7.31

Model 644E-42/944E-42

Rev. 6/04

Engine: Cummins 4BT 3.9, B4.5T and QSB 4.5T

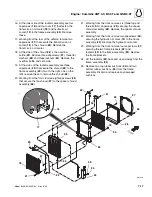

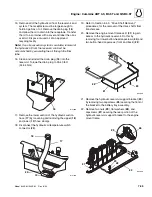

3. Loosen the lower clamp (7) attaching the flex

pipe (8) to the muffler (9). Loosen and remove the

two screws (10) securing the bracket (11) to the

muffler (9). Remove the four screws (12 and 13), six

washers (14 and 15) and two nuts (16) securing the

muffler (9) to the frame. Remove the muffler.

4. Loosen the upper clamp (17) on the flex pipe, and

remove the flex pipe (8). Loosen the V-band

clamp (18) securing the exhaust pipe (19) to the

turbo outlet (20). Remove the exhaust pipe.

7.9.2

Exhaust System Installation

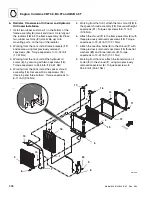

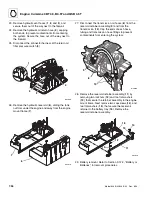

1. Install the turbo outlet exhaust pipe (19) onto the

engine turbocharger outlet (20). Install, but do not

tighten, the V-band clamp (18) around the turbo

outlet exhaust pipe. Align the elbow (23) (bend)

portion of the exhaust pipe, so that the pipe is

parallel (24) with the frame of the vehicle. Secure the

exhaust pipe (17) to the Turbo outlet (18) by

tightening the V-band clamp (16). Torque the V-band

clamp to 4-5 lb-ft (6-7 Nm).

2. Install the muffler bracket (11) to the frame. Apply

Loctite® 242 (blue) to the screws and loosely secure

bracket in place with two screws (12), four washers

(14) and two nuts (16).

3. Slide the front muffler bracket (21) onto the hanger

on the frame (22). Apply Loctite® 242 (blue) to the

screws and loosely secure front of muffler in place

with two screws (13) and washers (15).

4. Lift the rear of the muffler into place. Apply Loctite®

242 (blue) to the screws and secure rear of the

muffler to the bracket with two screws (10). Torque

screws to 19-38 lb-ft (26-52 Nm).

5. Slide the flex pipe (8) between the muffler (9) and

the exhaust pipe (19). Align the flex pipe (8) with the

muffler (9) and the exhaust pipe (19). Correct

alignment between the flex pipe (8) and exhaust

pipe (19) will have been achieved when the center

lines (25) and (26) of each is aligned. This must be

done when viewing the exhaust system from the

rear (25) and side (26) of the vehicle. Secure the

muffler (9) and muffler bracket (11) to the frame.

Torque screws to 19-38 lb-ft (26-52 Nm).

6. Secure the flex pipe (8) to the muffler (9) and the

exhaust pipe (19). Torque the clamp bolts to

45-60 lb-ft (61-81 Nm).

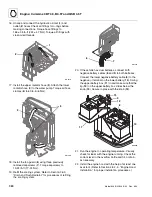

7. If the vehicle has dual batteries, connect both

negative battery cables (1 and 2) to both batteries.

Connect the lower negative battery cable (1) to the

negative (-) terminal on the lower battery (3). Swing

the upper battery box (6) in and make sure that the

lip (5) on the upper battery box slides below the

knob (4). Secure in place with the knob (4).

MU2072

7

8

17

12

13

14

9

15

16

18

19

20

Front

10

11

21

22

MU5411

23

24

25

26

Rear View

Side View

Summary of Contents for 944E-42

Page 1: ......

Page 2: ......

Page 14: ...Safety Practices 1 8 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 102: ...Boom 3 56 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 139: ...4 37 Model 644E 42 944E 42 Rev 6 04 Cab and Covers This Page Intentionally Left Blank...

Page 144: ...Cab and Covers 4 42 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 265: ...8 15 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 269: ...8 19 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 273: ...8 23 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 277: ...8 27 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 281: ...8 31 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 285: ...8 35 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 289: ...8 39 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 293: ...8 43 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 297: ...8 47 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 301: ...8 51 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 407: ...8 157 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 425: ...8 175 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 501: ...8 251 Model 644E 42 944E 42 Rev 6 04 Hydraulic System MT1950 2 3 4 5 6 7 8 5 5...

Page 507: ...8 257 Model 644E 42 944E 42 Rev 6 04 Hydraulic System MT1950 1 2 3 4 5 6 7 4 4...

Page 508: ...Hydraulic System 8 258 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 525: ...9 17 Model 644E 42 944E 42 Rev 6 04 Electrical System This Page Intentionally Left Blank...

Page 554: ...Electrical System 9 46 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 759: ...10 3 Model 644E 42 944E 42 Rev 6 04 Stabil TRAK System This Page Intentionally Left Blank...

Page 765: ...10 9 Model 644E 42 944E 42 Rev 6 04 Stabil TRAK System This Page Intentionally Left Blank...

Page 785: ...10 29 Model 644E 42 944E 42 Rev 6 04 Stabil TRAK System This Page Intentionally Left Blank...

Page 800: ...Stabil TRAK System 10 44 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 832: ...Transfer Carriage 11 32 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 840: ...12 8 Model 644E 42 944E 42 Rev 6 04 Index...

Page 841: ...Accident Prevention Tags OS2180 8990403 Origin 5 00 Accident Prevention Tags...

Page 842: ...Accident Prevention Tags OS2180 8990403 Origin 5 00...

Page 843: ......

Page 844: ......