LOUP ELITE YIELD MONITOR • OPERATION MANUAL

6

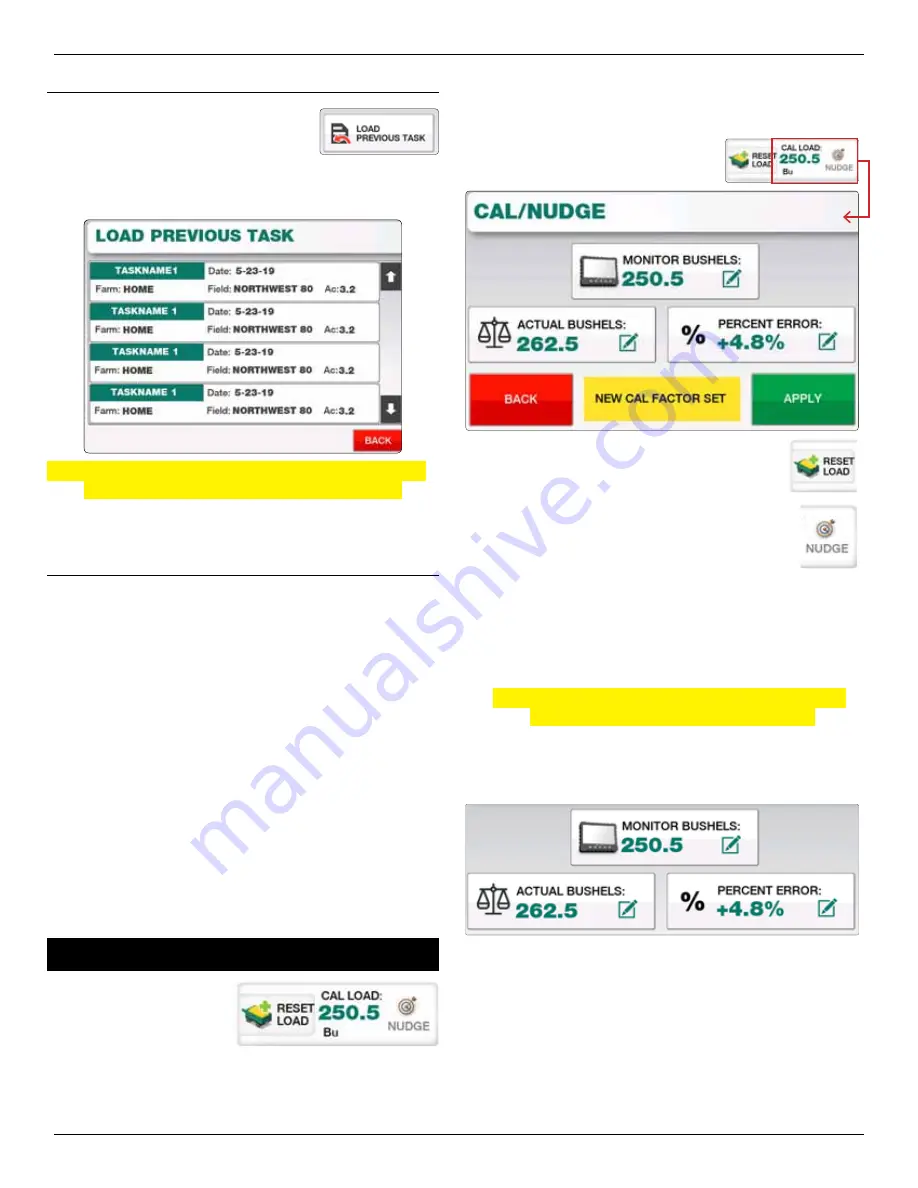

3.6 LOAD A pREvIOus TAsk

If you wish to resume a previously started

task, from the Tasks & Logging screen

select the “Load Previous Task” button. A

popup window will display with all previous tasks. Select the task

you wish to resume to load it into the Tasks & Logging screen.

You may now select “Start Task” to continue logging to that task.

Note: If the task resides on a different SD card, that card will

need to be inserted before the task can be resumed.

3.7 CLIMATE fIELDvIEW

If using Climate Fieldview and the Climate Drive/iPad Cab App,

the logging process described above is optional. Logged files

stored to the SD card by Loup Elite can be later uploaded into the

Climate Data Inbox. Alternatively data can be streamed directly

from Loup Elite to the Climate Drive.

1. Ensure GPS signal is received into Loup Elite.

2. Ensure the Climate Drive is connected using the 4 pin

deutsch connector.

3. Ensure the iPad/Cab App has connected to your Drive.

4. Setup your Combine and Header Widths accordingly

withinn the Climate Cab App.

With Elite and Climate connected you can start logging harvest

maps as per normal through the Cab App environment.

4.0 yield nudge/cal

The Yield Nudge button

and Load Bushels are

located in the upper left

corner. This window is used

differently depending if Loads Management is On or Off. By

default Loads Management is off and this calibration window

displays a single resettable “Cal Load” to be used towards a Yield

Nudge. When Loads Management is On, this window is instead

an incrementing load counter with the calibration process

done within the Loads Page. The following steps will guide you

through the calibration process for both of these options.

4.1 YIELD NuDgE

(LOAD MANAgEMENT Off)

1. Press the “Reset Load” button in the upper left

corner to ensure the “Cal Load” reads 0.0

before you start harvesting.

2. Proceed cutting the first calibration load, when

finished, either write down the bushels recorded

by the monitor or select the “NUDGE” button to

immediately perform the Yield Nudge.

If you intend to keep harvesting while you wait for the actual

bushels of your calibration load, be sure to write down the

“Cal Load” bushels displayed on screen so that you can enter

this later when performing the nudge.

Note: The header must be in the up position and the Log

stopped in order to perform the Yield Nudge.

3. When selecting the Nudge button, a popup will display with

readings for Monitor Bushels, Actual Bushels, and Percent

Error.

4. Ensure the “Monitor Bushels” are displaying the correct

amount from step 2 or re-enter the bushels if needed.

Next enter the “Actual Bushels” into the coresponding

field, doing so will display the Percent Error value between

Monitor and Actual bushels. You may also enter a Percent

Error value if you’d prefer to nudge the yield up or down by a

certain percentage.

5. Select the “Apply” button to save the calibration and “Back”

to exit this page and complete the Yield Nudge process.