Maintenance

Maintenance intervals

46

© Lutz-Jesco GmbH 2014

BA-10103-02-V01

Stepper Motor-driven Diaphragm Dosing Pump

MEMDOS SMART LK

Operating instructions

12

Maintenance

Lutz-Jesco dosing pumps are produced to the highest quality standards

and have a long service life. Nevertheless, some of their parts are subject

to wear due to operation (e.g. diaphragms, valve seats, valve balls). This

means that regular visual inspections are necessary to ensure a long

operating life. Regular maintenance will protect the dosing pump from

operation interruptions.

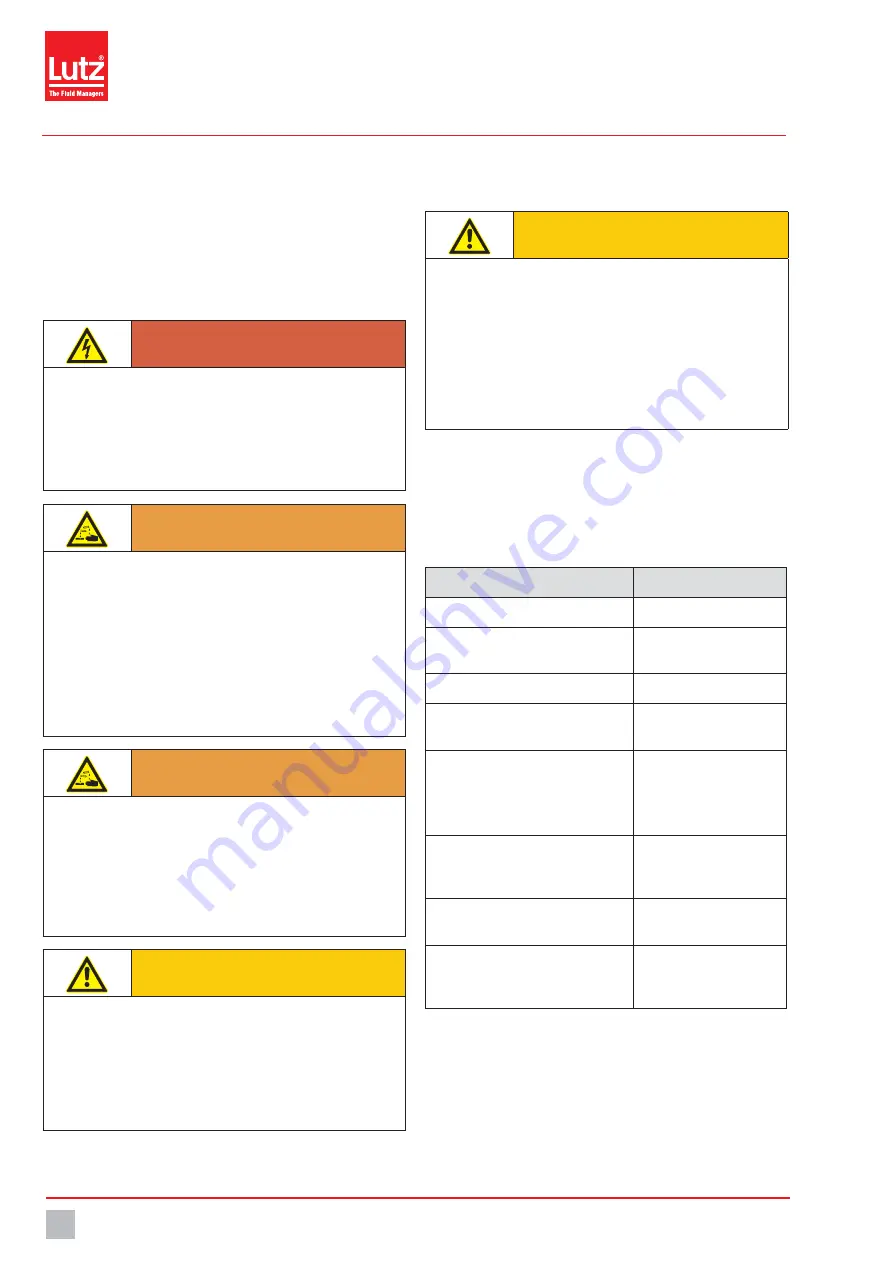

DANGER

Mortal danger from electric shock!

Live parts can infl ict fatal injuries.

Before carrying out any maintenance work, always disconnect the

dosing pump from the power supply.

Secure the dosing pump from accidental power-up.

WARNING

Caustic burns or other burns through dosing media!

While working on the dosing head, valves and connections, you may

come into contact with dosing media.

Use suffi cient personal protective equipment.

Rinse the dosing pump with a medium (e.g. water) which does not

pose any risk.

Release pressure in hydraulic parts.

Never look into open ends of plugged pipelines and valves.

WARNING

Caustic burns or other burns through dosing media!

After connecting the mains supply, residual dosing media in the

dosing head can spray out.

Before connecting the mains supply, connect the dosing lines.

Check that all the screw connections have been tightened

correctly and are leak-proof.

CAUTION

Danger of personal injury and material damage!

The dosing pump can generate a pressure that is many times the

rated one. The dosing medium can escape in the case of material

failure or wear on the dosing head, the connection pipe or the seals

that are used.

Carry out maintenance work at the recommended intervals.

CAUTION

Increased risk of accidents due to insuffi cient qualifi ca-

tion of personnel!

Dosing pumps and their accessories may only be installed, operated

and maintained by personnel with suffi cient qualifi cations. Insuffi cient

qualifi cation will increase the risk of accidents.

Ensure that all action is taken only by personnel with suffi cient and

corresponding qualifi cations.

Prevent access to the system for unauthorised persons.

12.1 Maintenance intervals

This table gives you an overview of maintenance work and the intervals

at which you must carry it out. The next few chapters contain instructions

for carrying out this work.

Maintenance work to be carried out

Frequency

Check that piping is seated fi rmly

Regularly

Check that suction and discharge

valves are seated fi rmly

Regularly

Clean suction and discharge valves

Regularly

Check that electrical connections are

not damaged

Regularly

Tighten up dosing head bolts

Regularly

Before initial commissioning

After each diaphragm

change

Check diaphragm for leakage due to

rupture

Regularly (as long as no leak

monitoring system is

installed)

Check that the installed accessories are

functioning correctly

Regularly

Check the dosing pump for unusual

noises during operation, unusual

temperatures or smells

Regularly

Tab. 41: Maintenance information and maintenance intervals