5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: [email protected]

EM-9433 Rev.8 P. 1 / 8

INSTRUCTION MANUAL

BARGRAPH INDICATING ALARM

(thermocouple input)

MODEL

48NAT

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

■

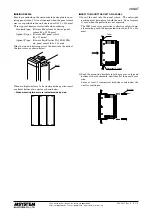

PACKAGE INCLUDES:

Bargraph indicator (body + CJC sensor, incl. scale plate) ..(1)

Mounting bracket ................................................................(2)

Bezel*

1

..................................................................................(2)

Watertight packing .............................................................(1)

*1. The size of included bezel differs depending on option code.

■

MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■

INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation, connection and

basic maintenance procedures.

POINTS OF CAUTION

■

CONFORMITY WITH EU DIRECTIVES OR UK LEGISLATION

• This equipment is suitable for Pollution Degree 2, Meas-

urement Category II (output, transient voltage 2500V)

and Installation Category II (transient voltage 2500V).

Reinforced insulation (signal input to output to power

input: 300V) is maintained. Prior to installation, check

that the insulation class of this unit satisfies the system

requirements.

• The equipment must be mounted on a panel surface.

Once mounted on a panel, take appropriate precautions

to prevent operators to be exposed to the terminal block.

• Altitude up to 2000 meters.

• Insert a noise filter for the power source connected to the

unit. TDK-Lambda Noise Filter Model RSAN-2006 or

equivalent is recommended.

• The equipment must be installed such that appropriate

clearance and creepage distances are maintained to con-

form to CE or UKCA requirements. Failure to observe

these requirements may invalidate the CE or UKCA con-

formance.

• The actual installation environments such as panel con-

figurations, connected devices, connected wires, may affect

the protection level of this unit when it is integrated in

a panel system. The user may have to review the CE or

UKCA requirements in regard to the whole system and

employ additional protective measures to ensure the CE

or UKCA conformity.

• In order to enable the operator to turn off the power in-

put immediately, install a switch or a circuit breaker ac-

cording to the relevant requirements in IEC 60947-2 and

properly indicate it.

■

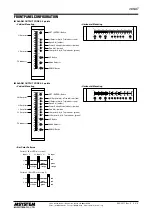

POWER INPUT RATING & OPERATIONAL RANGE

• Locate the power input rating marked on the product and

confirm its operational range as indicated below:

100 – 240V and 85 – 264V AC rating: 85 – 264V, 50/60 Hz,

approx. 5.5 – 8VA

24V DC rating: 24V ±15%, approx. 3.5W

■

GENERAL PRECAUTIONS

• Before you remove the unit or mount it, turn off the power

supply and input signal for safety.

• Be sure to put the terminal cover on while the power is

supplied.

■

ENVIRONMENT

• Indoor use.

• If the unit’s environmental protection is compromised

(e.g. when multiple units are to be mounted side by side)

when heavy dust or metal particles are present in the air,

install them inside an enclosure with a proper ventilation.

• Do not install the unit where it is subjected to continuous

vibration. Do not subject the unit to physical impact.

• Environmental temperature must be within -10 to +55°C

(14 to 131°F) with relative humidity within 30 to 90% RH

in order to ensure adequate life span and operation.

■

REQUIREMENTS TO ENSURE IP65

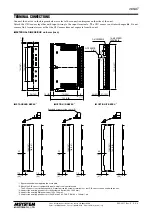

• Observe the designated panel cutout size (31.5 × 138 mm).

• Single mounting only. IP65 is not ensured when the units

are clustered side by side.

• The watertight packing included in the product package

must be placed behind the front cover.

• The mounting bracket must be fastened tightly until they

hit the panel.

• Confirm visually that the packing is not contorted or ex-

cessively run off the edge after installation.

■

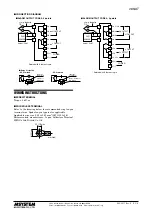

WIRING

• Do not install cables close to noise sources (relay drive

cable, high frequency line, etc.).

• Do not bind these cables together with those in which

noises are present. Do not install them in the same duct.