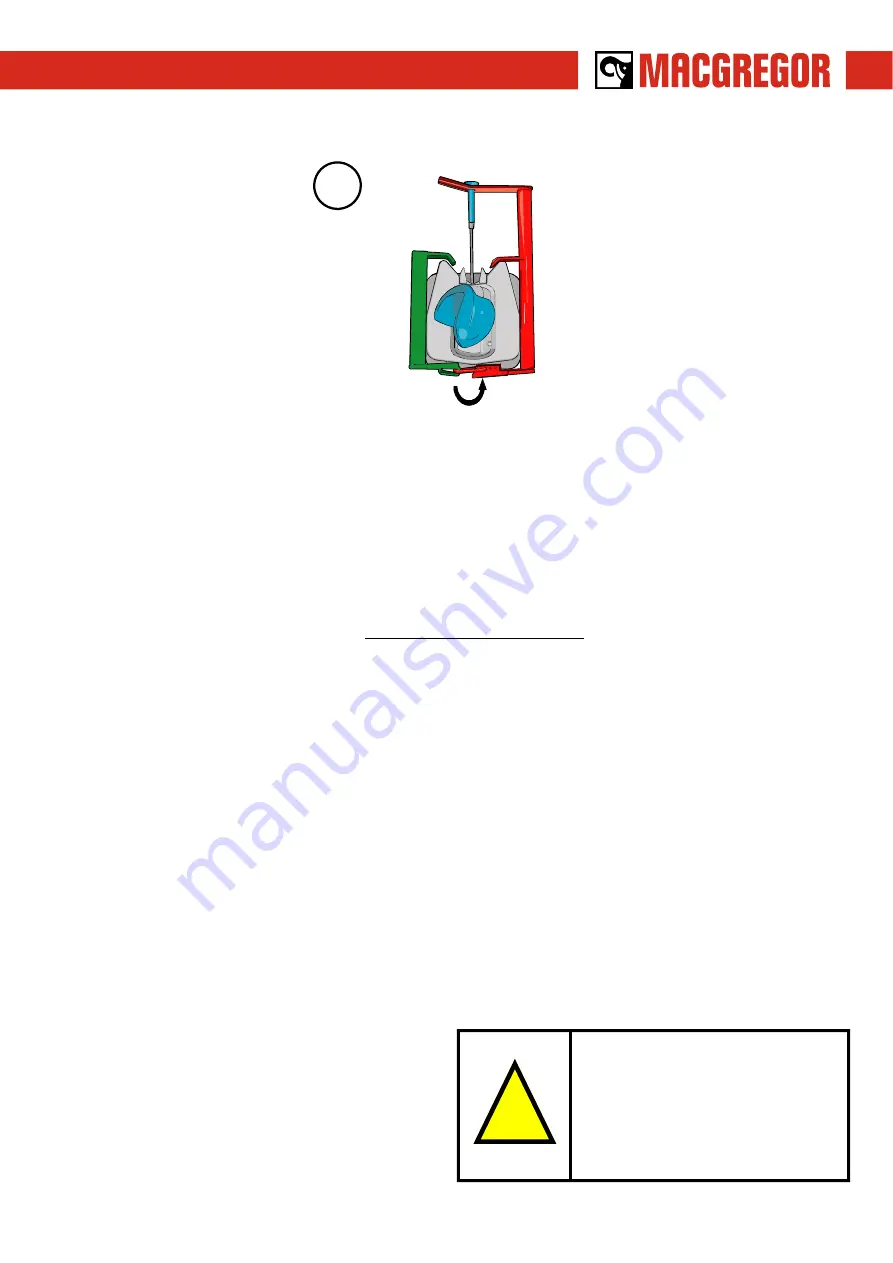

6

EMERGENCY OPERATION

!

Ensure that all arms and hooks stay

in position when locking.

Lock the tool with the latch.

The twistlock is now secured in open

position and the container can be lifted.

4

Removal of emergency tool:

To remove the emergency tool, open the latch.