distance (the distance from the rear face of

the #215 Front Axle forward to the

rear face

of the

frame block) should be reasonably equal on each

end of the #215 Axle you are adjusting.

To accomplish this, loosen the 1/2” Nut and

1/2” Lock Washer on the end of the #1030 Rod

holding the #233 Spring (yellow) and “fine tune”

the overall length of the #233 Spring using the

procedure described above. Don’t change the

previous 4.5” setting of the #234 Spring (black).

When equal “Y” distances have been

achieved, replace and tighten the 1/2” Lock

Washer and 1/2” Nut on extreme end of #1030

Rod holding the #233 Spring (yellow).

Using original Cap Screws and Nuts, replace

the #113 Spring Guard removed above...tighten.

Lubricate system.

TRACK SPROCKET &

TRACK IDLER LUBRICATION

Lubrication

of

the

#1218

Idlers

is

accomplished by greasing through #2061 Zerk

Fittings. The Zerk Fittings are “submerged

mounted” in the outside ends of all eight of the

#213 Idler Axles and the two #214 Rear Axles and

are lubricated from the sides of the Crawler (See

drawing above)

The Front Idler Sprocket assemblies have

#2061 Zerks mounted in their Tubes and are

lubricated from the front of the track through the

1/2” track shoe gap.

It is a good idea to clean out the track system

of debris each time you lubricate to spot problems

before they become expensive maintenance

items.

TRACK IDLER MAINTENANCE

NOTE

: The #1218 Track Idlers are made of a

slightly softer steel than the Track Chain. This has

been done to allow the inevitable wear to be

concentrated on the less expensive Idlers thereby

protecting and greatly extending the life of the

much more expensive Track Chain.

The Track Idlers, after a few hours of running

time, will have their inside walls

hard-peened

into

a configuration that will precisely mate with the

contour of the Track Chain they are guiding. This