035-18200-000-B-1102

Unitary Products Group

13

After the supply air blower motor is operating, adjust

the resistances in both the supply and the return duct

system to balance the air distribution throughout the

conditioned space. The job specification may require

that this balancing be done by someone other than the

equipment installer.

To check the supply air CFM after the initial balancing

has completed”

1.

Drill two 5/16” holes in the side panel as shown in

Figure 15.

2.

Insert at lest 6” of 1/4” tubing into each of these

holes for sufficient penetration into the air flow on

both sides of the indoor coil.

NOTE:

The tubes must be inserted and held in a posi-

tion perpendicular to the air flow so that veloc-

ity pressure will not affect the static pressure

reading.

3.

Using an inclined manometer, determine the pres-

sure drop across a dry indoor coil. Since moisture

on the coil may vary greatly, measuring the pres-

sure drop across a wet coil under field conditions

would be inaccurate. To assure a dry coil, the heat

pump system should be de-activated while the test

is being run.

4.

Knowing the pressure drop across a dry coil the

actual CFM through the unit can be determined

from the curve in Fig. 16.

If the CFM is above or below the specified value, the

supply air motor pulley may have to be re-adjusted.

After one hour of operation, check the belt and pulleys

for tightness and alignment.

After readings have been obtained remove the tubes

and seal up the drilled holes in the side panel. Dot

plugs (5/16” - P/N 029-13880-000) are available

through Source One Parts ordering procedures.

NOTE:

Shut down the heat pump system before tak-

ing any test measurements to assure a dry

indoor coil.

TABLE 6: SUPPLY AIR BLOWER MOTOR PULLEY

ADJUSTMENT

TURNS

OPEN

DRIVE RANGE

625-810 RPM

827-986 RPM

5

625

827

4

662

859

3

699

891

2

736

923

1

773

955

0

810

986

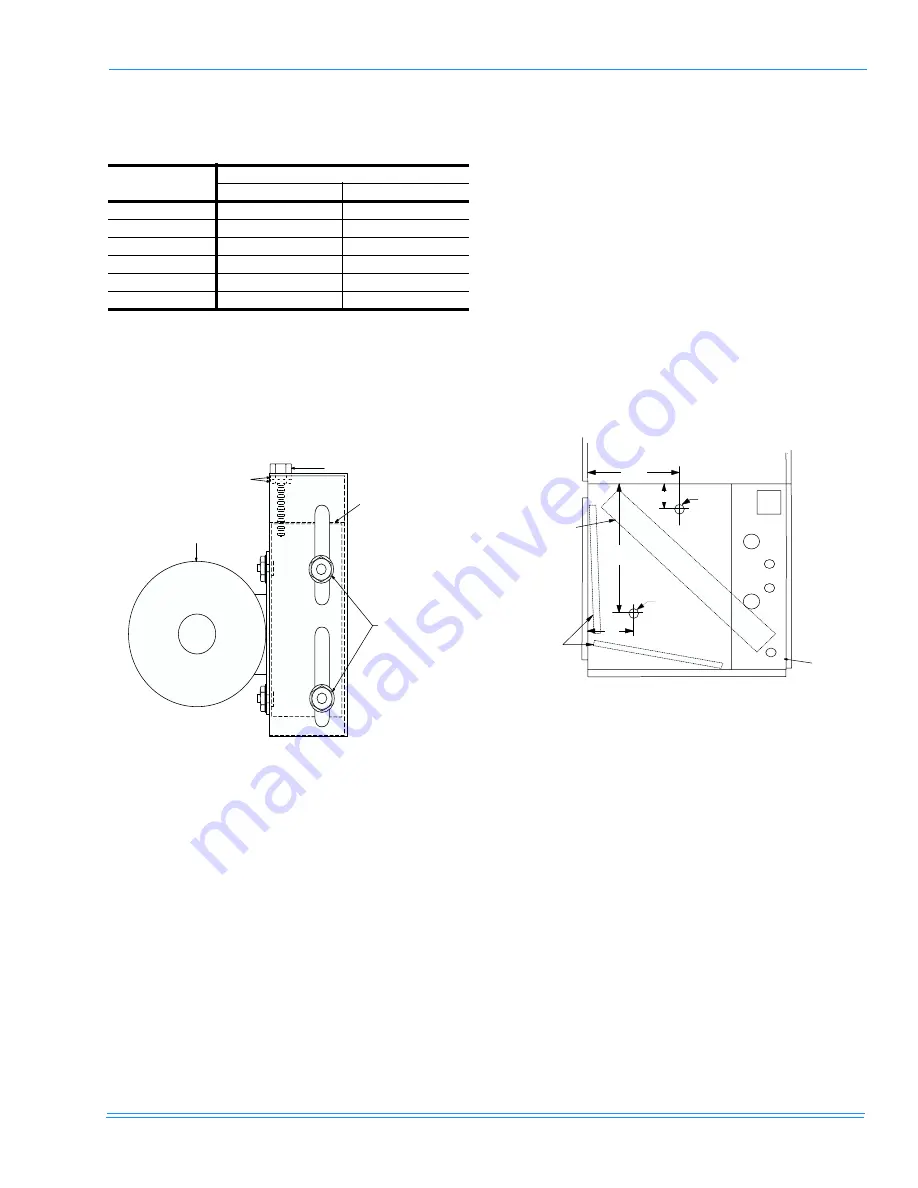

FIGURE 14: TYPICAL MOTOR MOUNTING

ASSEMBLY

B

A

(DO NOT LOOSEN)

MOTOR

MOTOR MOUNT

C

FIGURE 15: HOLE LOCATIONS FOR PRESSURE

DROP READINGS

5 / 1 6 "

H O L E

5 / 1 6 "

H O L E

1 8 "

7 "

2 2 "

1 0 "

E V A P O R A T O R

C O I L

F I L T E R S

C O I L S E C T I O N