ES

FR

EN

IT

14

Madas Technical Manual

- 4|4.1b - REV. 0 of 10

th

May 2018

RG/2M

5.0 - MAINTENANCE

No maintenance operations need to be carried out inside the device.

NOTE

: if an internal inspection is required, it is recommended to:

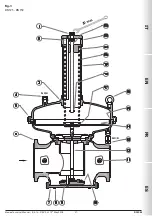

• Also check the integrity of the obturator (

9

) and, if necessary, replace the rubber seal (

10

);

• Replace the gaskets before reassembling.

• It is recommended to contact the Technical Department to check or replace the membrane(s).

• In any case, before carrying out any dismantling operation on the device, make sure that there is no pressurised

gas inside.

6.0 - TRANSPORT, STORAGE AND DISPOSAL

• During transport the material needs to be handled with care, avoiding any impact or vibrations to the device;

• If the product has any surface treatments (ex. painting, cataphoresis, etc) it must not be damaged during transport;

• The transport and storage temperatures must observe the values provided on the rating plate;

• If the device is not installed immediately after delivery it must be correctly placed in storage in a dry and clean place;

• In damp facilities, it is necessary to use driers or heating to avoid condensation.

• At the end of its service life, the product must be disposed of in compliance with the legislation in force in the country where

this operation is performed.

7.0 - WARRANTY

The warranty conditions agreed with the manufacturer at the time of the supply apply.

Damage caused by:

• Improper use of the device;

• Failure to observe the requirements described in this document;

• Failure to observe the regulations pertaining to installation;

• Tampering, modification and use of non-original spare parts;

is not covered by the rights of the warranty or compensation for damage.

The warranty also excludes maintenance work, the assembly of parts or non-original spare parts, making changes to the

device and natural wear.

8.0 - RATING PLATE DATA

The rating plate data (see example provided here) includes the following:

• Manufacturer’s name/logo and address (possible distributor name/logo)

• Mod.:

= device name/model followed

by the connection diameter

• P1 max

= Maximum pressure or inlet pressure range that product operation is guaranteed at

• P2

= Outlet pressure range

• EN 88-1

= Product reference regulation

• TS

= Temperature range that product operation is guaranteed at

•

= In compliance with ATEX Dir. followed by the protection mode

• year

= Year of manufacture

• Lot

= Product serial number (see explanation below)

• U1823

= Lot issued in year 2018 in the 23

rd

week

• 14216

= progressive job order number for the indicated year

• 00001

= progressive number referring to the quantity of the lot

Mod.: RG/2M DN 150

P1 max: 500 mbar

P2: 100

÷

250 mbar - EN 88-1 TS: -15+60 °C

year: 2018 Lot:U1823 14216/00001

Via Moratello, 5/7 - 37045

Legnago (VR) - Italy

www.madas.it