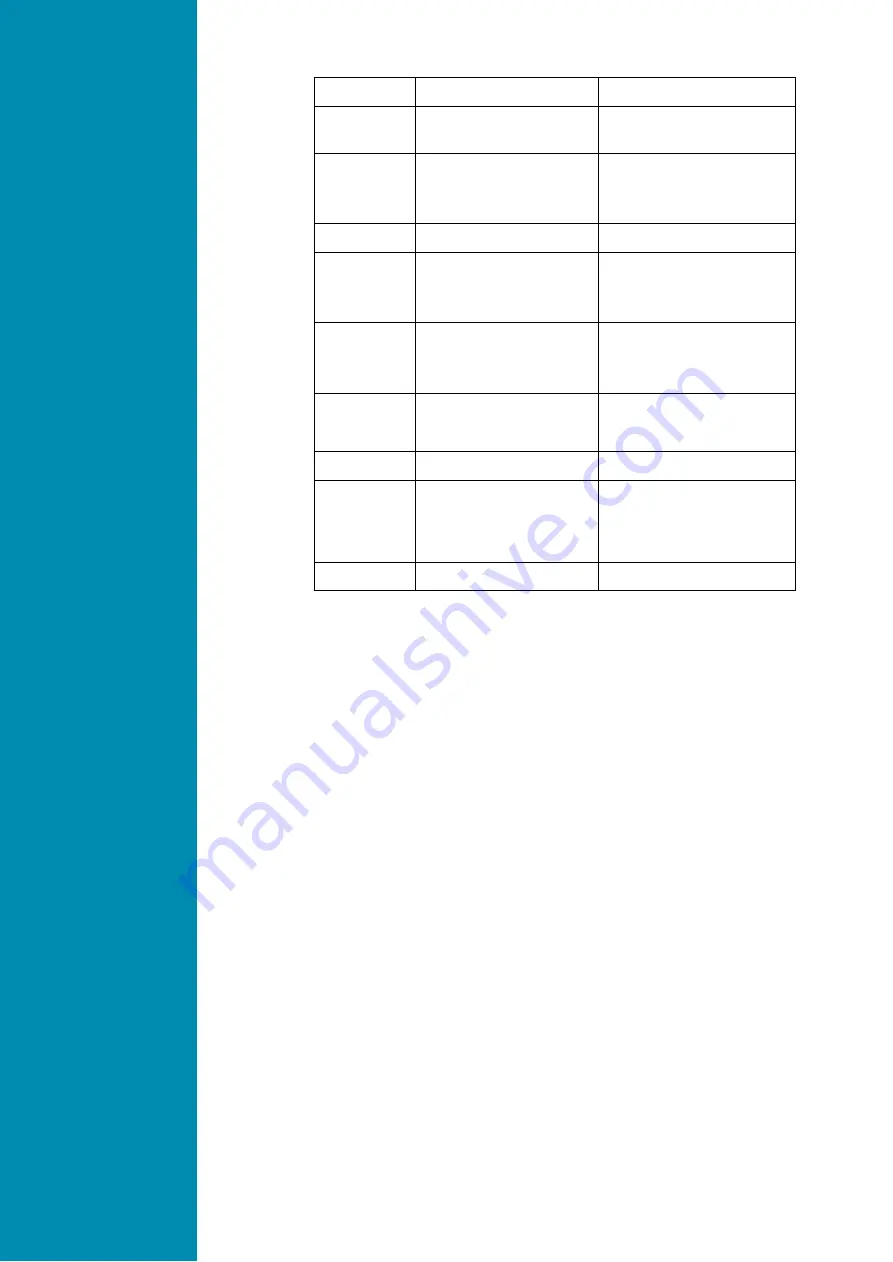

3.4

Troublesh-

ooting

Trouble

Possible Reason

Suggested Remedy

Torch will not come

on

1.Power switch OFF

2.Air supply is not of sufficient volume

or pressure

3. Work piece ground clamp not attached.

1.Turn power switch to the ON position

2. Check air supply

(5 Bar, 150 L/min)

3. Attach to work piece or to steel table with

work piece securely clamped to table

Sparks are shooting

upward instead of

down through the

material.

1.Plasma torch is not piercing the

material

2. Torch may be too far away from the

work piece

3. Material may not be earthed properly

4. Travel speed too fast

1. Increase current

2. Decrease the distance of your torch to the

work piece

3. Check connections for proper earth

4. Reduce speed

Beginning of cut not

completely pierced

Possible earth connection problem

Check all connections

Dross build-up on

parts of cuts

1. Tool/material building up heat

2. Cutting speed too slow or current too

high

3. Worn torch parts

1. Allow material to

cool then continue

cut.

2. Increase speed and/or reduce current until

dross is reduced to minimum

3. Inspect

and

repair or replace

worn parts

Arc stops while

cutting

1. Cutting speed too slow

2. Torch is too high, away from material

3. Worn torch parts

4. Work piece earth cable disconnected

1. Increase speed until problem solved

2. Lower torch to recommended height

3. Inspect

and

repair or replace

worn parts

4. Connect work piece earth clamp

to

work piece or steel table.

Insufficient

penetration

1.Cutting

speed too fast

2. Torch tilted too much

3.Metal too thick for plasma capacity

4. Worn torch parts

1.Slow down travel speed

2. Adjust

tilt

3. Several passes may be necessary

4. Inspect

and

repair or

replace worn parts

Arc sputters/flares

Water in the air supply

Install air

drier

or additional

filtration

Consumables wear

quickly

1. Exceeding unit capability

2. Excessive ARC starting HF use

3. Improperly assembled torch

4. Inadequate air supply, pressure too low

5. Faulty air compressor

1. Material too thick, increase angle to

prevent blow back into torch tip

2. See section

‘Replacing Consumables’

3. Check air filters,

increase air pressure

4. Check

air compressor operation and

make sure input air pressure is at

least

100

PSI

Circuit breaker/fuse

trips while operating

Extension

cord

being used is not

heavy duty

Use a heavy duty extension cord (at least

2.5mm2 section)

If you have any problems in setting up or operating the machine, please rst re-consult this manual.

3.5

Operation

environment

▲ Height above sea level ≤1000 M

▲ Operation temperature range -10°+40°C

▲ Air relative humidity is below 90 %( 20°C)

▲ Preferable site the machine some angles above the oor level, the maximum angle does not

exceed 15

�

.

▲ Protect the machine against heavy rain AND against direct sunshine.

▲ The content of dust, acid, corrosive gas in the surrounding air or substance cannot exceed normal

standard.

▲ Take care that there is sufcient ventilation during welding. There must be at least 30cm free

distance between the machine and wall.

3.6

Operation

Notices

▲ Read Section 1 carefully before starting to use this equipment.

▲ Ensure that the input is single-phase: 50/60Hz, 110V/220V ±10%.

▲Before operation, none concerned people should not be around the working area and especially

children. Do not watch the arc in unprotected eyes.

▲ Ensure good ventilation of the machine to improve Duty Cycle.

▲ Turn off the engine when the operation nished for energy consumption efciency.

▲When power switch shuts off protectively because of failure. Don’t restart it until problem is resolved.

Otherwise, the range of problem will be extended.

▲In case of problems, contact your local dealer if no authorized maintenance staff is available!

Summary of Contents for GRAND CUT 40 PFC MV

Page 17: ......